Centrifugal fan and air fluid machinery using the same

A centrifugal fan and air technology, which is applied to the parts of the elastic fluid pumping device, mechanical equipment, liquid fuel engine, etc., can solve the problem of loud noise, reduce the efficiency of air supply, and the shape of the blade inlet cannot follow the suction flow, etc. problem, to achieve the effect of high efficiency and low noise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0054] First, with regard to the centrifugal fan which is the first embodiment of the present invention and the fan filter unit which is an example of an air fluid machine using it, an attached figure 1 ~ attached Figure 5 Explain in detail.

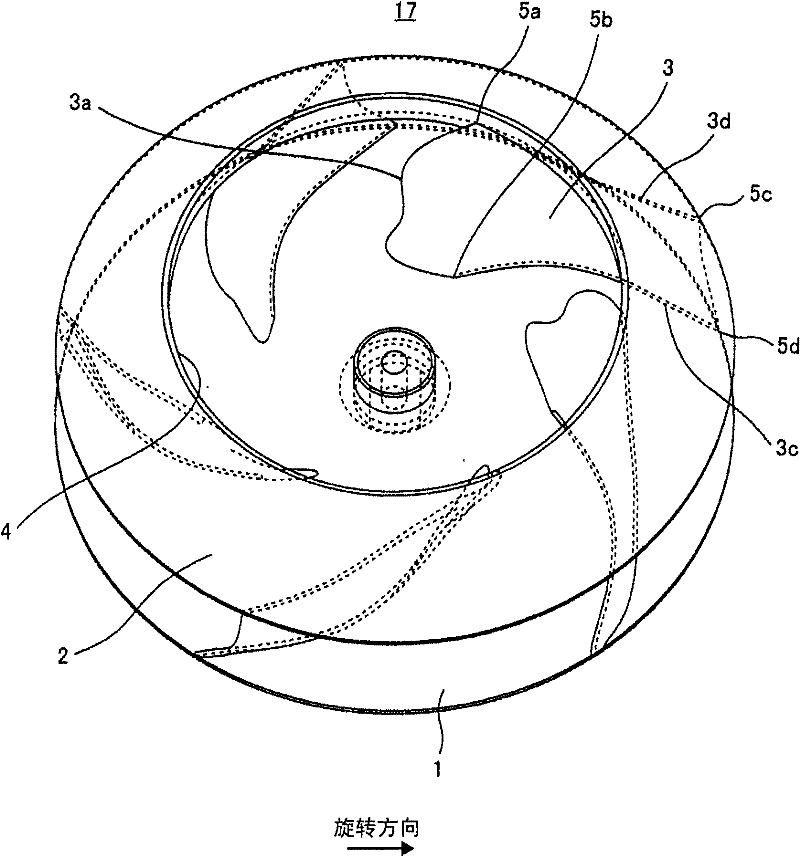

