Pressure control butterfly valve

一种压力控制、蝶式的技术,应用在压力控制领域,能够解决真空配管5安装空间变大、构造复杂等问题,达到优异防漏性能、安装宽度减小、高速且高精度压力控制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

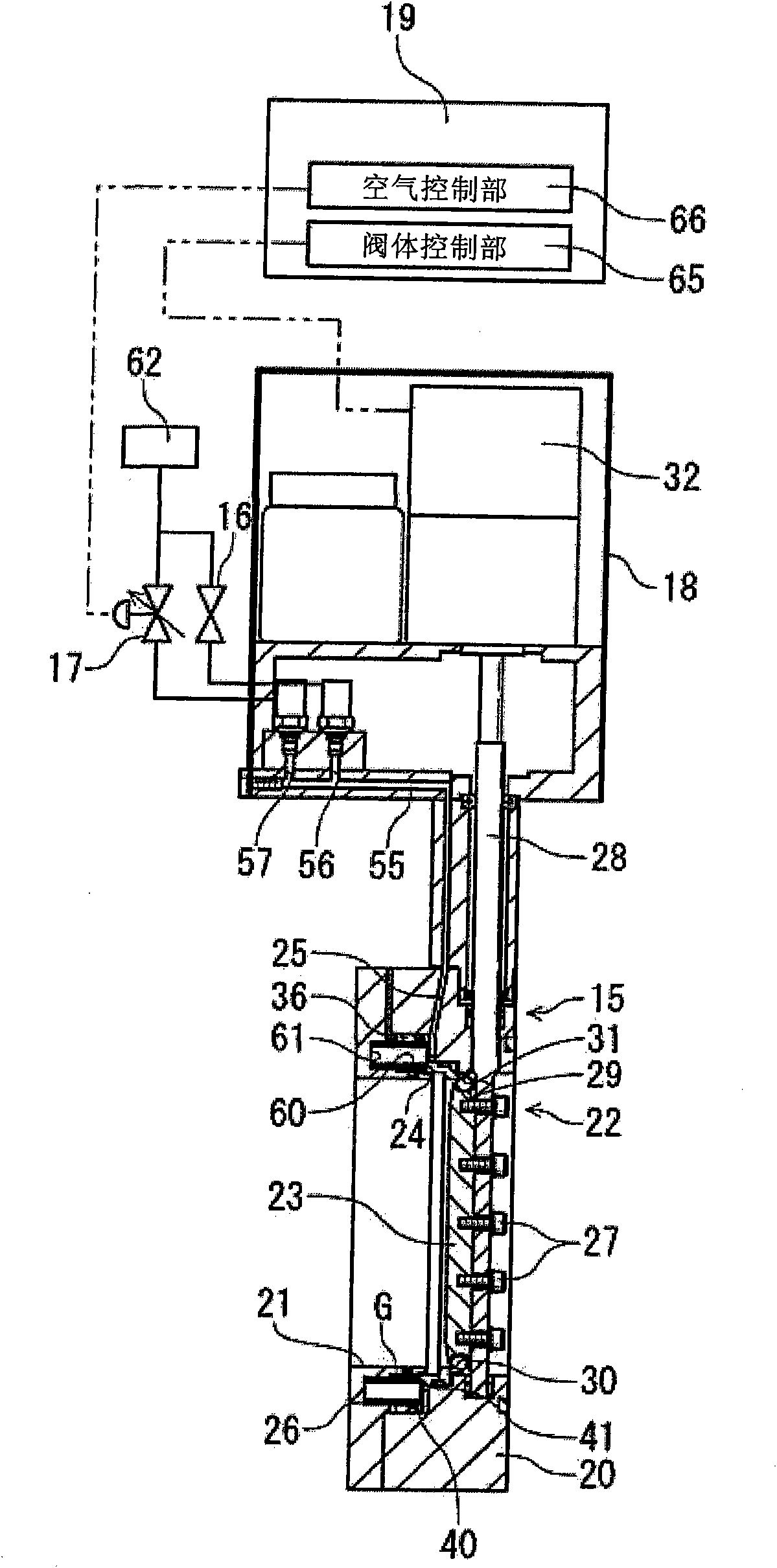

[0080] Hereinafter, a preferred embodiment of the butterfly pressure control valve of the present invention will be described in detail with reference to the accompanying drawings. Such as Picture 10 As shown, for example, in the pipeline 10 in the semiconductor manufacturing process, the butterfly pressure control valve of the present invention is connected between the vacuum chamber 11 and the vacuum pump 12, and includes a valve body 15 and a solenoid valve 16 connected to the valve body 15 , Electro-pneumatic regulator 17, actuator 18 and controller 19.

