Apparatus for the separation of solid particles from water and haudraulic installation containing such separation apparatus

A solid particle and equipment technology, applied in the field of energy conversion equipment, can solve the problems of reduced solid particle content, ineffective sand tank tunnels, increased hydraulic equipment installation costs and operating costs, and achieve the effect of reducing workload and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

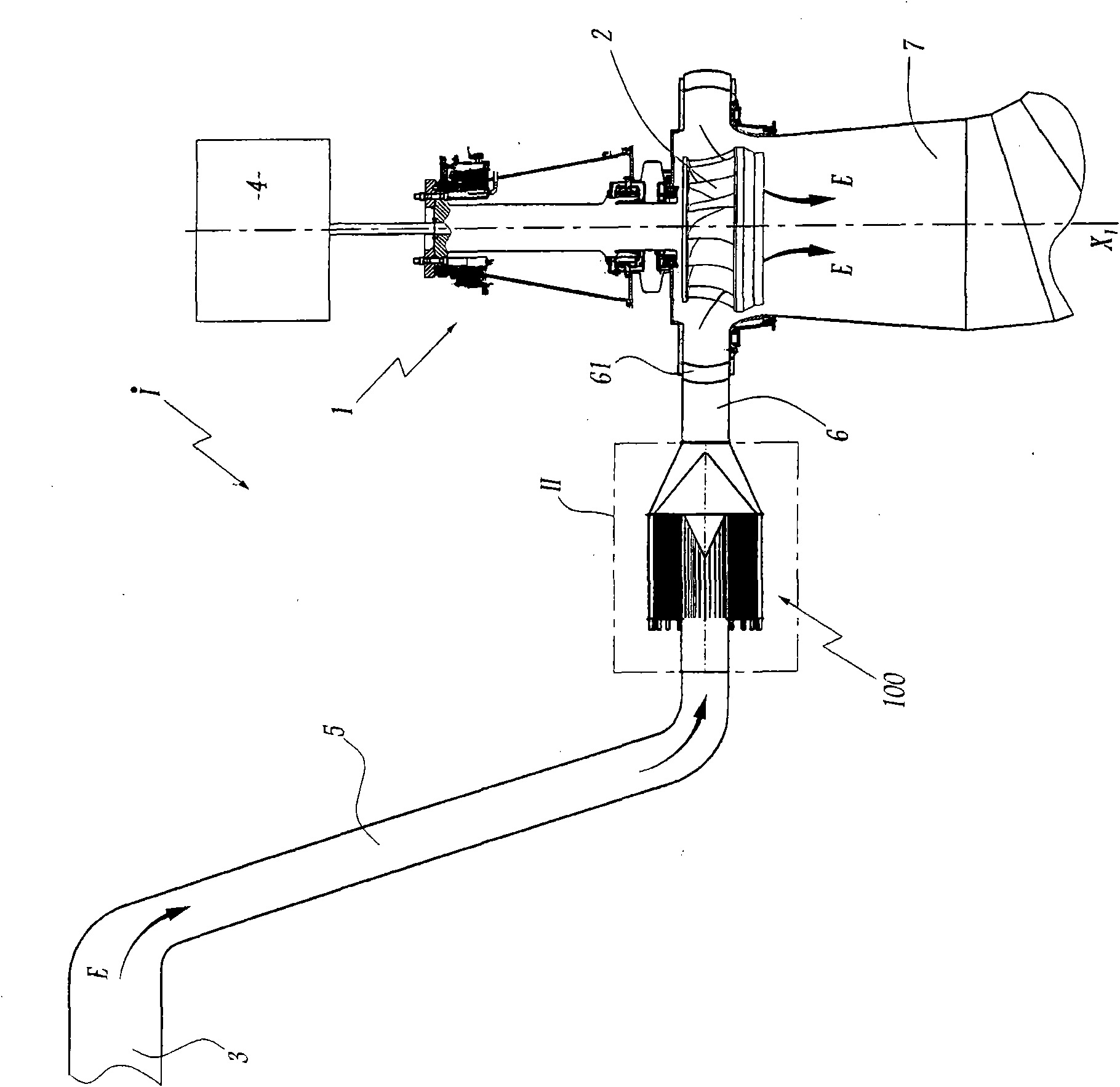

[0033] figure 1 The shown plant I comprises a Francis type turbine 1 with its impeller 2 for passing a forced flow E from a water inlet 3 set about a vertical axis X 1 Rotating, the above-mentioned water inlet 3 takes the flow from a reservoir, such as a dam, or the flow from an undammed river. The turbine 1 is coupled to an alternator 4 which delivers an alternating current to an electrical network (not shown) as the impeller 2 rotates.