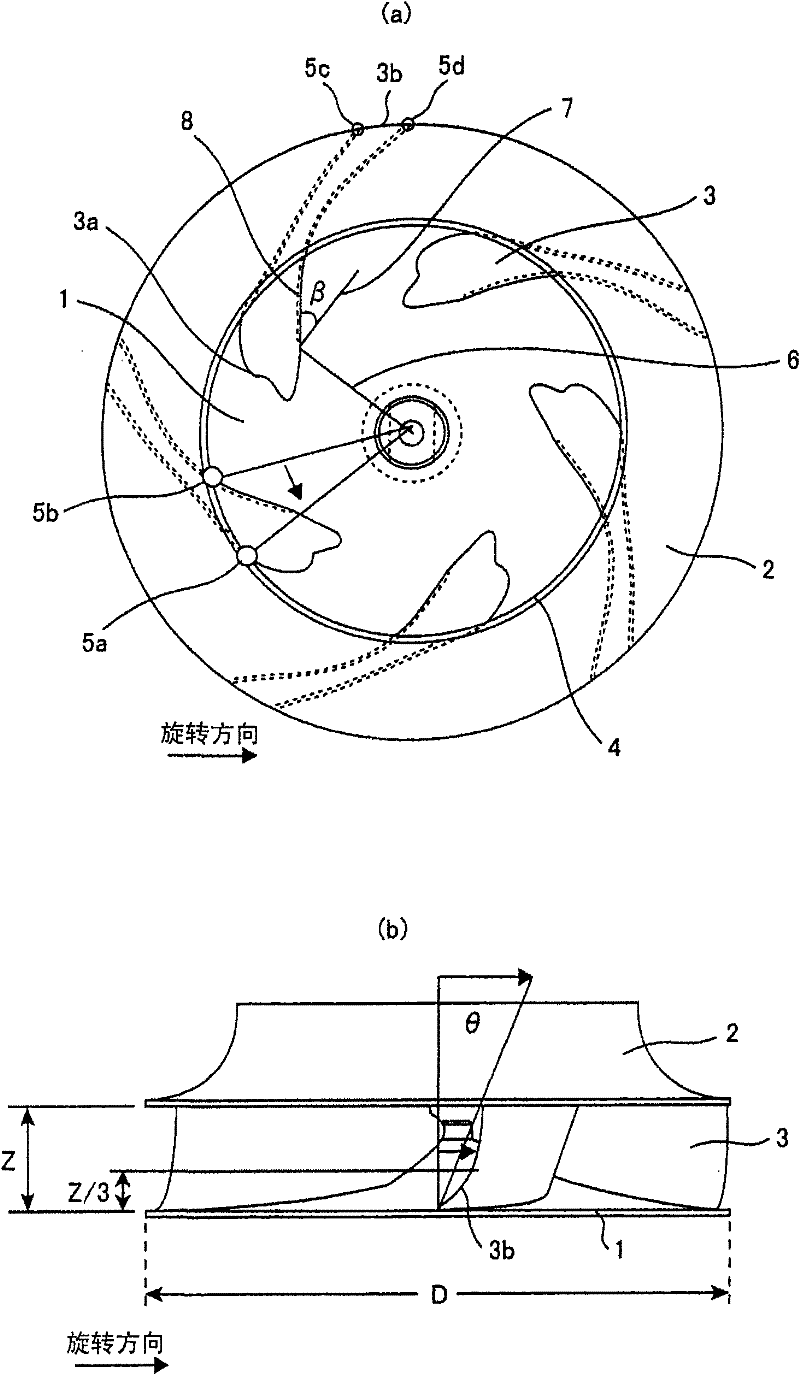

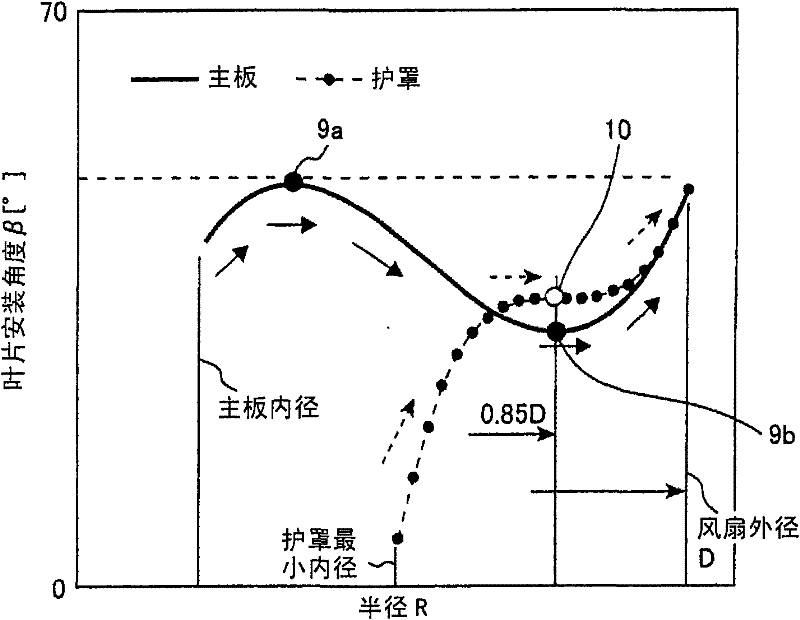

[0055] figure 1 It is a perspective view showing a centrifugal fan 17 provided with blades according to the present invention, figure 2 (a) represents its front view, and, figure 2 (b) shows its side view. and, image 3 Indicates the contact surface between the blade 3 and the shroud constituting the centrifugal fan 17 according to the present invention (refer to Figure 4 3d) and the contact surface with the motherboard (refer to Figure 4 3c) Diagram of the blade installation angle. further, Figure 4 yes figure 1 A side view of the blade 3 of the centrifugal fan 17, and, attached Figure 5 A cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com