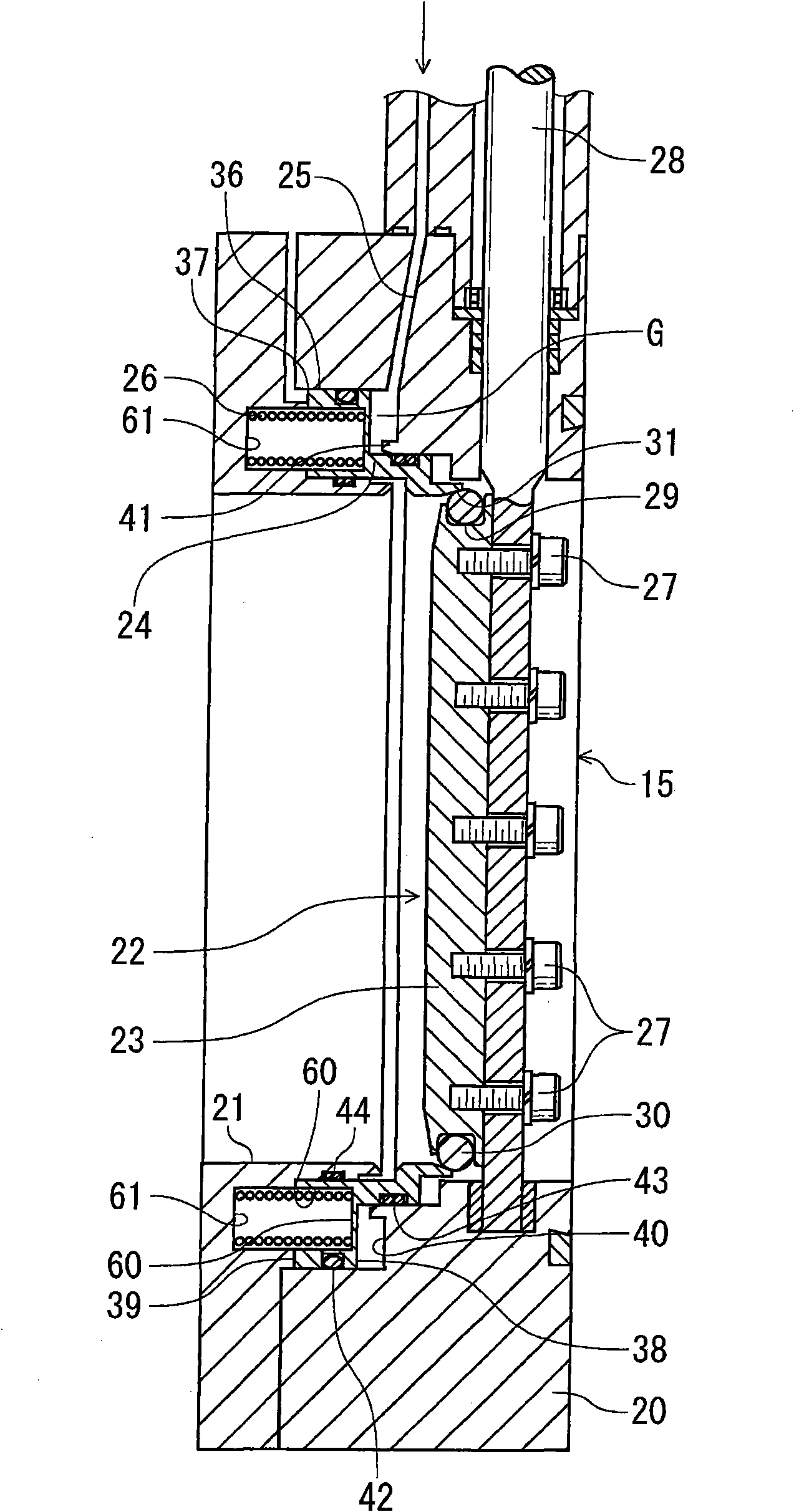

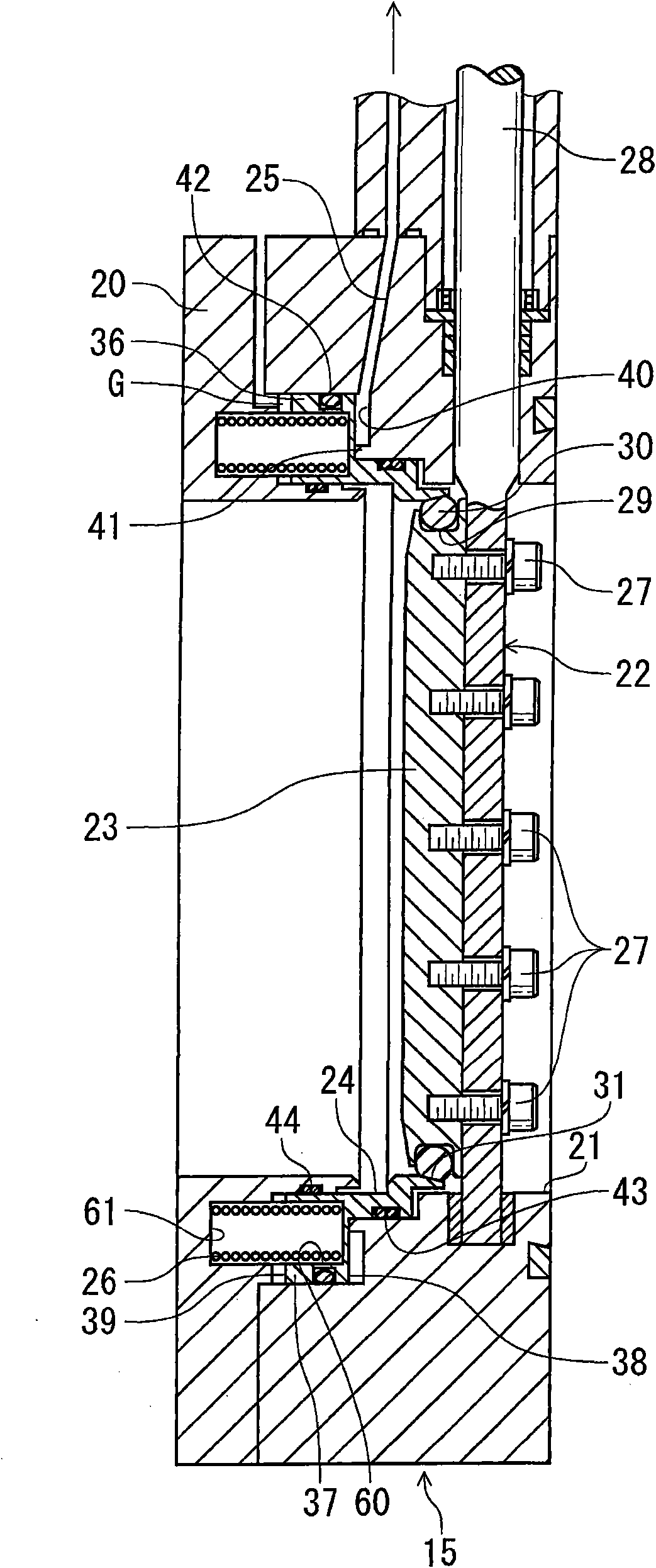

[0081] in figure 1 Here, one embodiment of the butterfly pressure control valve of the present invention is shown. A flow path 21 is formed in the main body 20 of the valve main body 15, and a valve opening and closing mechanism 22 that opens and closes the flow path 21 is provided. The valve opening and closing mechanism 22 has a valve body 23, a seat ring 24, an air flow path 25 and a spring 26.

[0082] In the valve op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com