[0034] The hydraulic pipe 5 that brings the water flow E into the impeller 2 extends between the water inlet 3 and a supply tank 6 equipped with guide vanes 61 for regulating the water flow E. Downstream of the device I is provided a suction line 7 for conveying the water flow E.

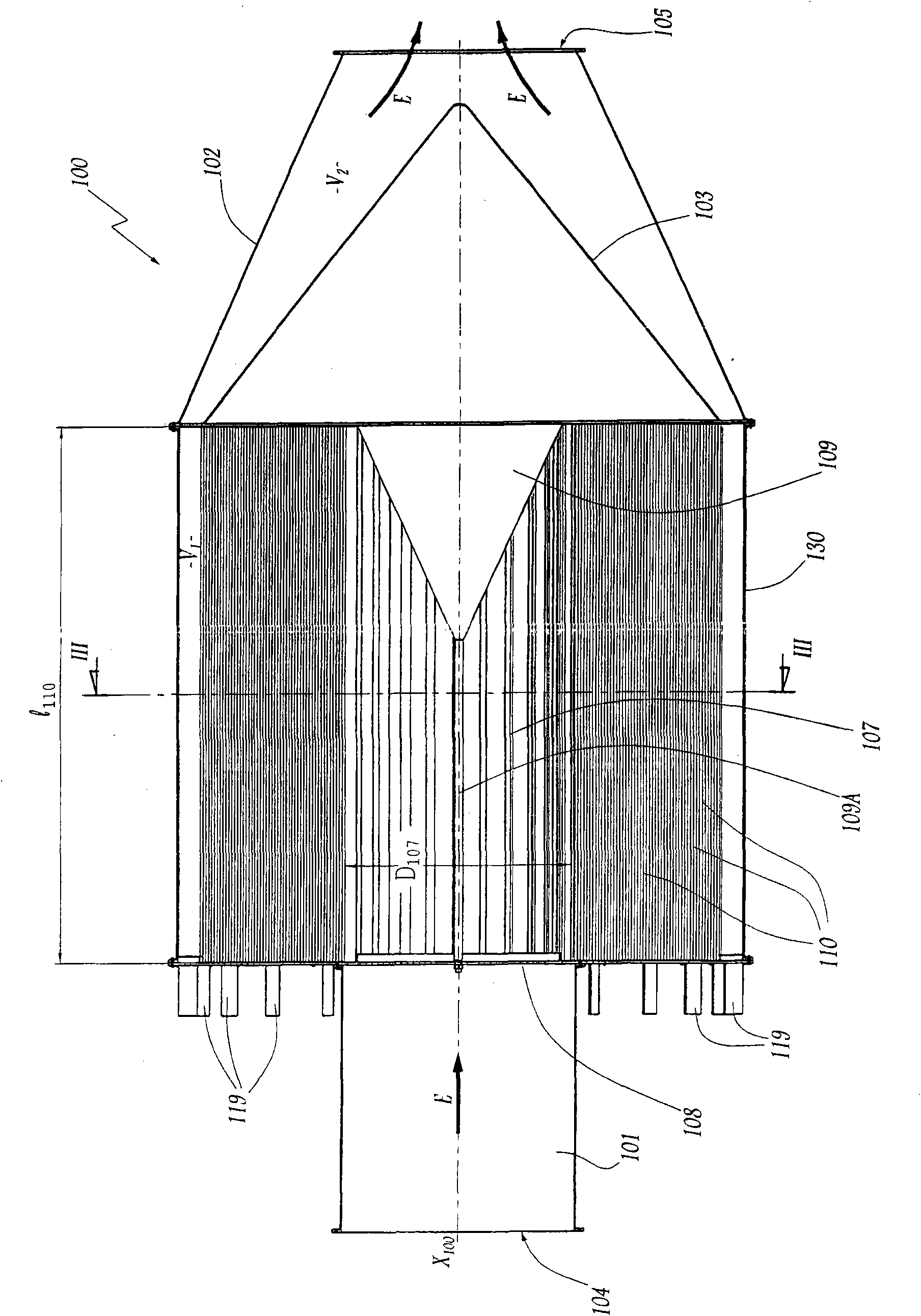

