Cutter frame mechanism for processing spherical surface roller

A technology of spherical roller processing and tool rest, which is applied in metal processing equipment and other directions, can solve problems such as waste and complicated cost of components, and achieve the effects of easy processing, good wear resistance, and simplified part of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

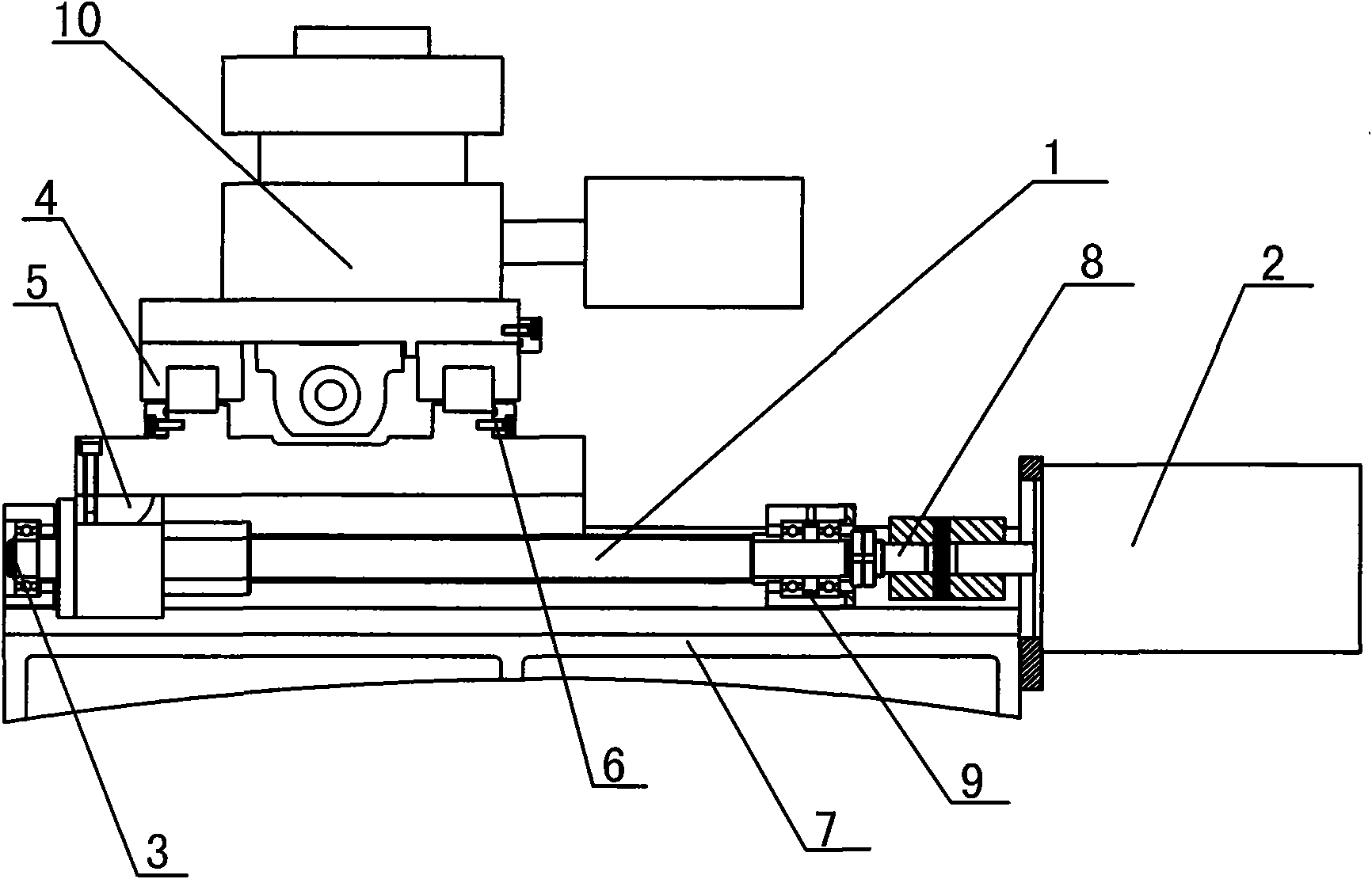

[0011] Such as figure 1 As shown, the tool holder mechanism for spherical roller processing according to the present invention includes a ball screw 1 and a rolling guide 4, the ball screw 1 is arranged on the upper side of the chassis 7, and one part of the ball screw 1 The drive unit 2 is connected to the side, and the linkage rod 8 is connected between the drive unit 2 and the ball screw 1, and the linkage rod 8 is connected with the transmission assembly 9; the other side of the ball screw 1 is provided with a stop Ring 3, the upper side of the ball screw 1 is provided with a rolling guide 4, the lower end of the rolling guide 4 is provided with a bolt 6, and the upper part of the rolling guide 4 is provided with a cutting unit 10; the upper side of the ball screw 1 Connect pin 5. The rolling guides are 4 linear sliding guides with good wear resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com