Sorption pump with integrated thermal switch

An adsorption pump and adsorption material technology, which can be applied to liquid variable capacity machinery, pumps, instruments, etc., can solve the problems of increasing the length of the heat transfer path of the refrigerator and the adsorption pump, increasing the complexity of the system, and increasing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

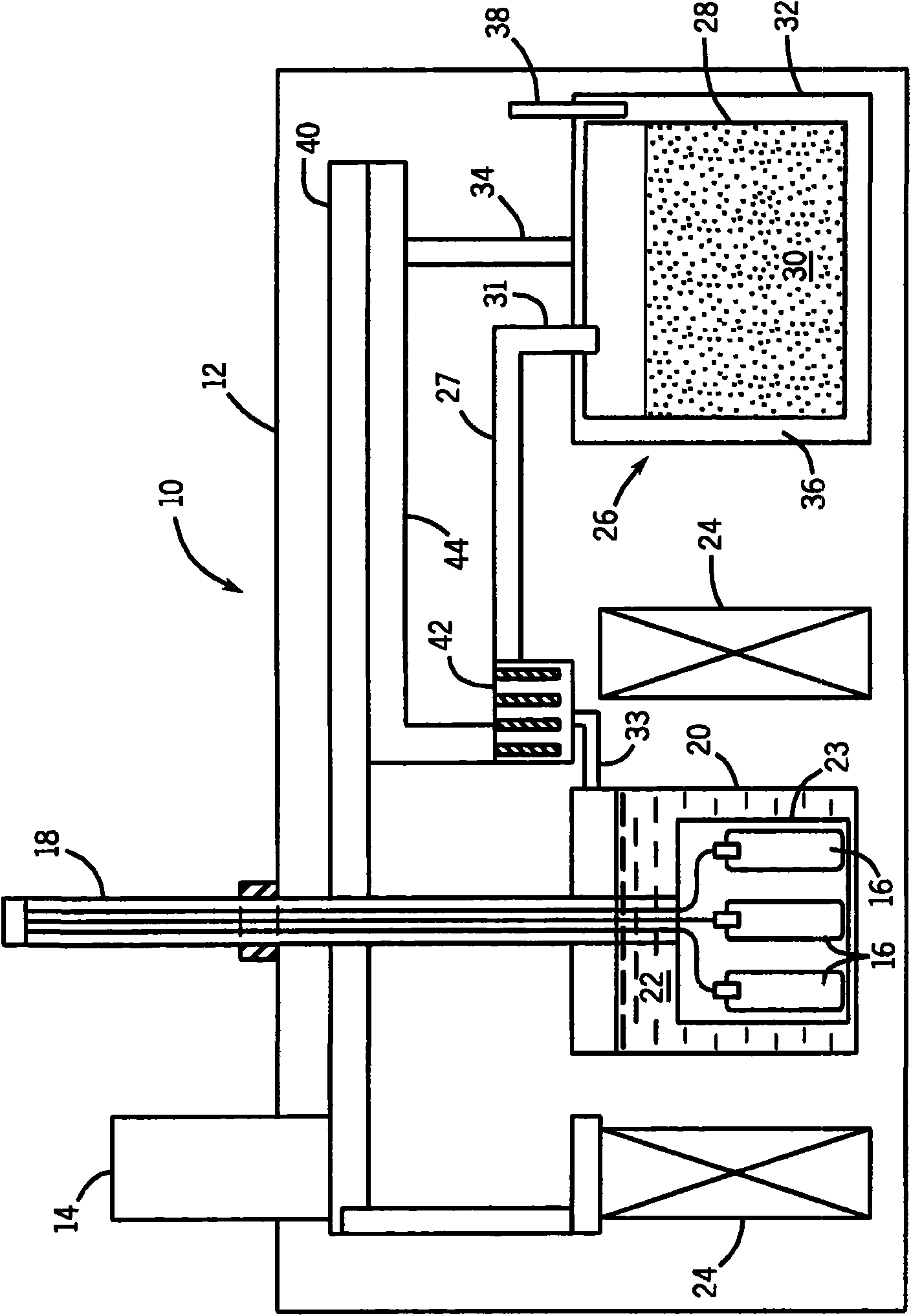

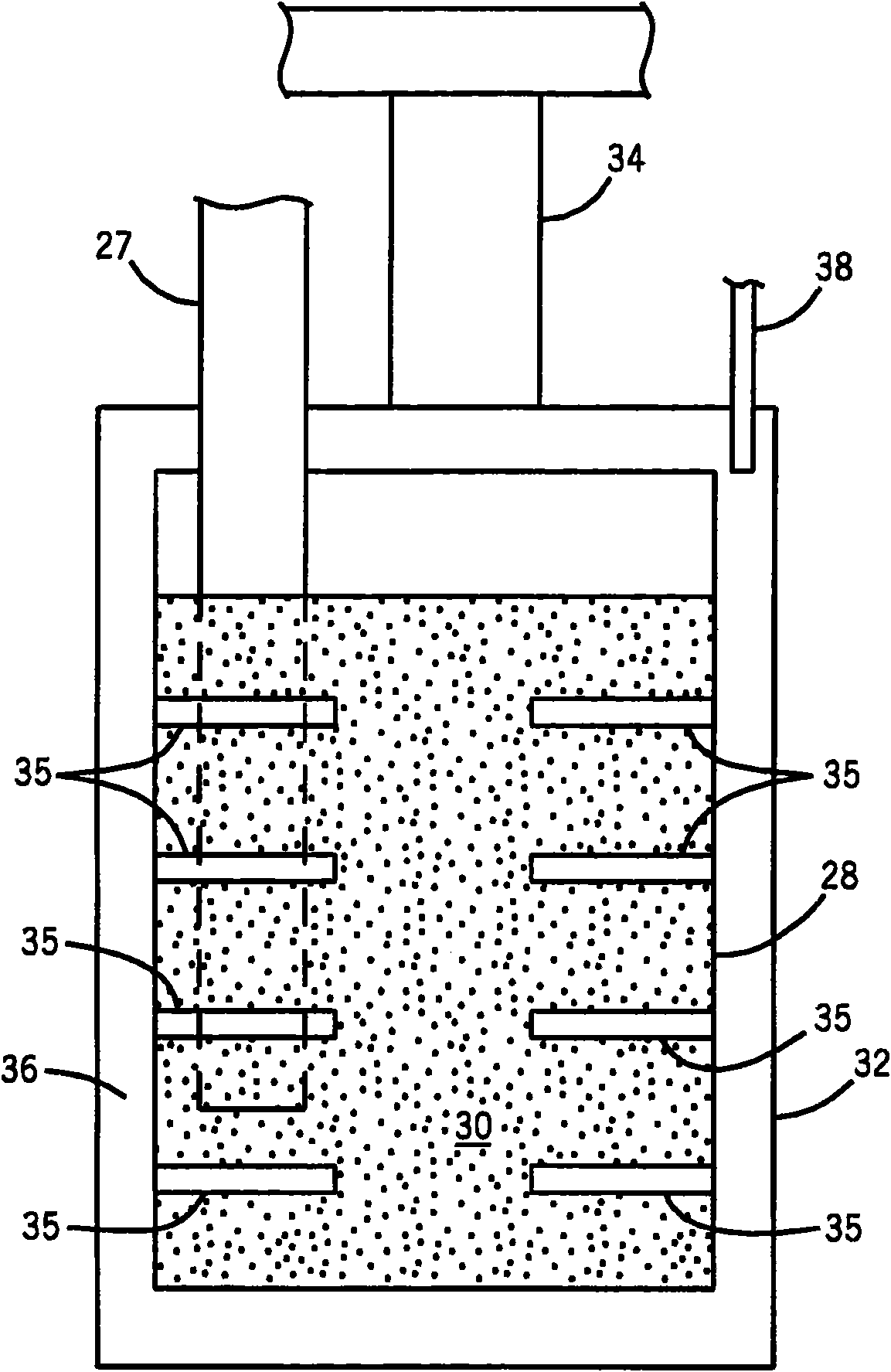

[0016] See attached figure 1 , where one embodiment of a sorption pump system 10 is shown. The sorbent pump system 10 is a closed cycle thermal system configured to hyperpolarize an imaging agent sample for use in magnetic resonance imaging (MRI). For example, samples can be obtained by 13 C 1 -pyruvate ( 13 C 1 -Pyruvate) or another similar metabolic imaging agent that can be polarized. The sorption pumping system 10 is formed in part by a vacuum chamber 12 which encloses the internal components of the system. A refrigerator 14 is also included as a cooling system for the system. In one embodiment, the refrigerator is a closed cycle refrigerator capable of providing a low temperature environment below 10K. as attached figure 1 As shown, the refrigerator 14 is disposed at least partially outside the vacuum chamber 12 . Such a structure enables any heat generated by the refrigerator 14 to be discharged to the external environment without being discharged to the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com