Yoghurt with active ingredients and heat-sensitive materials in cow milk being preserved and production method thereof

A technology of active ingredients and production method, which is applied in the field of yogurt that retains active ingredients and heat-sensitive substances in milk and its production field, and can solve the problems of loss of active ingredients and heat-sensitive substances, inactivation of functional substances, and reduction of yogurt health care function. , to achieve the effect of improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Method for producing stirred yogurt that retains active ingredients and heat-sensitive substances in milk by membrane filtration sterilization

[0056] formula:

[0057] ingredient name

Amount added%

Amount added (kg / ton)

milk

94.93

949.3kg

white sugar

4.95

49.5kg

Stabilizer FH9CMC

0.12

1.2kg

40U

40U

WPC80 whey powder

0

0kg

[0058] Raw material standard:

[0059] Milk: in line with the various project indicators of GB / T 6914-1986 "Standards for Purchasing Fresh Milk";

[0060] White sugar, stabilizer, dry powder bacteria, WPC80 whey powder meet the relevant national standards;

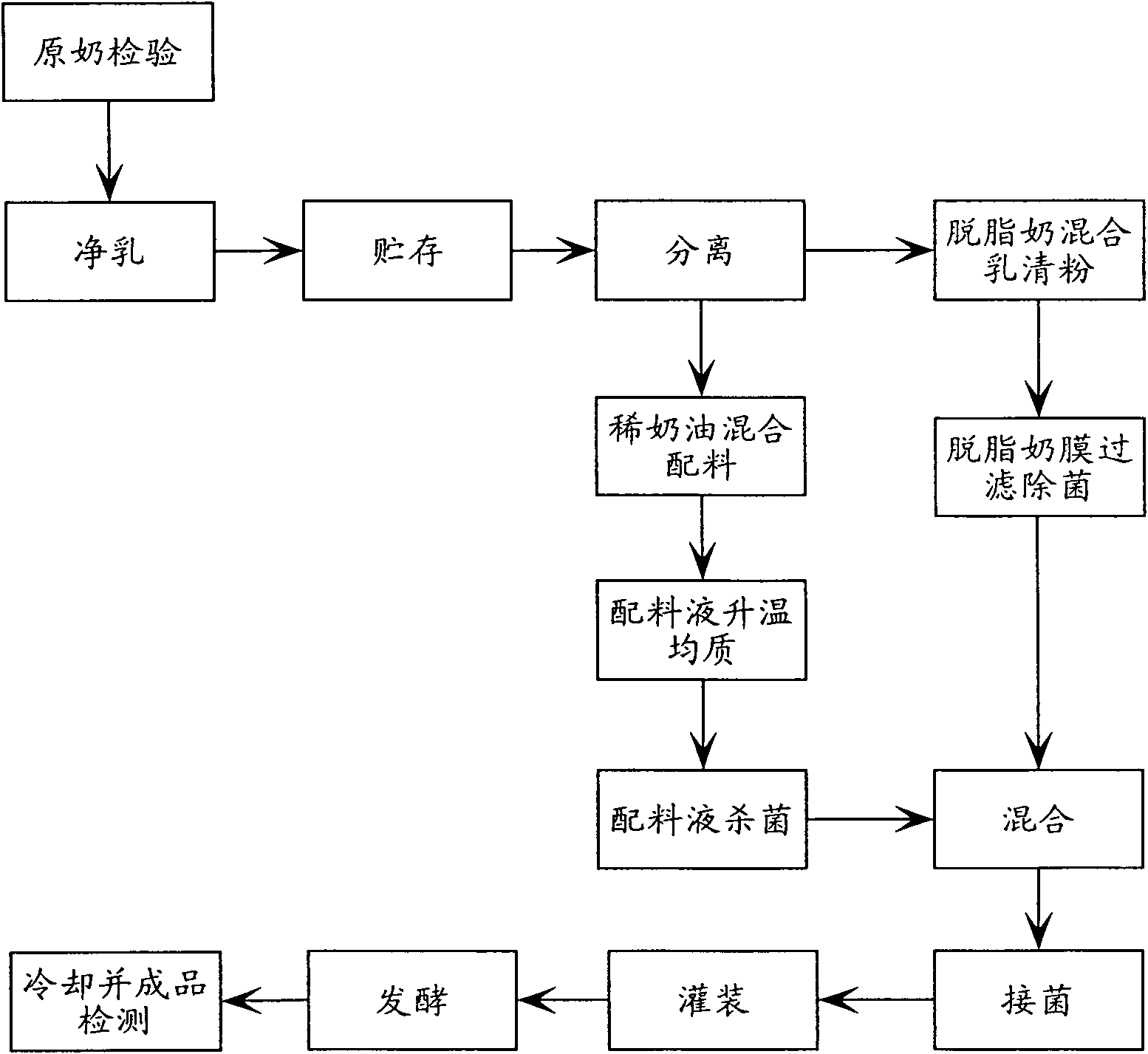

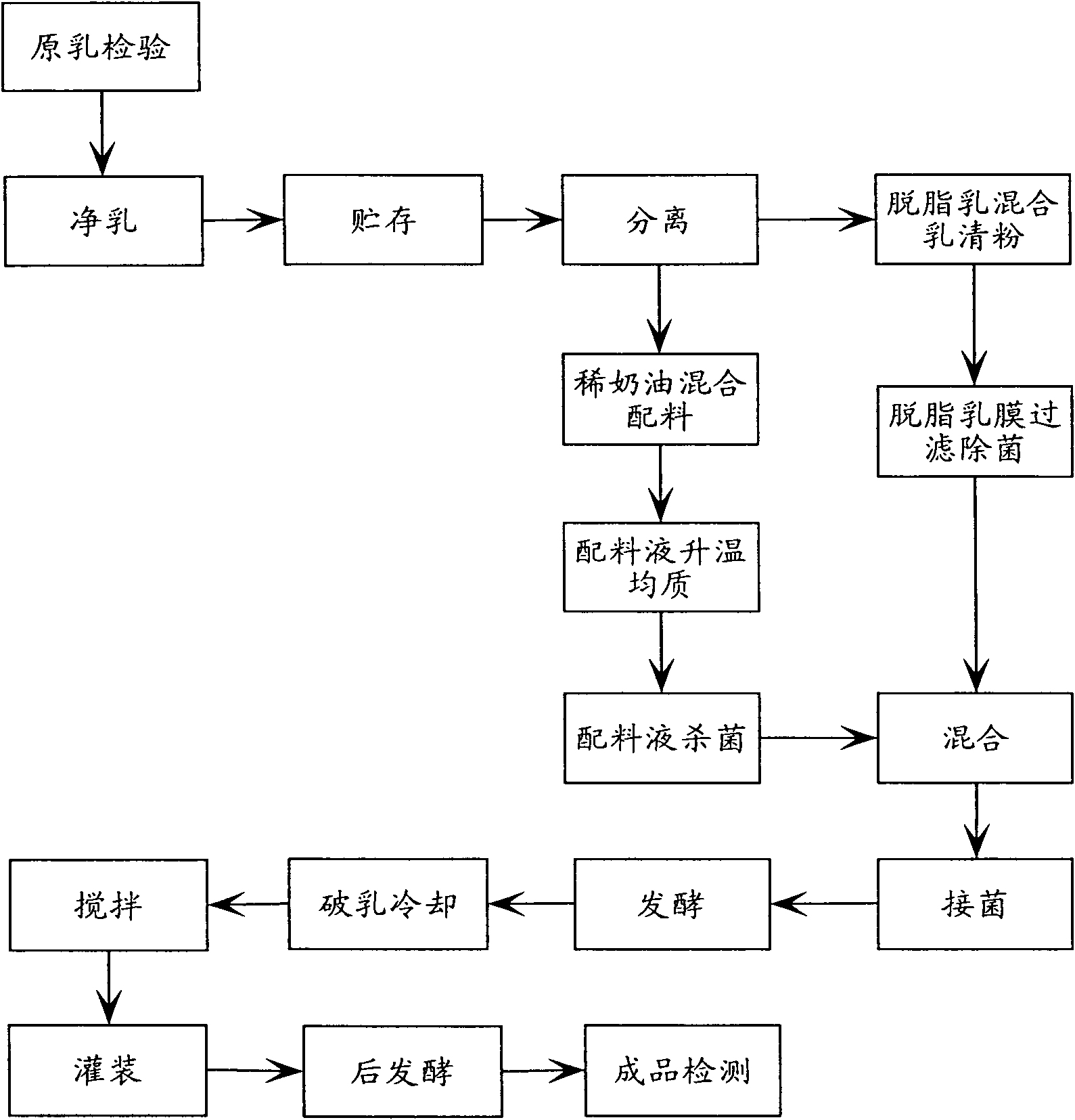

[0061] According to the invention, the stirred yoghurt presses the membrane filter to sterilize and retain active ingredients and heat-sensitive substances in milk. figure 2 The shown process route is produced, and the preparation process is as follow...

Embodiment 2

[0080] Example 2: Method for producing stirred yogurt that retains active ingredients and heat-sensitive substances in milk by membrane filtration sterilization

