Unclamping device on drilling rod joint

A drill pipe joint and locking device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient torque, low work efficiency, large torque inertia, etc., and achieve strong pressure consistency and work. Efficient, torque-accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

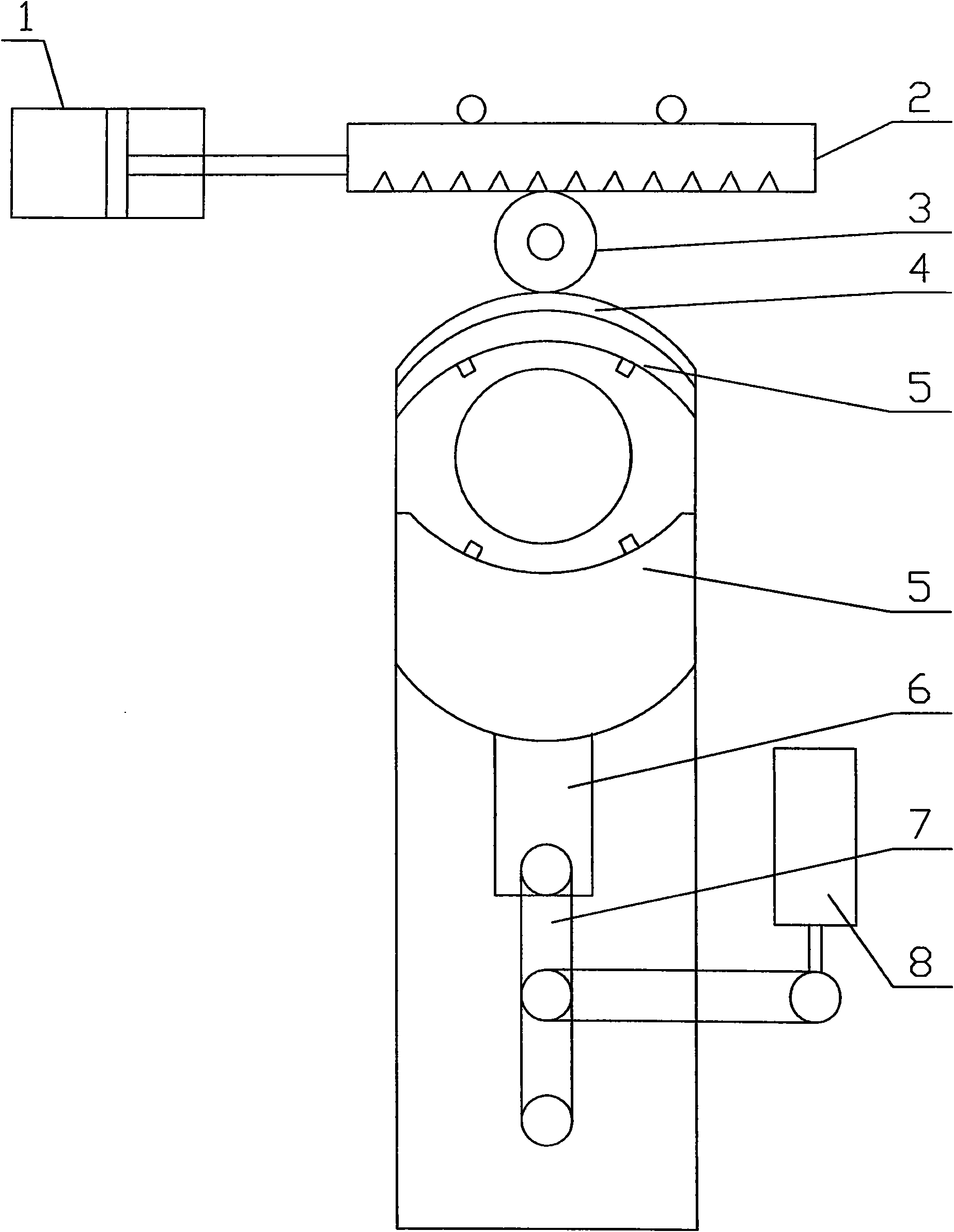

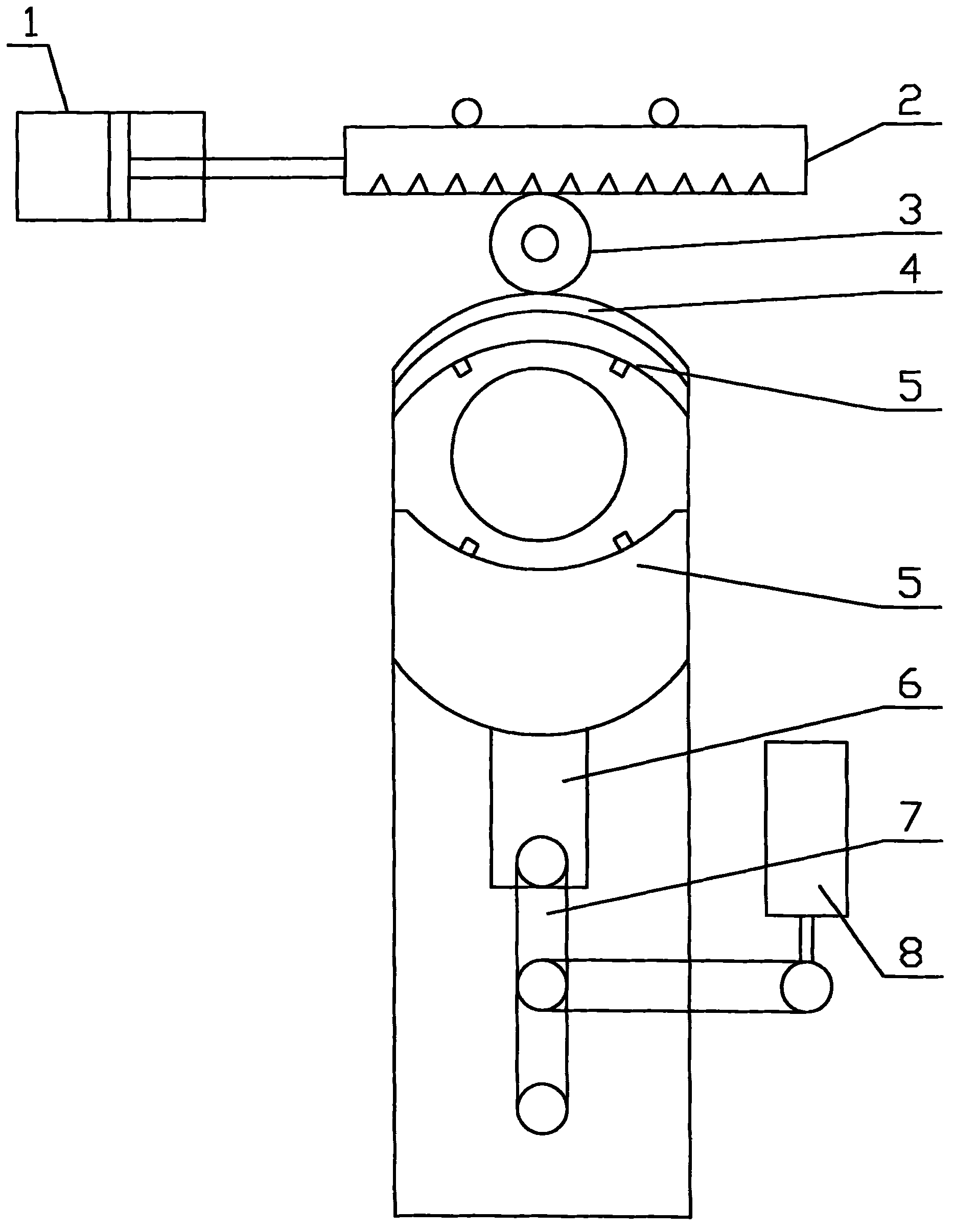

[0013] see figure 1 , The breakout device for drill pipe joints involved in the present invention is mainly composed of cylinder I 1, rack 2, transition gear 3, semicircular gear 4, locking device 5, slider 6, connecting rod 7 and cylinder II 8.

[0014] Described oil cylinder I 1 is connected with tooth bar 2, and described tooth bar 2 is meshed with the transition gear 3 below it, and described transition gear 3 is meshed with the semicircle gear 4 below it, and the locking of described semicircle gear 4 and its bottom The device 5 is connected, and the slider 6 is connected under the locking device 5, and the slider 6 is connected with the oil cylinder II 8 through the connecting rod 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com