Driving circuit of high-voltage current transformer

A drive circuit and converter technology, applied in the field of high-voltage converters, can solve problems such as no successful cases and no literature reports, and achieve accurate and reliable drive functions, good economic and social benefits, flexible and adjustable IGBT overcurrent and The effect of short circuit protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

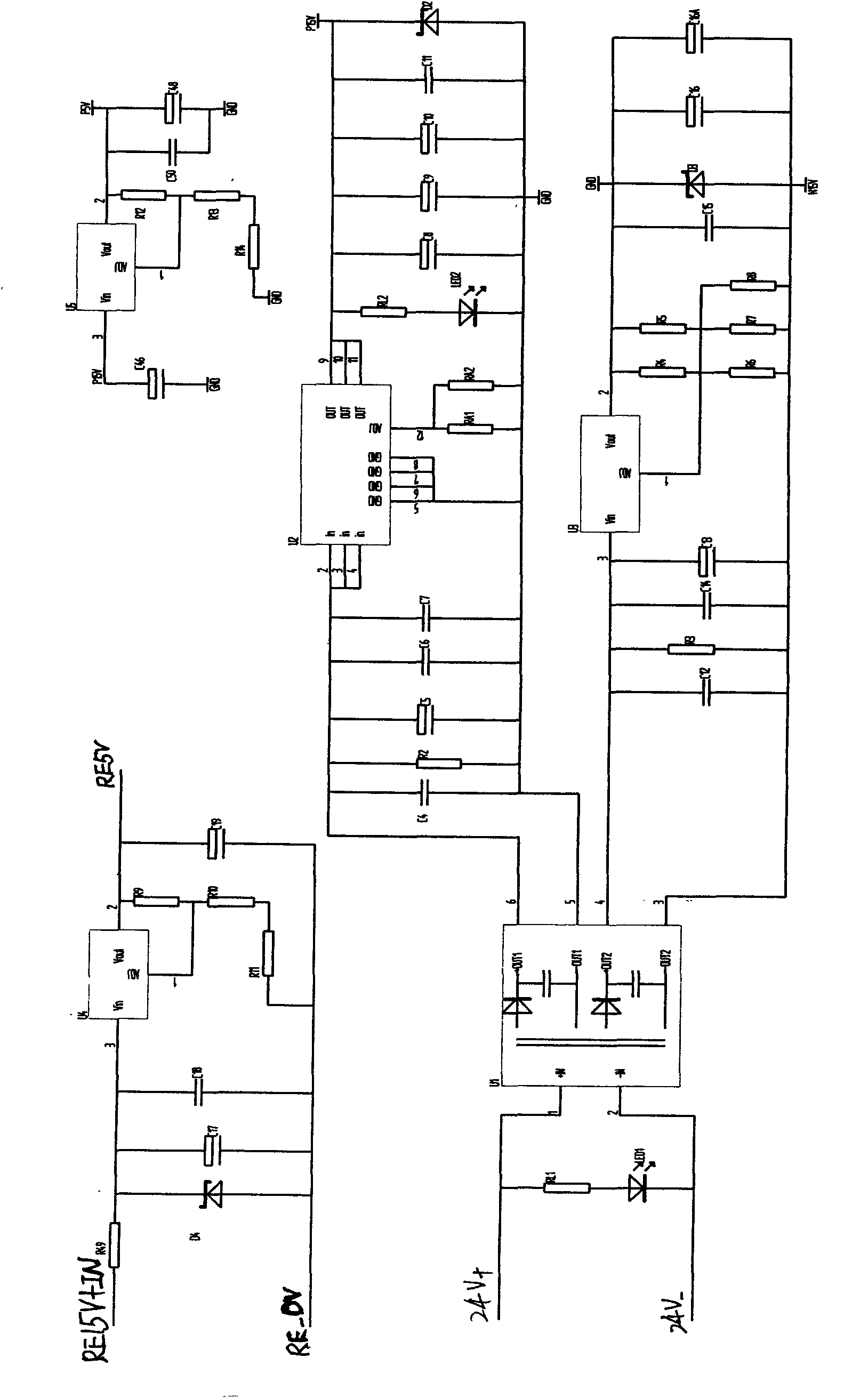

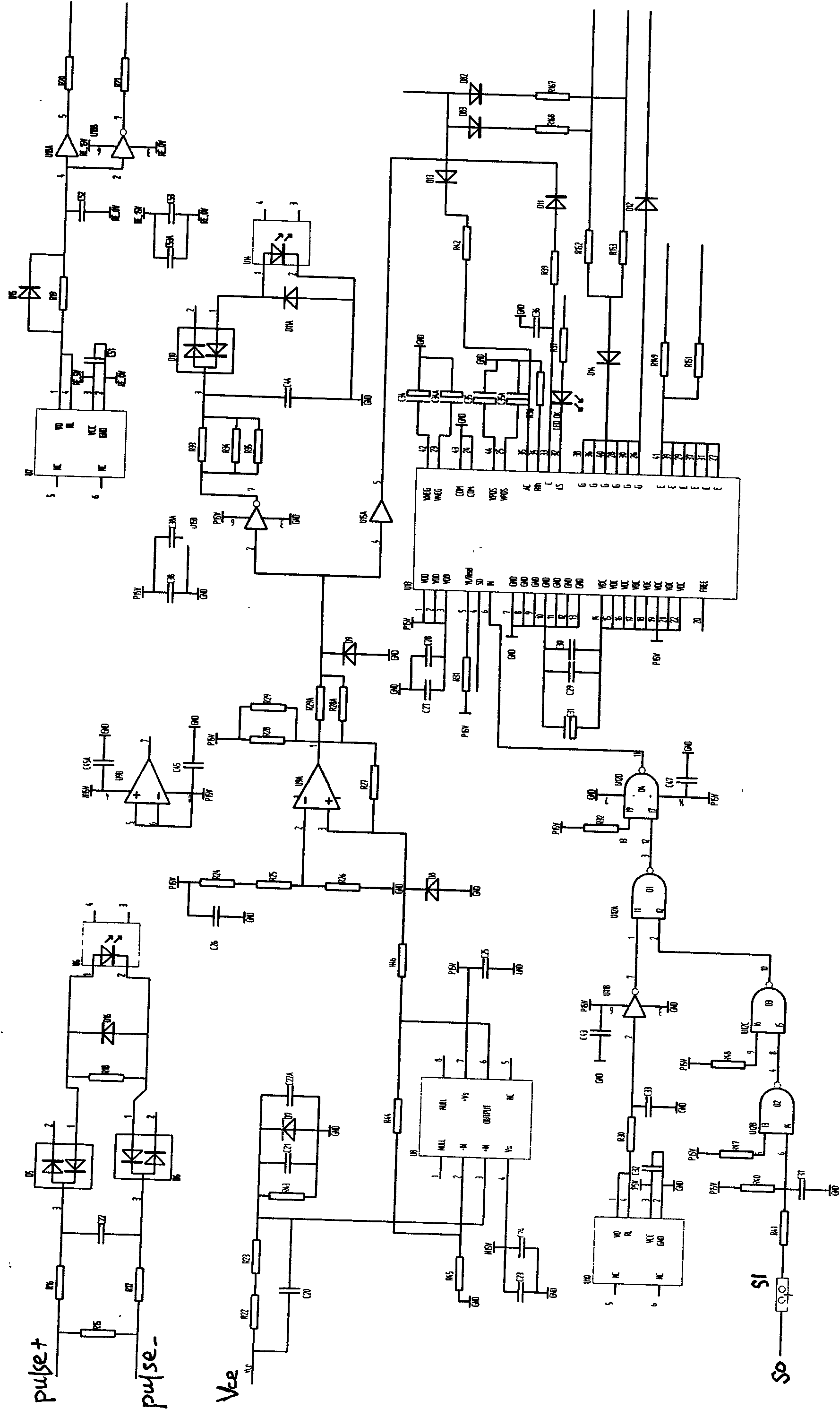

[0009] The driving circuit of the high-voltage converter includes a driving circuit, a power circuit, and a protection circuit. The power circuit includes a high-voltage isolation chip U1, the input terminal of the high-voltage isolation chip U1 is connected to the 24VDC input power supply, and the output terminal of the high-voltage isolation chip U1 A +15V power supply circuit containing a switching power supply chip U2 and a -15V power supply circuit containing an adjustable voltage regulator (device) chip U3 are connected. The +5V power supply circuit of the chip U4 and the +5V power supply circuit containing the adjustable voltage regulator chip U5 whose input terminal is connected to the output power supply terminal of the +15V power supply circuit; The input end is connected with a trigger pulse receiving circuit, the trigger pulse receiving circuit includes a first optical fiber transmitter U6 and a first optical fiber receiver U10, the output end of the first optical f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com