Hybrid transmission sensor web in coal mine

A hybrid transmission and sensor network technology, applied in the field of information transmission sensor network, can solve the problems of limiting the application range of wireless sensor network, the difficulty of wired connection, and the limitation of radio wave propagation, etc., to achieve good networking flexibility, low power consumption, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

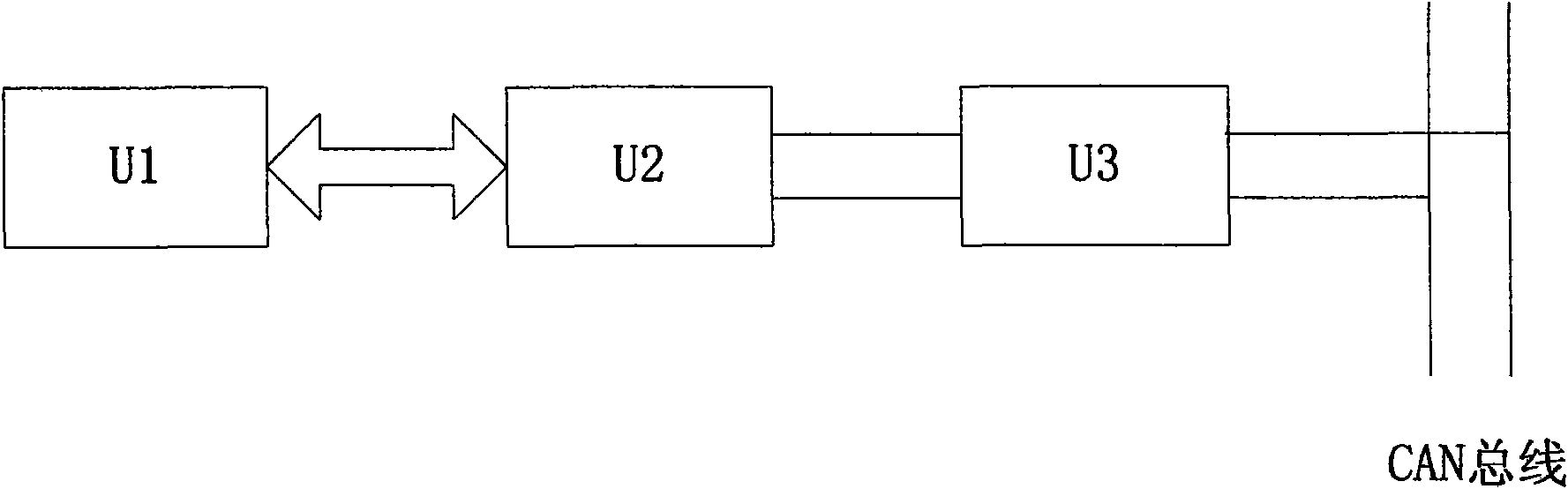

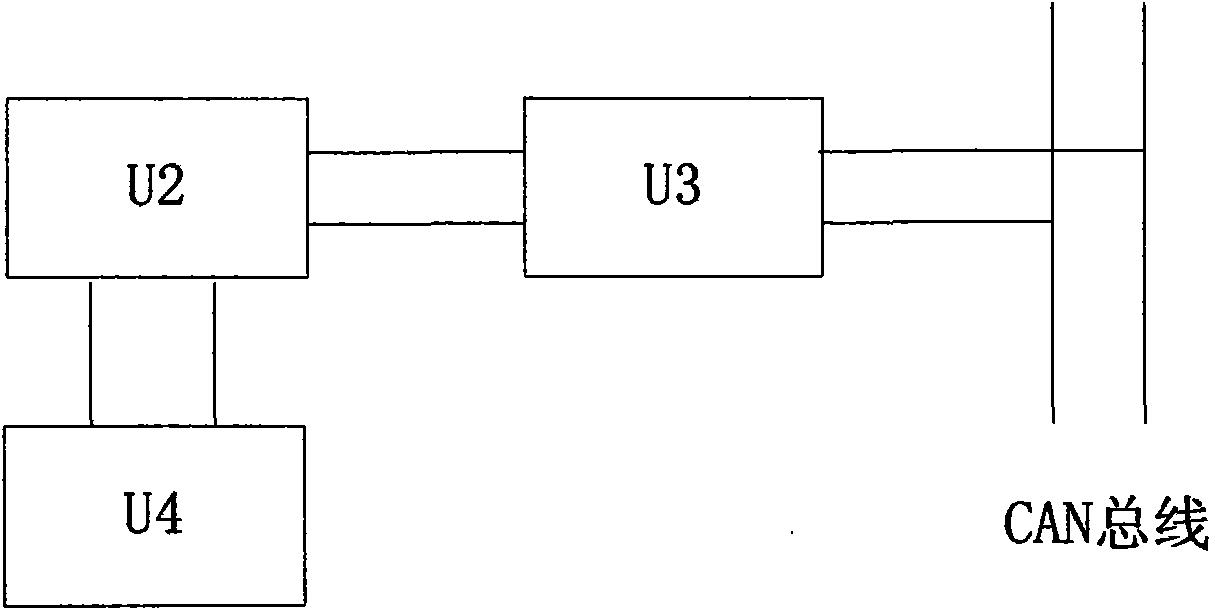

[0018] The wireless sensor node is composed of a wireless transceiver module, a microcontroller module and a sensor signal connector connected to the sensor; the conversion node is composed of a wireless transceiver module, a microcontroller