Detection method of armature stamping trough position degree

A technology of armature punching and detection method, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of scrapped iron core, uneven groove shape, etc. Effect

Inactive Publication Date: 2010-12-01

CRRC YONGJI ELECTRIC CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to find out whether the position degree of the groove shape of the punching sheet is qualified in time in the process of punching the sheet with the processing technology of the single punching groove die, the invention avoids that the position degree of the groove shape of the punching sheet is found to be out of tolerance when the iron core is stacked, which causes the iron core to be stacked. The groove shape is not uniform after pressing, which causes the core to be scrapped. A method for detecting the position degree of the armature punching piece groove shape is provided.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

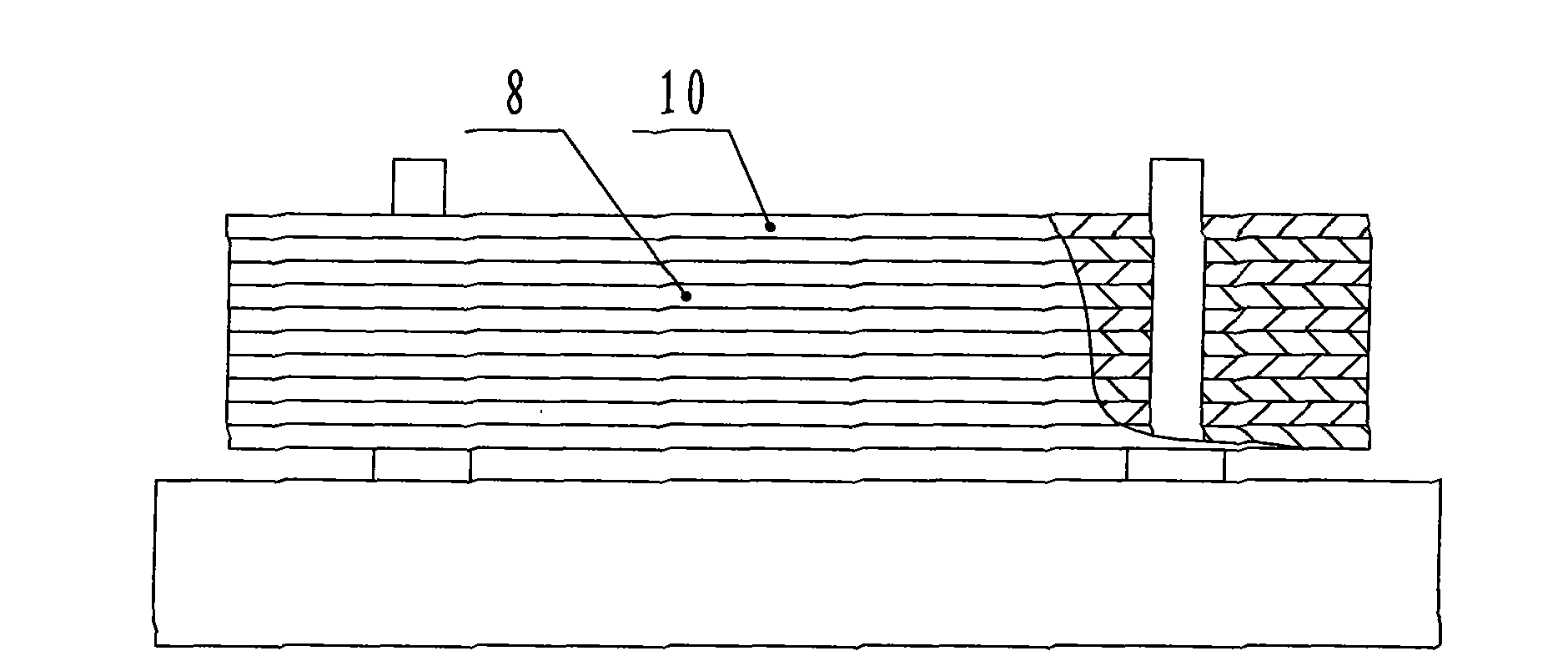

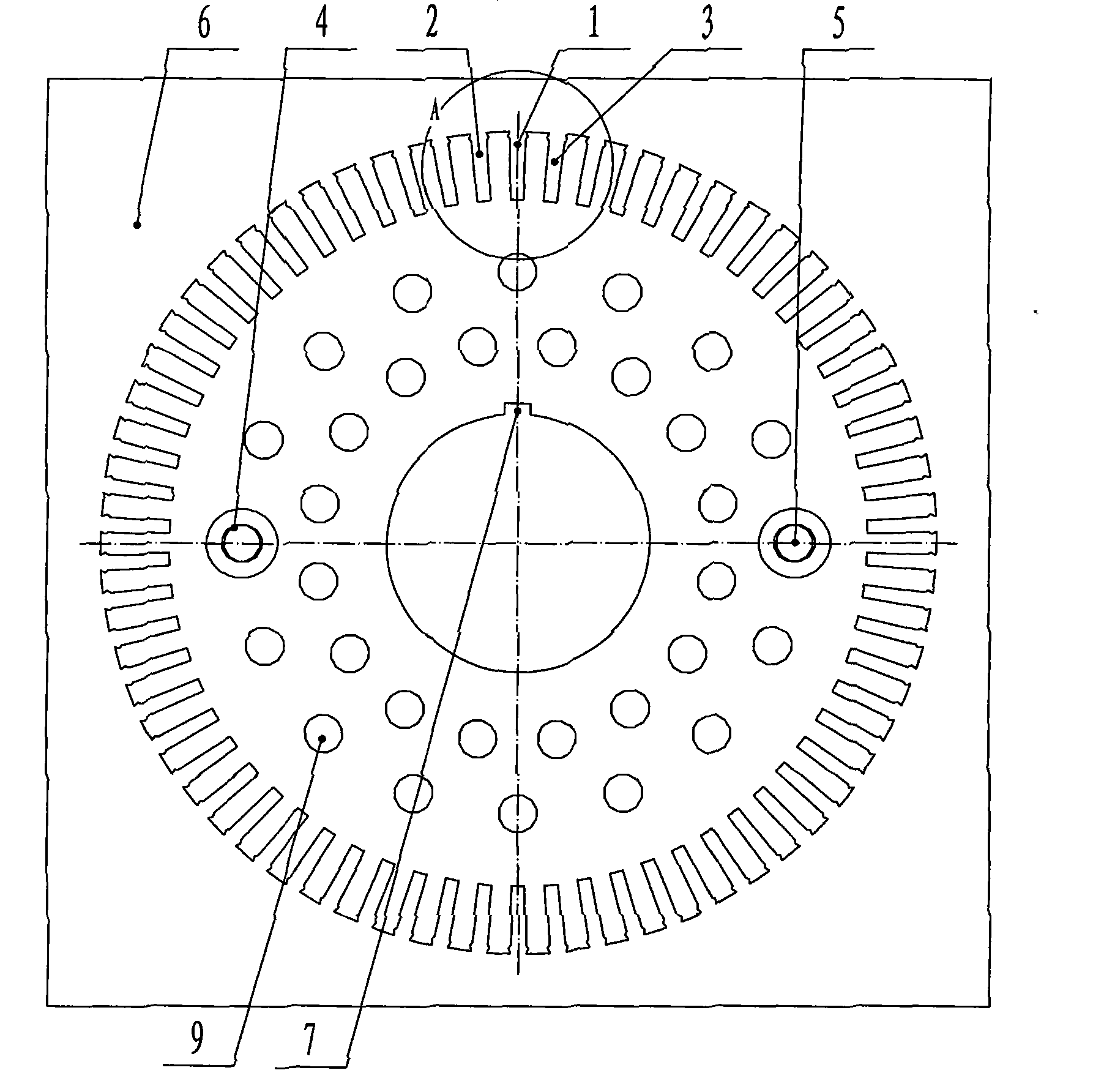

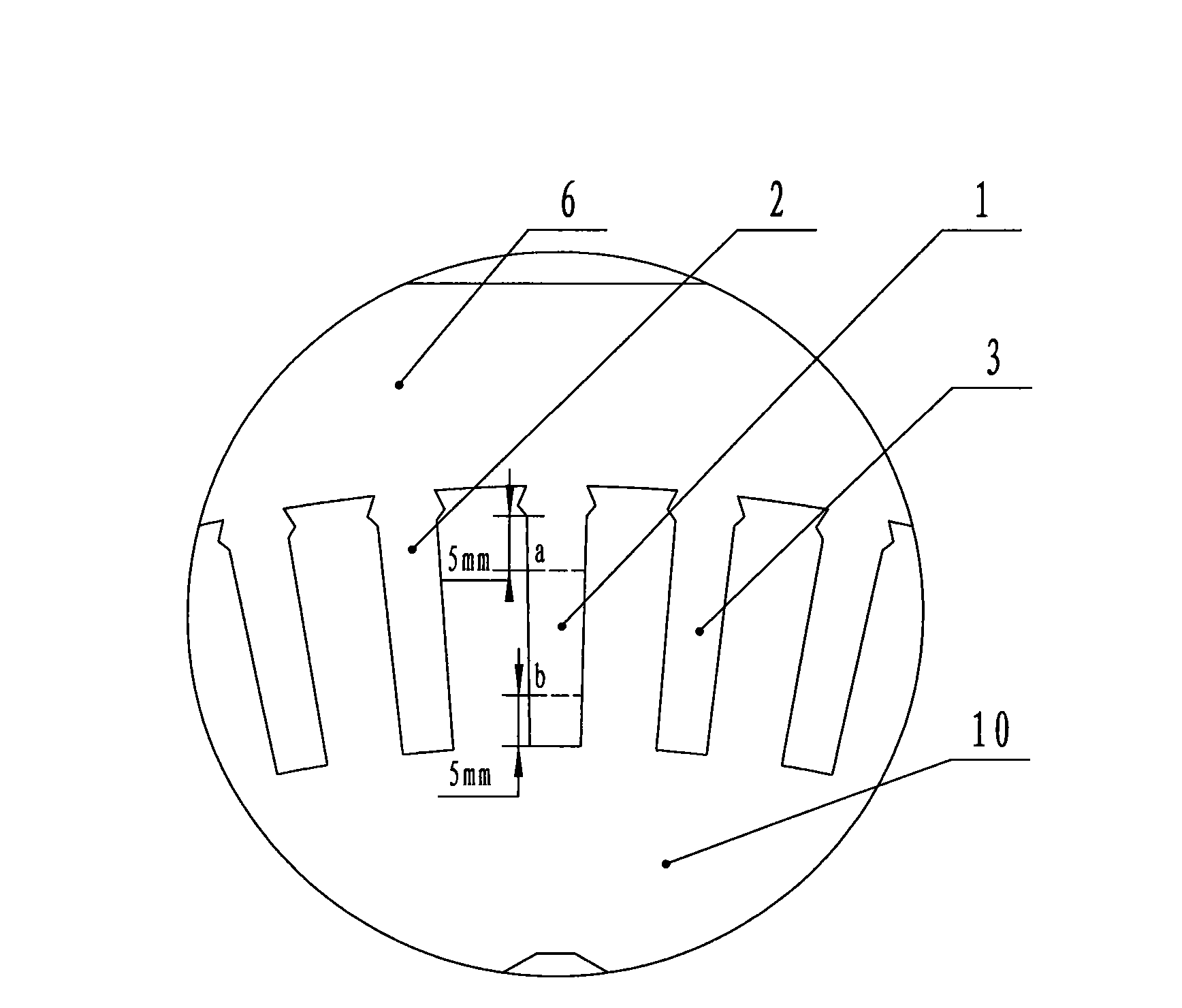

