Method for controlling inking units and/or dampening units

An inking and ink zone technology, which is applied in the field of controlling inking devices and/or wetting devices in printing presses, can solve problems such as difficulty in erroneous adjustment, and achieve the effect of simplifying the cause.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

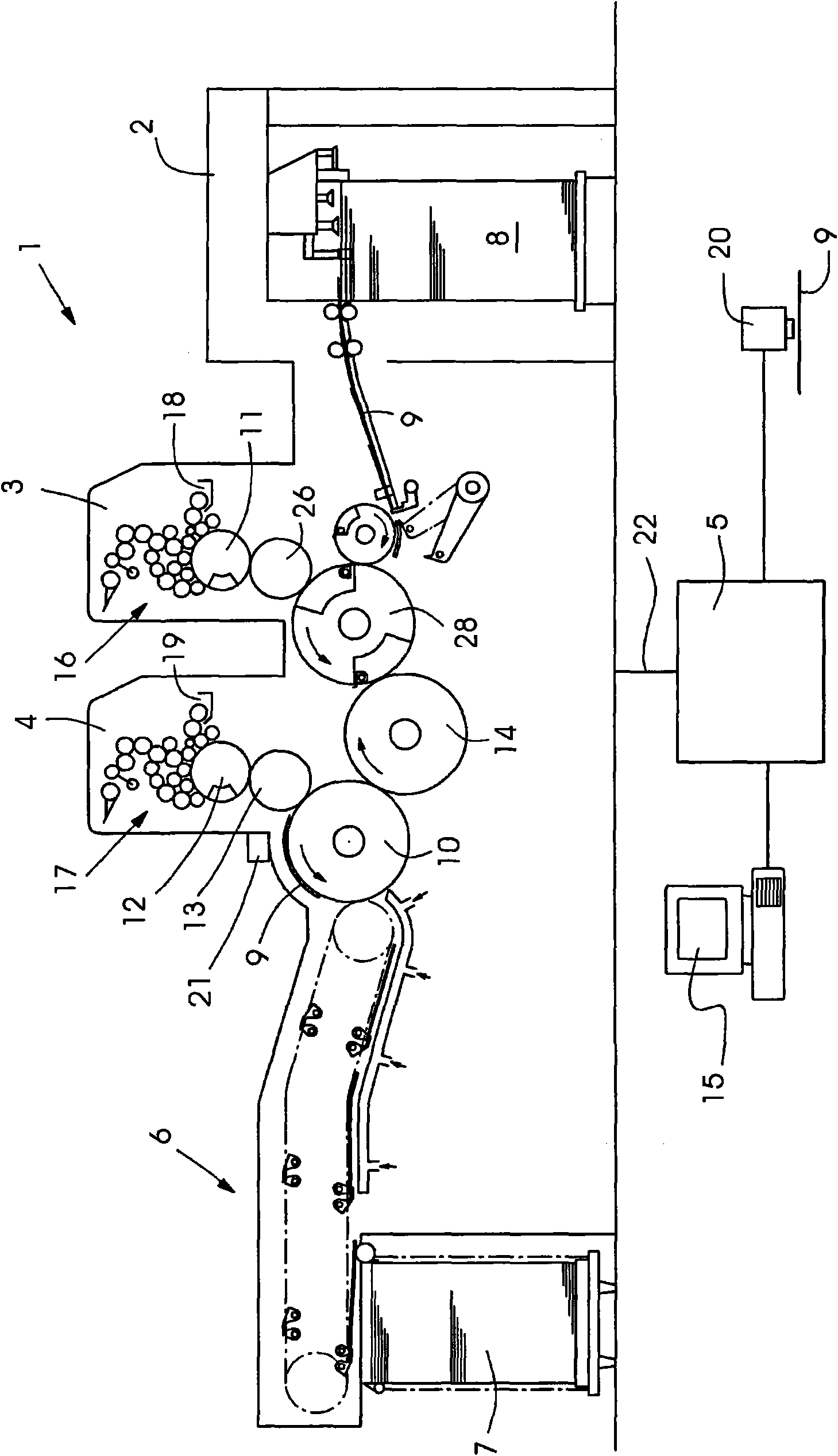

[0046] figure 1 A sheetfed offset printing press 1 is shown, which has, for example, two printing units 3 , 4 . Each of the two printing units 3 , 4 has an inking unit 16 , 17 and a dampening unit 18 , 19 . In the inking units 16 , 17 the printing ink is homogenized for printing over the entire width of the printing unit by means of a plurality of distribution rollers. Furthermore, dampening agent is delivered by means of dampening devices 18 , 19 in order to be able to apply a precise ink consistency to the printing plates of the printing plate cylinders 11 , 12 . The ink fountains of the two inking units 16 , 17 are each configured here as segmented ink fountains, the number of ink zones in the ink fountains being dependent on the size of the machine. A sheet-fed offset printing press 1 with a format of 70 cm x 102 cm typically has 64 ink zones. Printing ink is transferred from the plate cylinders 11 , 12 via the blanket cylinders 13 , 26 to the printing material 9 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com