[0081] formula:

[0082] ingredient name

Amount added%

Amount added (kg / ton)

milk

86.95

869.5kg

white sugar

12

120kg

FH9CMC

0.05

0.5kg

100U

100U

WPC80 whey powder

1.0

10kg

[0083] Raw material standard: with embodiment 1.

[0084] According to the invention, the stirred yoghurt presses the membrane filter to sterilize and retain active ingredients and heat-sensitive substances in milk. figure 2 Shown process is produced, and preparation process is as follows:

[0085] Raw milk inspection: with embodiment 1.

[0086] Clean milk: Use a high-speed centrifugal separator at 3000rpm at 30°C for 0.02 seconds to remove impurities from the raw milk so that the impurity level is ≤2PPM;

[008...

Embodiment 3

[0103] Example 3: Method for producing stirred yogurt that retains active ingredients and heat-sensitive substances in milk by membrane filtration sterilization

[0104] formula:

[0105] ingredient name

Amount added%

Amount added (kg / ton)

milk

91.42

914.2kg

white sugar

8

80kg

FH9CMC

0.08

0.8kg

WPC80 whey powder

0.5

5kg

Dry powder bacteria

70U

70U

[0106] Raw material standard: with embodiment 1.

[0107]According to the invention, the stirred yoghurt presses the membrane filter to sterilize and retain active ingredients and heat-sensitive substances in milk. figure 2 The shown process route is produced, and the preparation process is as follows:

[0108] Raw milk inspection: with embodiment 1;

[0109] Clean milk: Use a high-speed centrifugal separator at 5600rpm at 20°C for a centrifugation time of 0.02 seconds to remove impurities from the raw milk so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com