Method for preparing powdery sample of coil paper of cigarette for thermal analysis experiment

A cigarette paper and powder technology is applied in the field of preparing powder samples for experiments, which can solve the problems of small sample volume, poor fluidity and low bulk density, and achieve the effects of uniform sample size, good fluidity and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

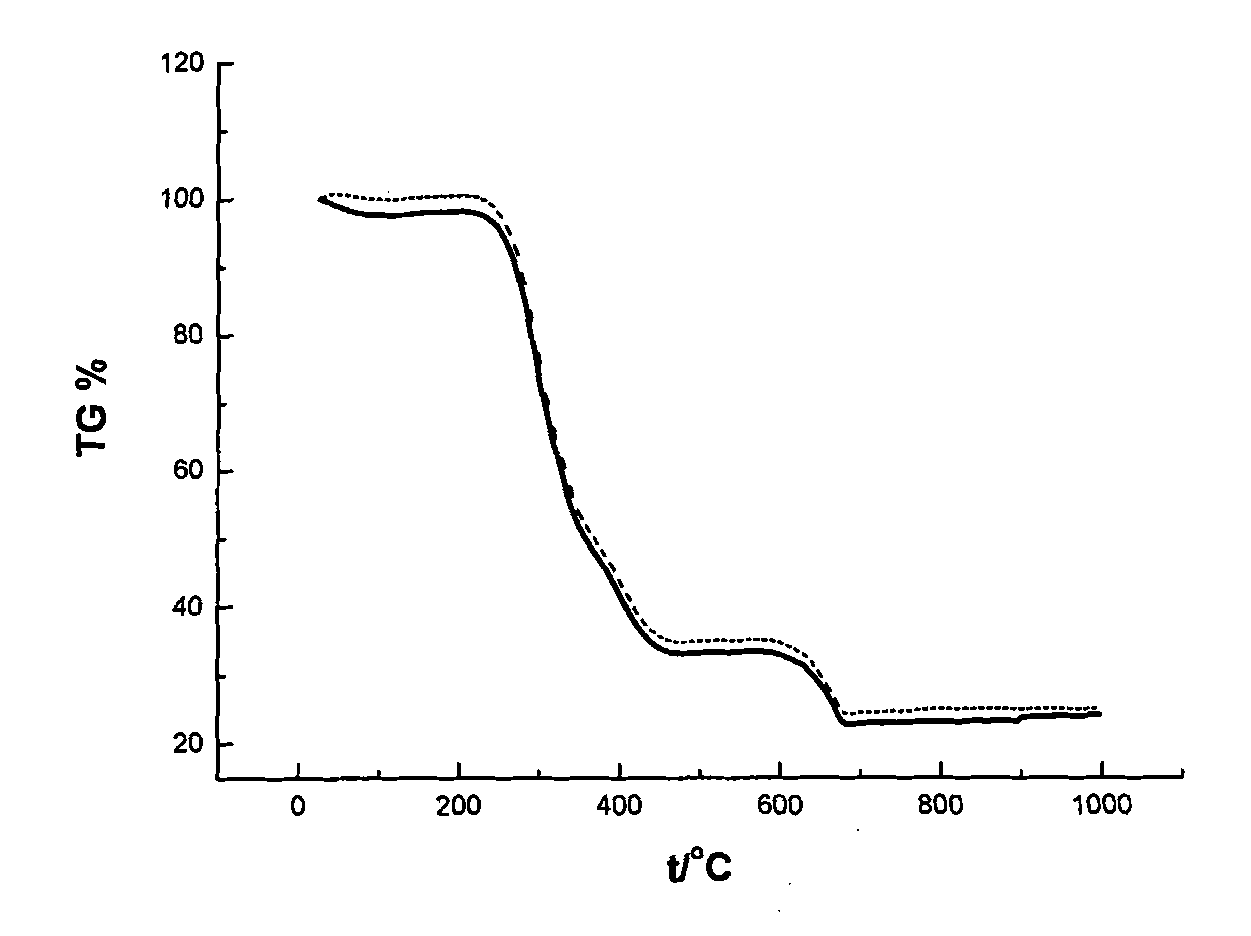

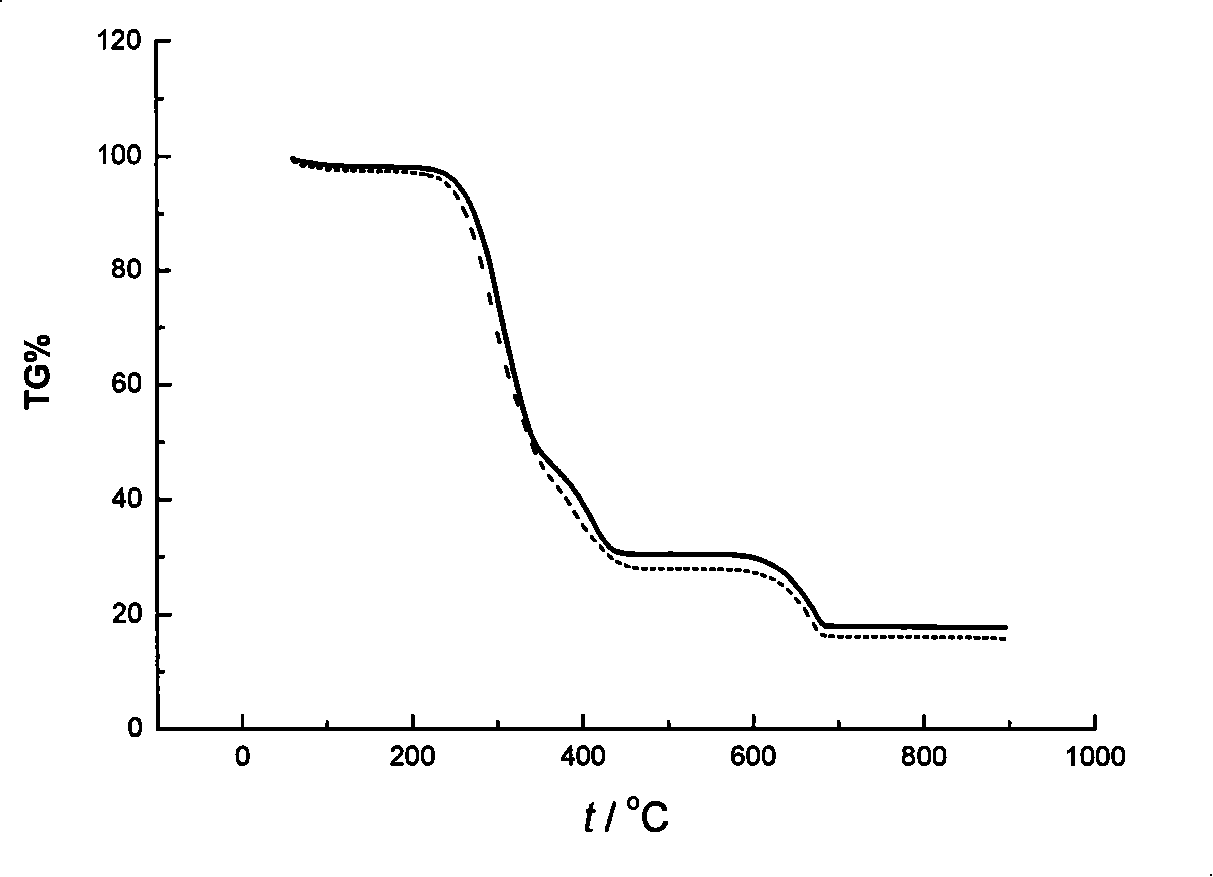

