Chassis component for a motor vehicle

A component and body technology, applied in the field of body components, can solve the problems of not helping the absorption capacity, not helping to strengthen the body, etc., and achieve the effect of high ductility and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

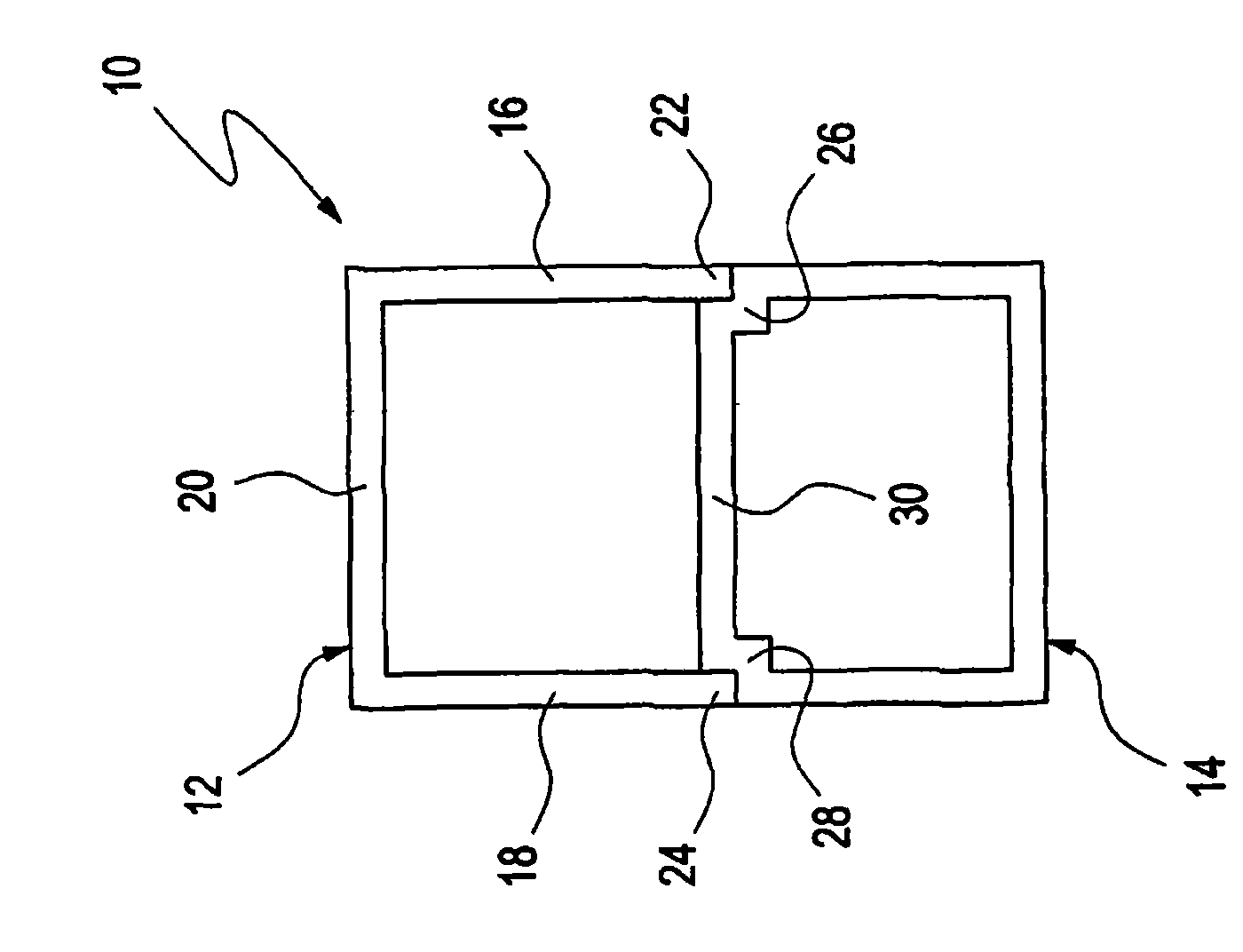

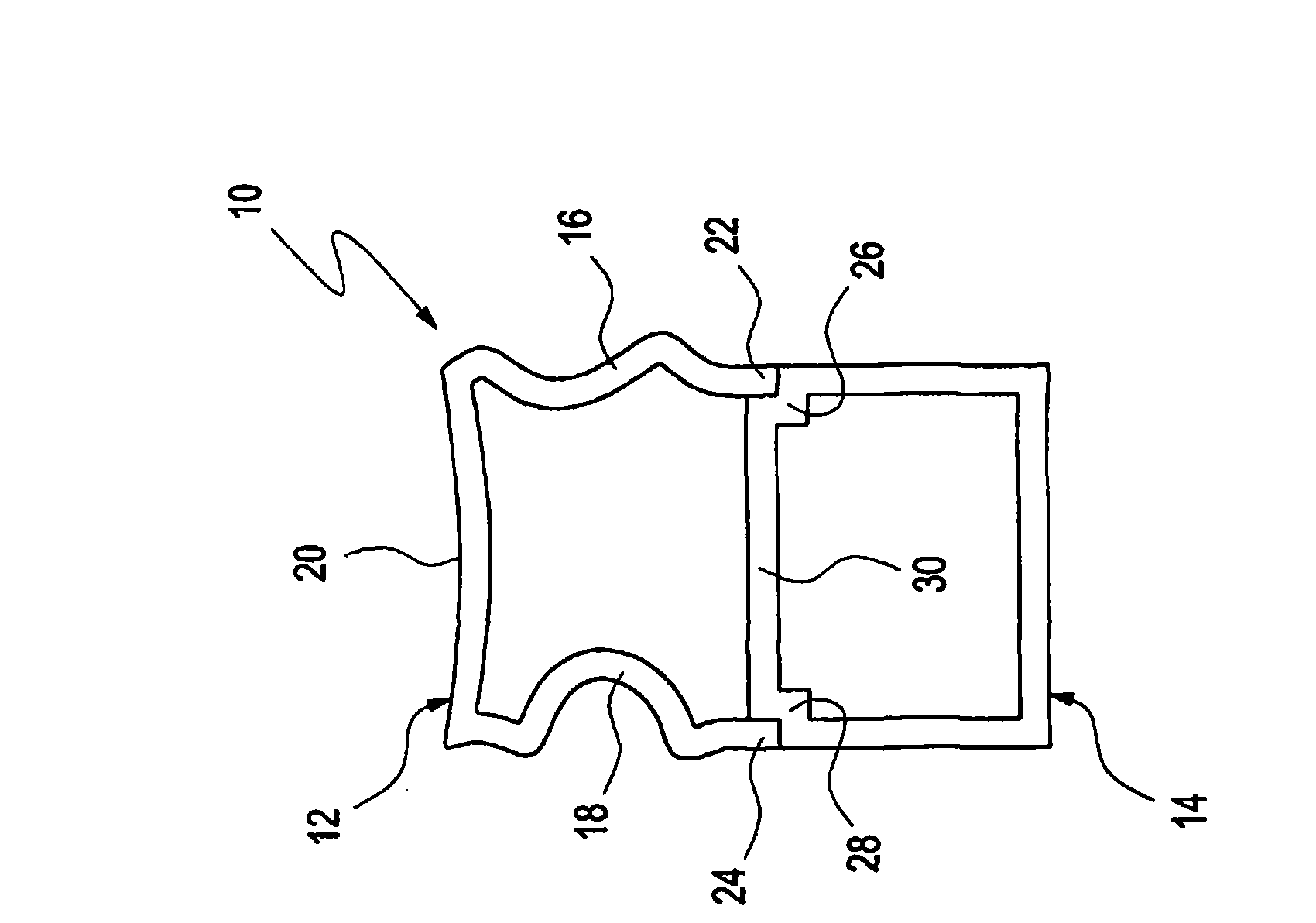

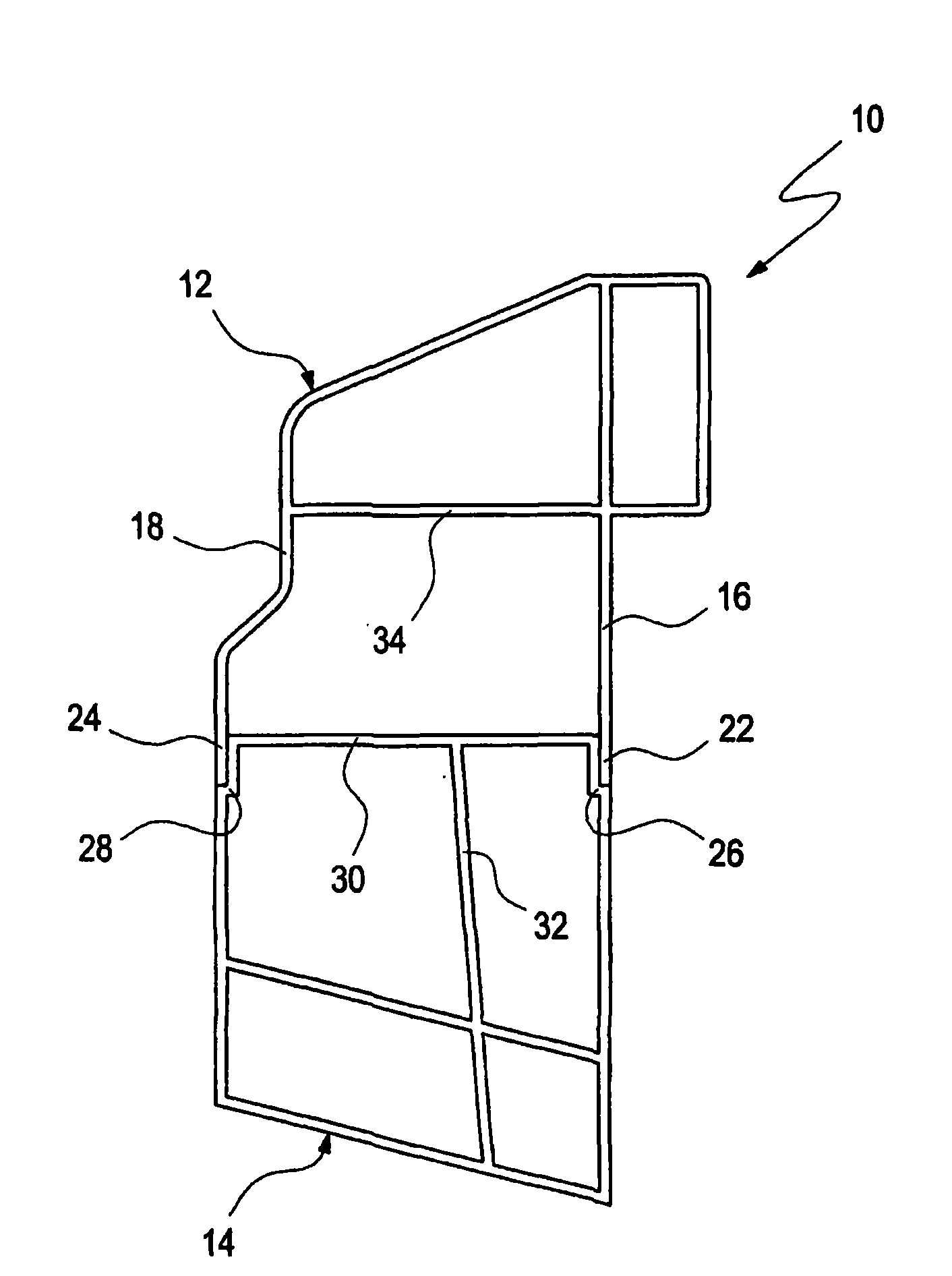

[0018] exist Figure 1a and 1b In the schematic sectional view, a body component in the form of a door pillar 10 , for example a B-pillar, is shown. Figure 1a The doorpost 10 is shown in an undeformed state, as will also be explained in detail, in Figure 1b The door pillar 10 is shown after a force application caused by an accident, for example due to a side impact of a car.

[0019] The door pillar 10 here comprises a first outer individual component 12 and an inner second individual component 14 . In other words, the individual component 12 faces mainly towards the outside of the motor vehicle, and the individual component 14 faces towards the passenger compartment of the motor vehicle, not otherwise shown.

[0020] Depend on Figure 1a It can be seen that the first individual component 12 is substantially U-shaped and comprises two free arms 16 , 18 which are integrally connected to each other by a connecting arm 20 . The outer individual component 12 can here be produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com