module and connected to the CAN bus CAN transceiver modules are sequentially connected to form; the wired sensor node is composed of a microcontroller module, a CAN transceiver module and a sensor signal connector sequentially connected; the microcontroller model used by the wireless transceiver module is CC2420, and The microcontroller model used by the transceiver module is PIC18F2580, and the CAN driver model used by the CAN transceiver module is SN65HVD232.

[0019] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

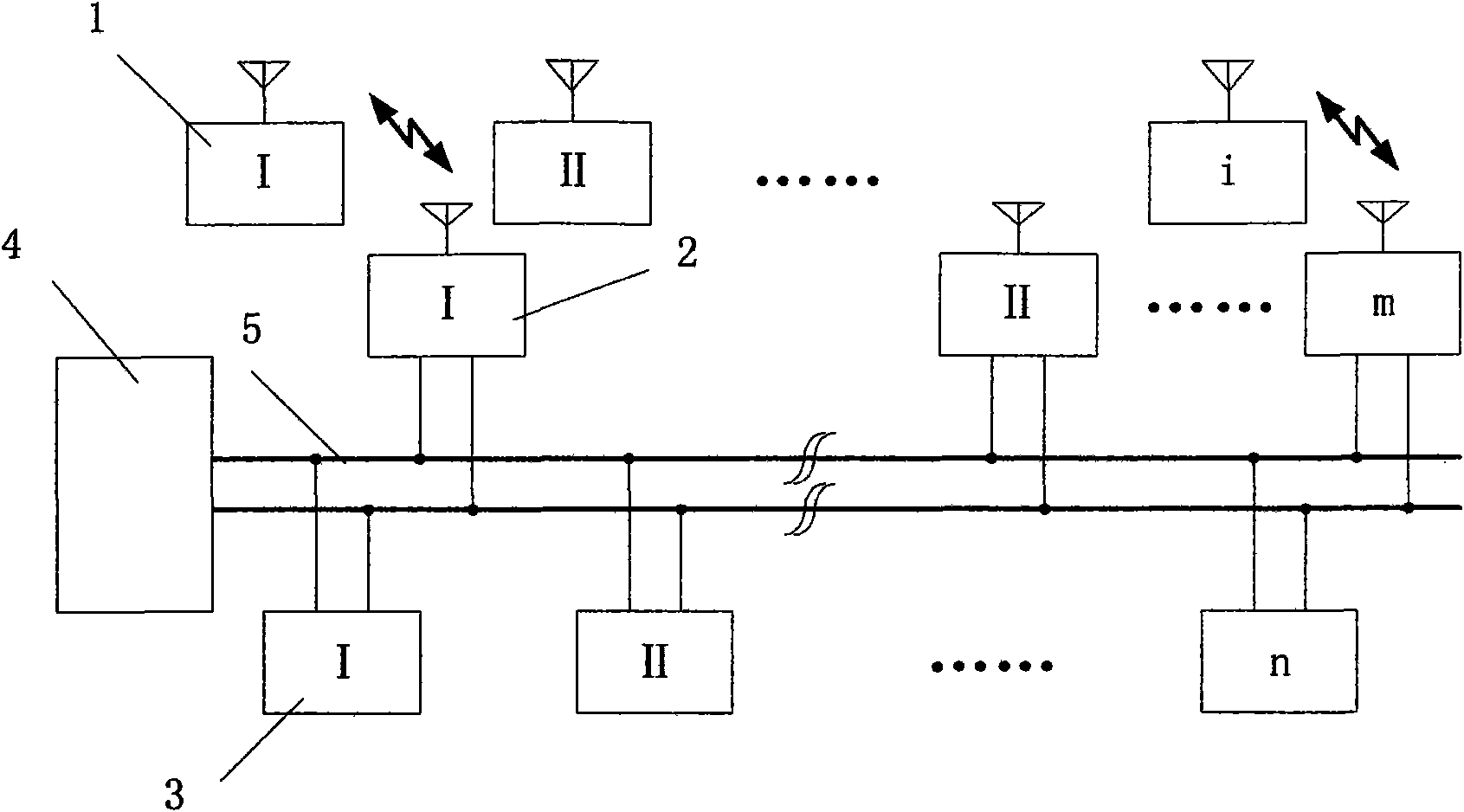

[0020] As shown in the figure, the coal mine mixed transmission sensor network of the present invention includes a field bus 5 connected to the monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com