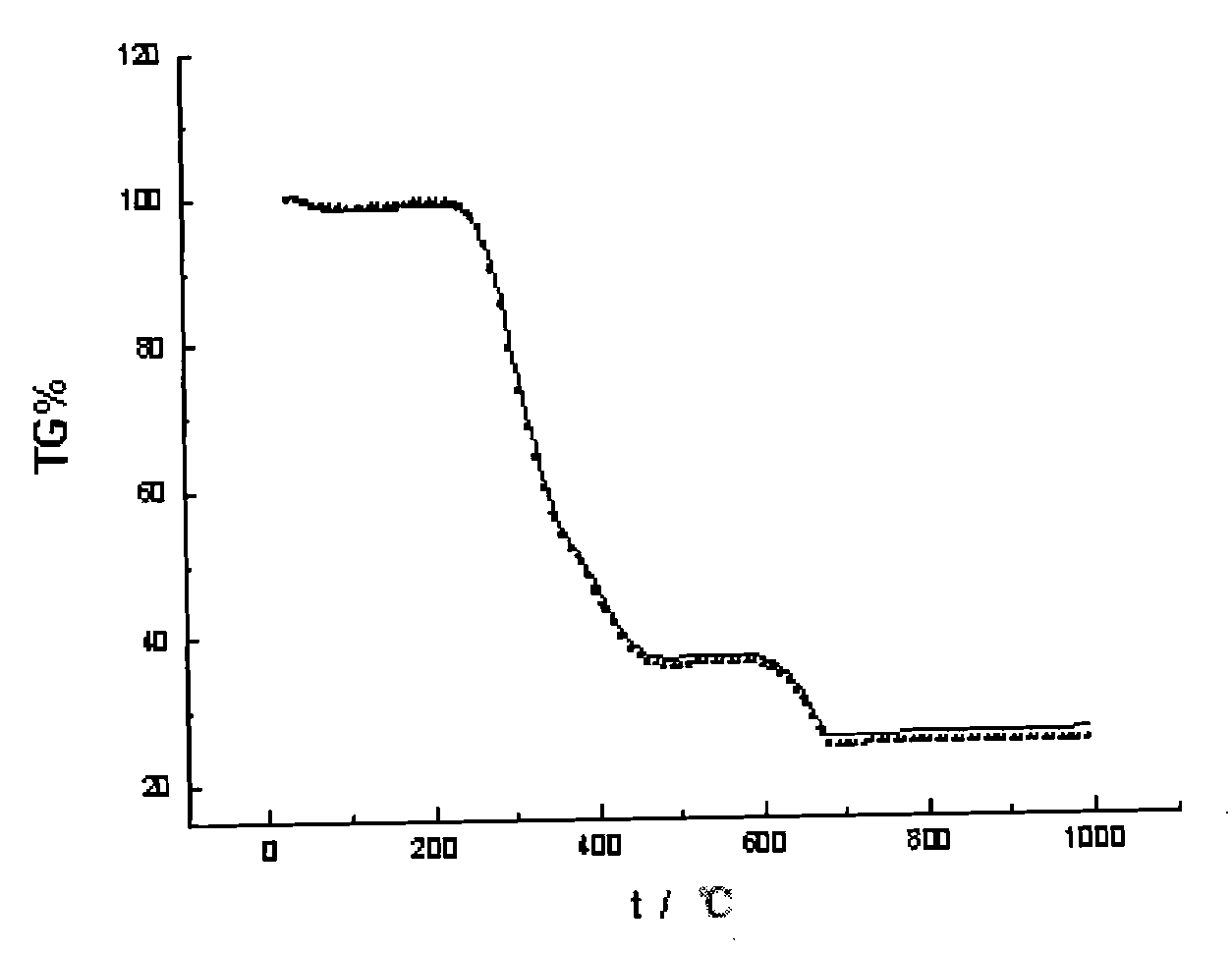

Image

Examples

Embodiment Construction

[0012] The related technical problems of the present invention will be further described in detail below. First, the method of the present invention is compared with three sample preparation methods in the prior art.

[0013] The sample prepared by this method is compared with the first kind of method of manual shredding, and the advantage of the method of the present invention is: the method of the present invention is time-saving, and cycle is short. The comparative analysis of the experimental data is shown in Table 1.

[0014] Table 1 The present invention prepares sample and compares with method 1 preparation sample

[0015]

Sample preparation time

/ 10g sample

Sample volume /

Hour

sample size

Bulk density

(Cl - , SO 4 2- parallel sample

The relative standard deviation between

Difference)

burning heat level

line-to-sample phase

deviation from the standard

Difference ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com