Equipment containing medium cutting mechanism

A cutting mechanism and medium technology, applied in the direction of metal processing, etc., can solve the problems of low efficiency, troublesome cutting, low cutting quality, etc., and achieve the effect of simple operation, straight cutting seam and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1. In the device containing the medium cutting mechanism, the medium is placed on the medium supporting plate, and the supporting plate gap is set on the medium supporting plate. The medium cutting mechanism includes: a knife holder, a first blade, a first upper Pressing wheel set, the second upper pressing wheel set, the knife rest includes an upper crossbeam and two upper side limbs connected with the upper crossbeam, the first blade is installed on the upper crossbeam of the knife rest, and the The first upper pressure roller group and the second upper pressure roller group are respectively installed on the upper side limbs of the knife holder, straddle the two sides of the supporting plate gap, press the medium, and the supporting plate gap The width is greater than the thickness of the first blade.

[0013] The working principle of the medium cutting mechanism in the equipment is as follows: under the action of gravity, the two pressure wheel sets instal...

Embodiment 2

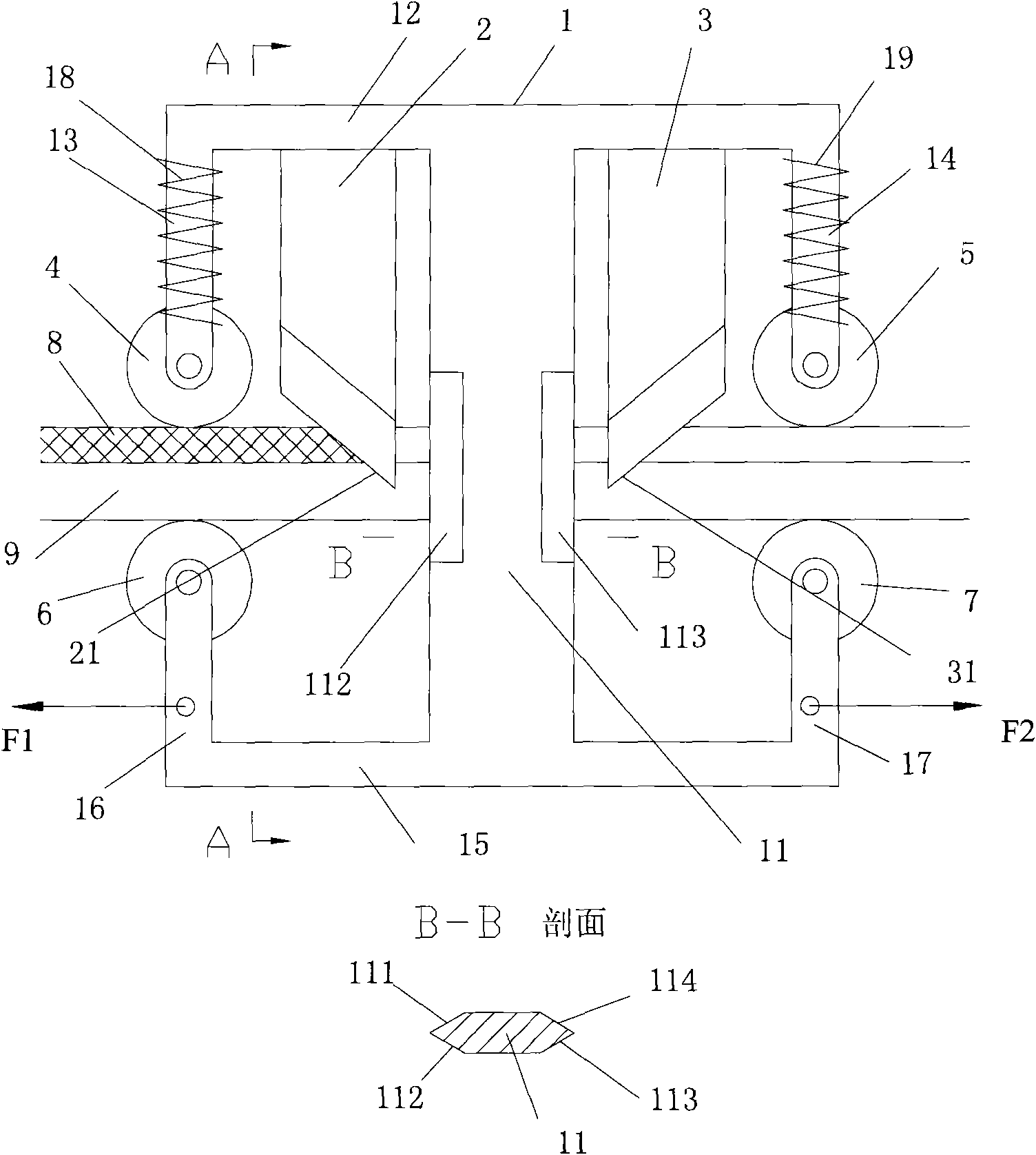

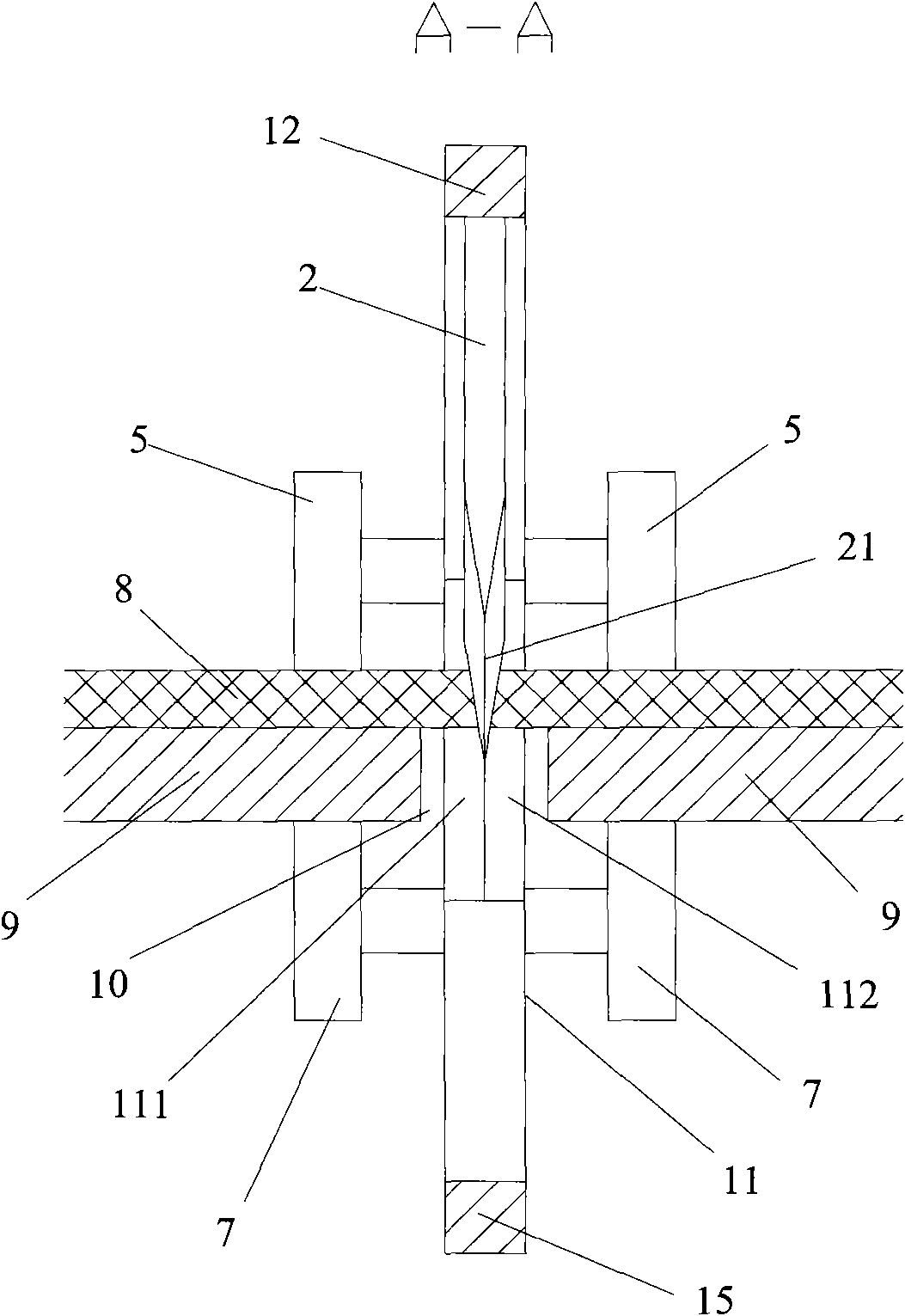

[0026] Embodiment two, figure 1 It is the front view of the medium cutting mechanism in the second embodiment of the present invention, figure 2 It is the medium cutting mechanism in the second embodiment of the present invention figure 1 In the sectional view of A-A, the media cutting mechanism includes: a knife holder 1 , a blade set formed by blades 2 and 3 , an upper pinch roller set 4 , an upper pinch roller set 5 , a lower pinch roller set 6 , and a lower pinch roller set 7 . The tool rest 1 is an I-shaped structure, including a column 11, an upper beam 12 connected with the upper end of the column, and upper side limbs 13 and 14 connected with the upper beam 12, a lower beam 15 connected with the lower end of the column, and a lower beam 15 connected with the lower beam 15. The lower limbs 16 and 17 are connected. The blades 2 and 3 are installed on the upper beam 12 of the tool holder 1 and are distributed on both sides of the column 11 . The upper pressing wheel g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com