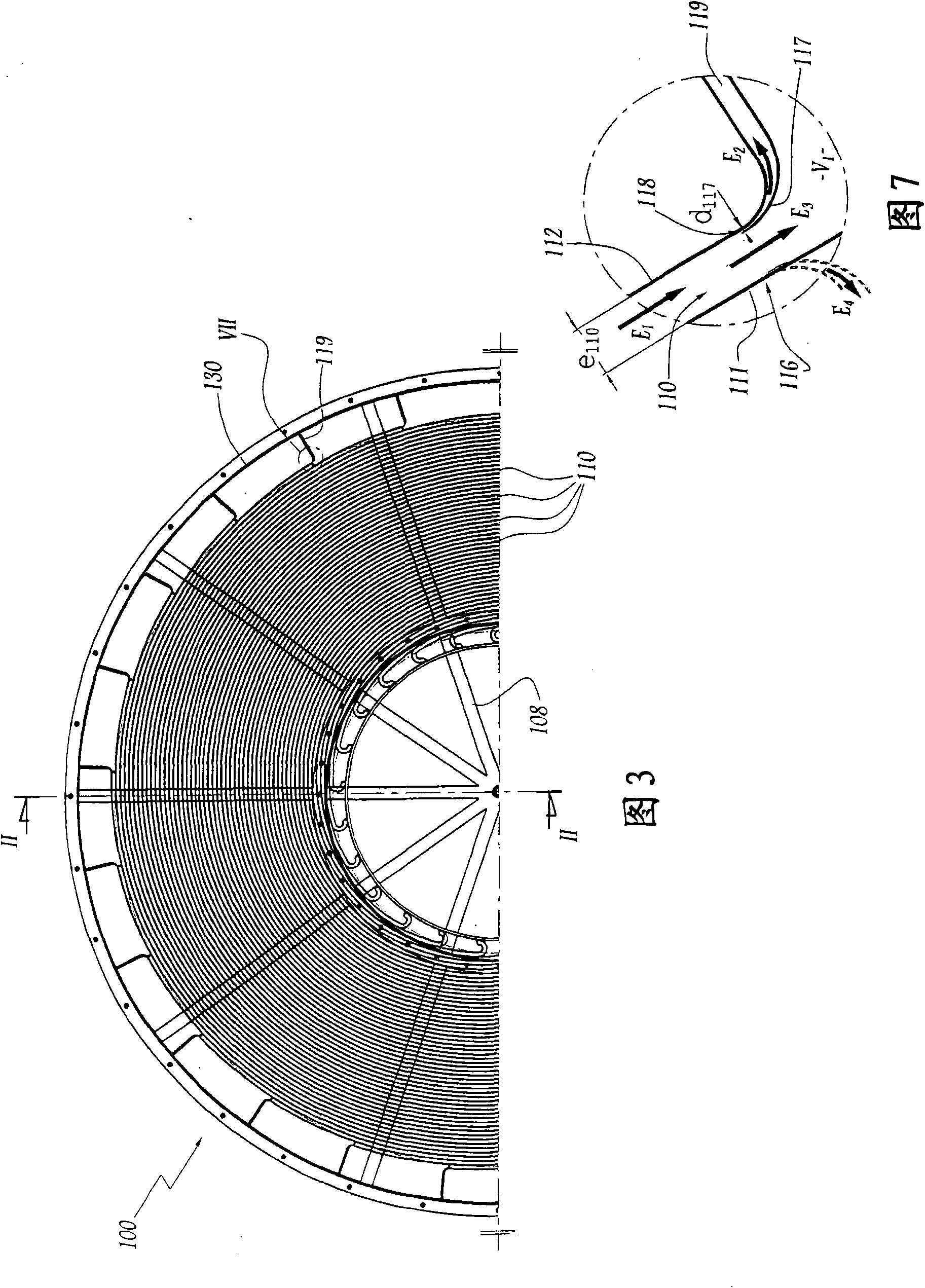

[0035] The device 100 interposed between the water inlet 3 and the supply tank 6 serves to separate the solid particles found in the water flow E from the water constituting this flow. The device 100 comprises a cylindrical inlet duct 101 having a circular cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com