Method and device for zero point calibration of gas pressure sensor

A gas pressure and zero point calibration technology, which is applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of heavy workload, complicated operation, and high cost, and achieve the effects of reducing workload, simple operation, and reducing calibration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

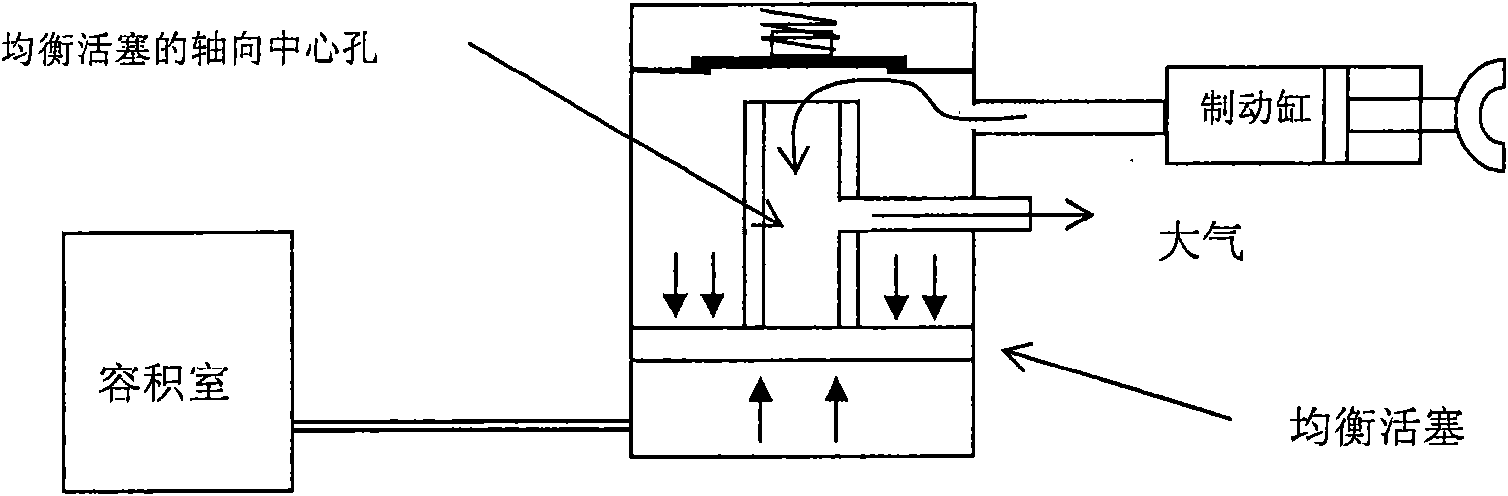

[0043] An embodiment of the present invention provides a zero point calibration method for a gas pressure sensor, Figure 4 is the flowchart of the method, such as Figure 4 As shown, the method includes:

[0044] Step 401, when the brake cylinder is relieved, obtain the pressure value of the brake cylinder;

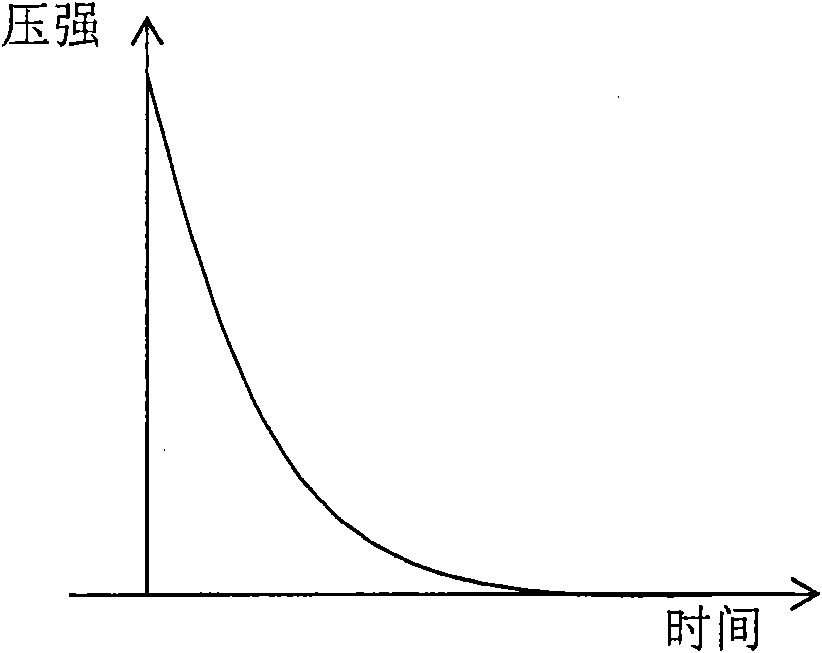

[0045] Step 402, according to the time when the pressure value is obtained and the pressure value, it is judged whether the relief process is normal;

[0046] Step 403, when the relief process is normal, it is judged whether the pressure value of the brake cylinder reaches zero;

[0047] Step 404, when the pressure value of the brake cylinder reaches zero, compare the currently obtained pressure value with the pre-stored comprehensive error nominal value;

[0048] Step 405, when the currently acquired pressure value is less than or equal to the nominal value of the integrated error, use the currently acquired pressure value as the zero point correction value;

[0049...

Embodiment 2

[0118] The embodiment of the present invention also provides a gas pressure sensor zero point calibration device, Figure 8 is the structural block diagram of the device, such as Figure 8 As shown, the device includes:

[0119] A pressure acquisition unit 1, configured to acquire the pressure value of the brake cylinder and the moment when the pressure value is acquired;

[0120] The first judgment unit 2 is connected to the pressure acquisition unit 1, and is used to judge whether the relief process is normal according to the time and pressure value of the pressure value acquired by the pressure acquisition unit 1;

[0121] The second judging unit 3 is connected to the first judging unit 2, and is used to judge whether the pressure value of the brake cylinder reaches zero when the relief process is normal;

[0122] The comparison unit 4 is connected to the pressure acquisition unit 1 and the second judgment unit 3, and is used to combine the pressure value currently acquir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com