Paper color online detecting system for paper production line

A detection device and production line technology, applied in the field of measurement systems, can solve the problems of reduced production efficiency, defective products, high humidity, etc., and achieve the effects of improving product quality and production efficiency, facilitating inquiries, and compensating for light transmittance of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

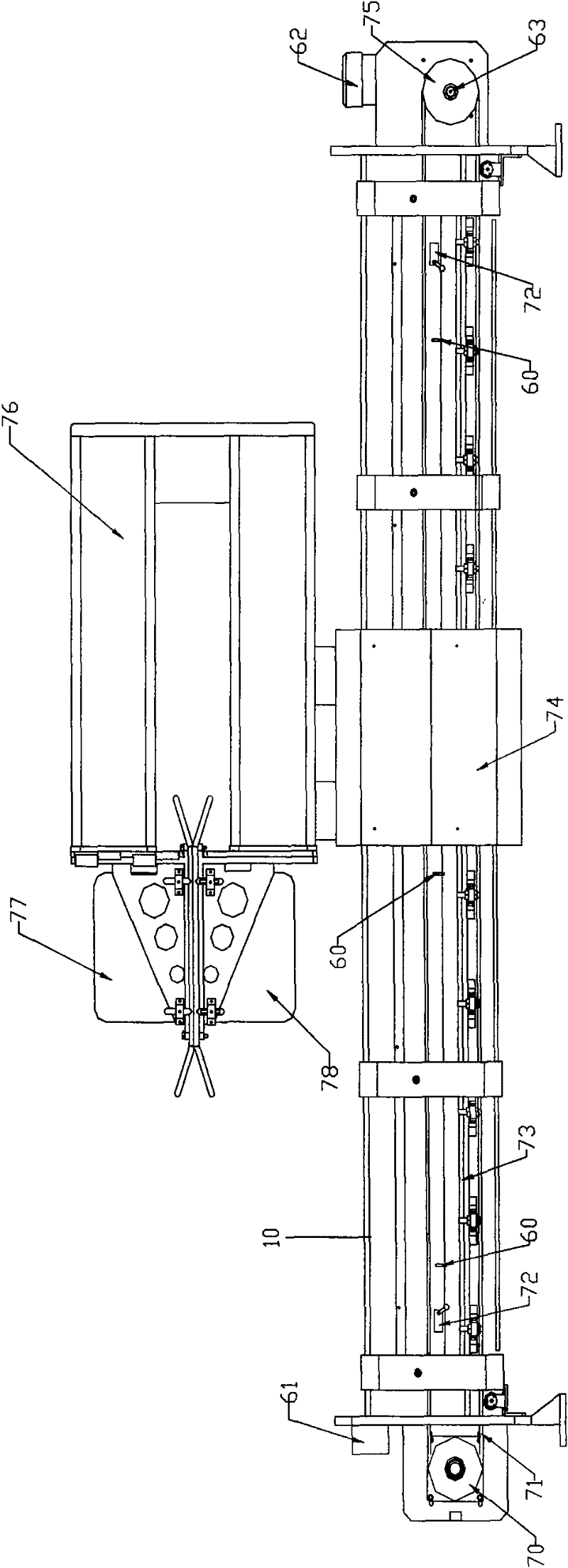

[0048] Such as figure 1 As shown, a frequency converter 61 is installed at one end of the scanning frame beam 10, a motor 62 is installed at the other end, a driving wheel 75 is installed on the motor shaft, and a driven wheel 70 is installed at one end of the frequency converter 61, between the driving wheel 75 and the driven wheel 70 There is a toothed belt 71 to connect. The middle of the toothed belt 71 is connected on the dolly 74. A pair of linear guide rails 73 are installed on the beam 10 of the scanning frame, and a slide block on the linear guide rails 73 supports a trolley 74 . A C-shaped frame 76 is installed on the trolley 74, and a detection chamber 77 and a detection chamber 78 are installed on the C-shaped frame 76, wherein the detection chamber 77 is equipped with a detection head, and the detection chamber 78 is equipped wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com