Preparation method of stable oil displacement agent for clay and application thereof

A technology of clay stabilization and oil displacement agent, which is applied in earth drilling, chemical instruments and methods, and drilling compositions, etc. It can solve problems such as single performance, poor comprehensive performance, and unsatisfactory application effect, and the effect is obvious. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

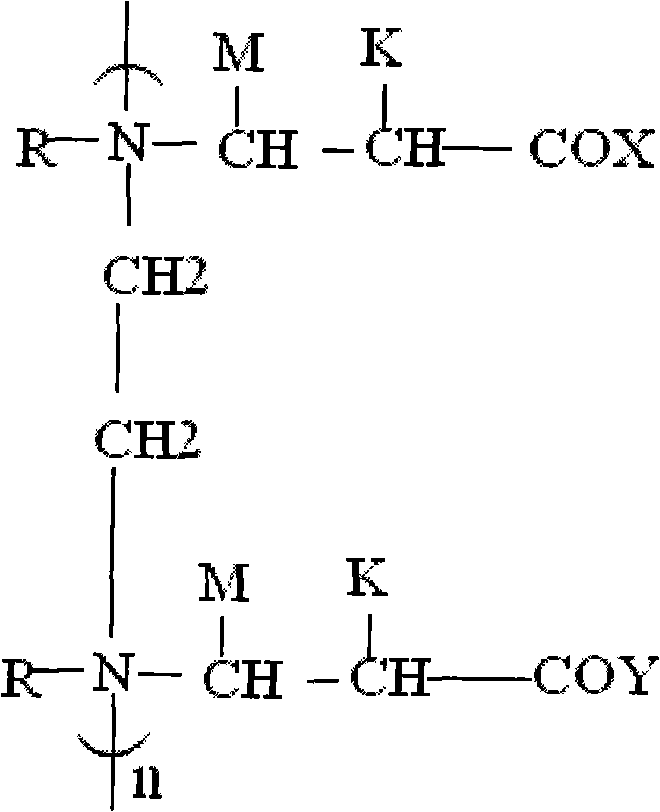

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, use dodecylamine as raw material preparation clay stabilized oil displacement agent:

[0013] Weigh 265kg of dodecylamine, raise the temperature to 75°C, add 154kg monomethyl fumarate dropwise, raise the temperature to 106°C to react for 7 hours after adding monomethyl fumarate dropwise, then add 69kg monoethanolamine, and stir evenly Then add 3.4kg of catalyst potassium ethylate, heat up to 116°C, react for 4 hours, then add 52kg of dichloroethane, stir evenly, add 160kg of potassium hydroxide, heat up to 134°C, react for 11 hours to obtain a clay-stabilized oil displacement agent .

Embodiment 2

[0014] Embodiment 2, prepare clay stabilized oil displacement agent with cetyl primary amine as raw material:

[0015] Weigh 220kg of hexadecyl primary amine, heat up to 64°C, add 126kg of methacrylic acid dropwise, raise the temperature to 94°C for 5 hours after adding methacrylic acid, then add 110kg of diethanolamine and 147kg of triethanolamine, stir After uniformity, add 6.2kg of catalyst sodium ethoxide, heat up to 152°C, and react for 2.5 hours, then add 32kg of dichloroethane, stir well, add 97kg of potassium hydroxide, heat up to 156°C, and react for 8 hours to obtain stable clay flooding agent.

Embodiment 3

[0016] Embodiment 3, use cetyl primary amine as raw material to prepare clay stabilized oil displacement agent:

[0017] Weigh 170kg of hexadecyl primary amine, raise the temperature to 64°C, add 98kg of methacrylic acid dropwise, after the dropwise addition of methacrylic acid, raise the temperature to 94°C and react for 5 hours, then add 85kg of diethanolamine and 113kg of triethanolamine, stir After uniformity, add 4.8kg of catalyst sodium ethylate, heat up to 152°C, react for 2.5 hours, then add 24.6kg of dichloroethane, stir evenly, add 74.7kg of potassium hydroxide, heat up to 156°C, react for 8 hours, and obtain stable clay oil repellant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com