The invention relates to the field of manufacture of motors, in particular to a detection method of armature stamping trough position degree. The detection method can find whether the stamping trough position degree is qualified or not in time during the stamping process of a single stamped trough, and the steps are as follows: 1, detecting the first stamping by three coordinates after mounting amold, if qualified, stamping a plurality of stampings; 2, measuring the size of a stamping trough which is positioned on the same central line of a stamping key slot on the first stamping and the adjacent two troughs; 3, keeping big head ends of two positioning pins downward, laying flat on a platform, overlapping the stampings, placing on the platform, and keeping that the two positioning pins are inserted in two symmetric vent holes on the stampings; 4, measuring the overall trough dimension of the overlapped stampings, if the dimension is totally smaller than or equal to the sum of the minimum trough dimension in the dimensions and the tolerance of the position degree stipulated by stamping processing drawings, and then stamping trough position degree is qualified; and 5, sampling stamping finished products, placing on the overlapped stampings and detecting whether the stamping trough position degree of the stamping finished products is qualified or not according to step 4. The detection is accurate, highly reliable, rapid, convenient, low in cost and high in efficiency.

Description

The detection method of the groove shape position degree of the armature punching piece technical field The invention relates to the field of motor manufacturing, in particular to a detection method for the groove shape position degree of an armature punching piece. Background technique Up to now, in the motor manufacturing industry, the groove shape of the motor armature punching generally adopts double punching groove (all groove shapes are punched out at one time) and single punching groove (all groove shapes are punched out sequentially on a single groove machine). A process plan for mold processing. Among them, after laminating the iron core, the punching sheet punched by the double punching method has a uniform groove shape, but the manufacturing cycle of the double punching die is long and the cost is high; therefore, single punching is usually used in production. Machine-punched stator and rotor punching groove shape, but due to factors such as the error of the tr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B5/00

Inventor 邱希赞田爱玲

Owner CRRC YONGJI ELECTRIC CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com