Hybrid power plant and method of controlling such a power plant

A control method and engine technology, which are applied in the directions of engine control, gas turbine power plant, power plant, etc., can solve the problem of increasing fuel consumption rate and achieve the effect of reducing fuel consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

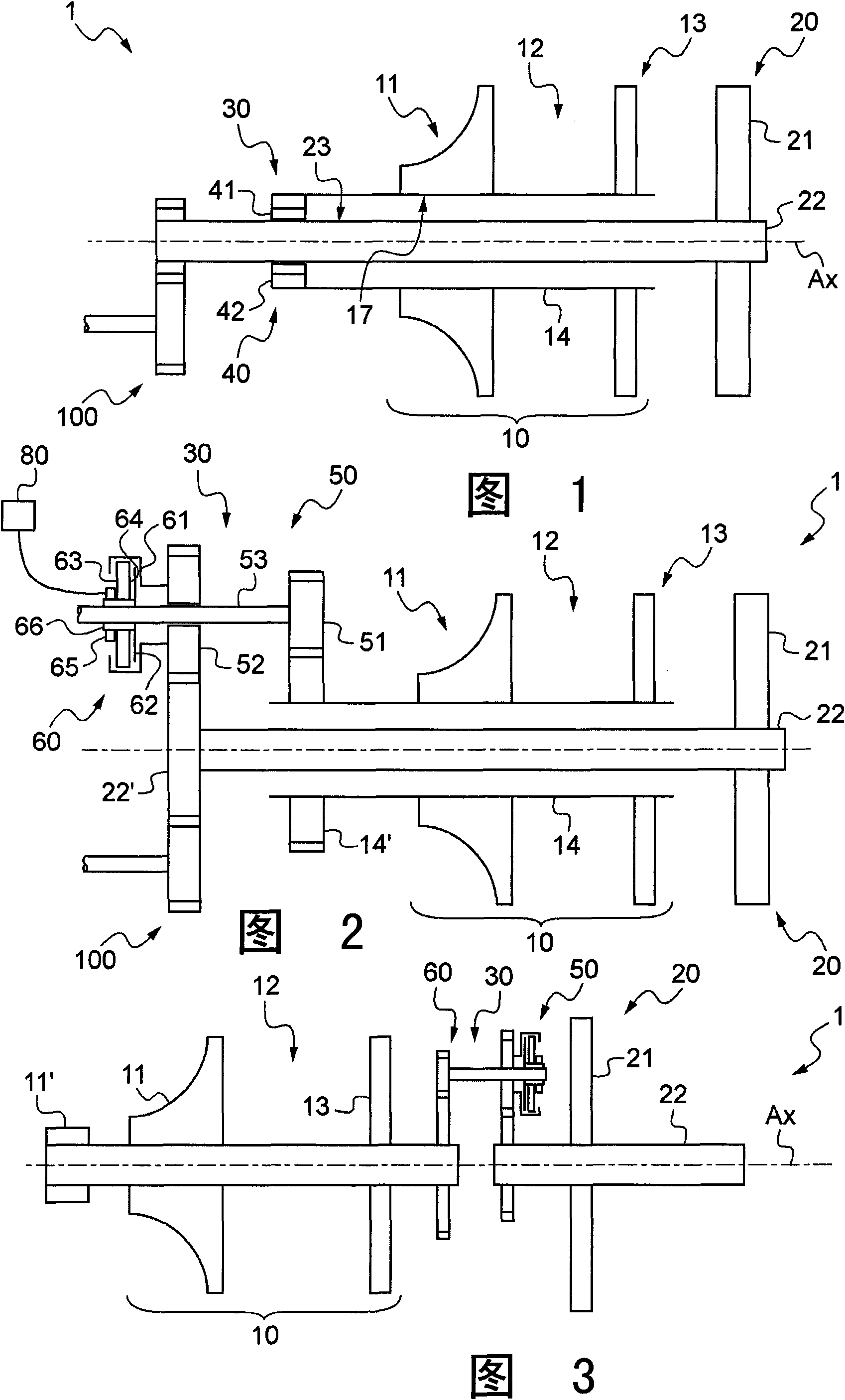

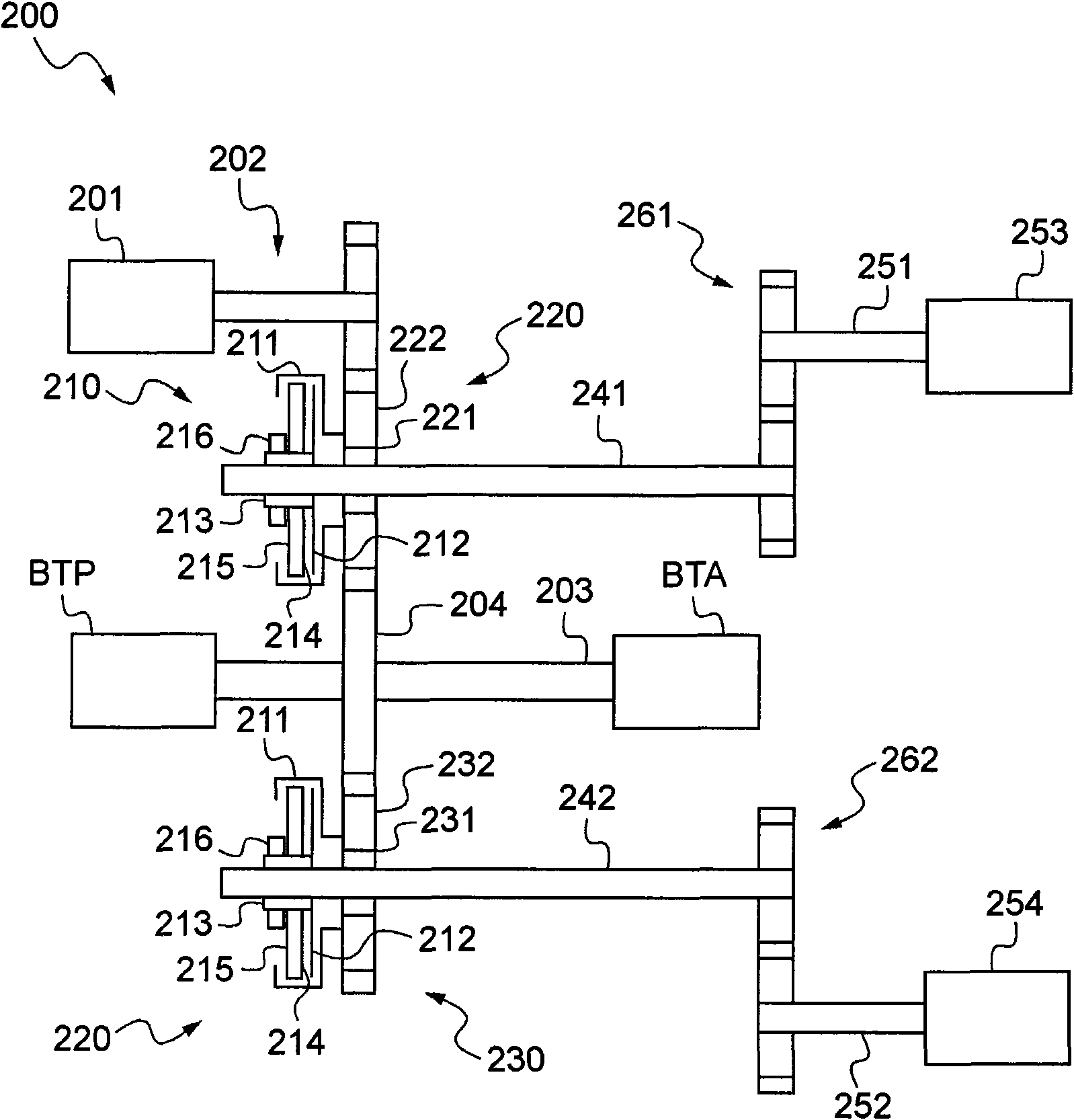

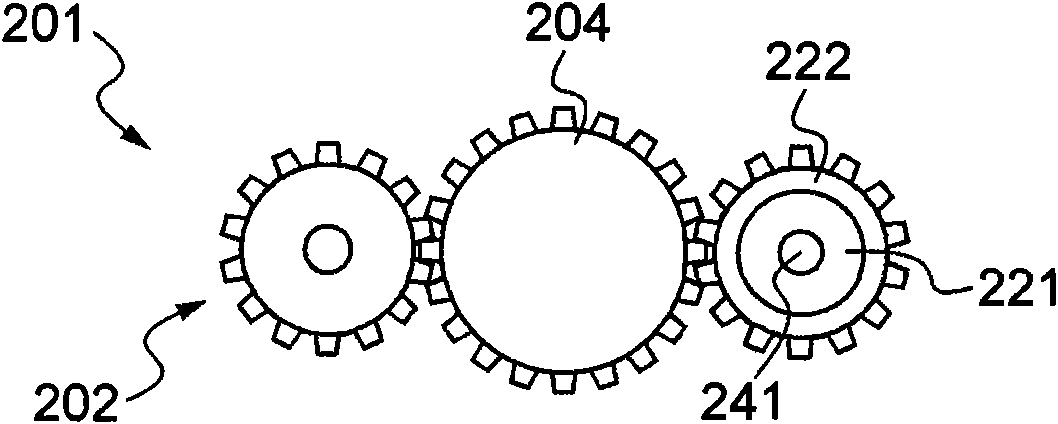

[0087] Figures 1 to 3 An innovative combined gas turbine 1 is shown which is suitable for use in an engine arrangement as claimed in the claims.

[0088] No matter in which embodiment, the combined gas turbine 1 includes a gas generator 10 and subsequent working components 20 in sequence along the direction of air flowing through the combined gas turbine 1 .

[0089] Along the direction of air flow through the combined gas turbine 1 , the gas generator is conventionally provided with at least one compressor 11 , a combustion chamber 12 , and at least one expansion turbine 13 connected to the compressor 11 via a main shaft 14 .

[0090] It should be seen that figure 1 with 2 Both show a single compressor 11, while image 3 An axial compressor 11' is shown followed by a centrifugal compressor 11.

[0091] It should be understood that the number of compressors and expansion turbines may be optimized according to requirements, without limiting the scope of the invention.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com