Cone bit palm axis R-groove axial position measuring instrument for oil

A roller cone bit and groove axial technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems such as downhole accidents, bearing wear, failure, etc., achieve intuitive readings, simplify inspection procedures, and simple measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

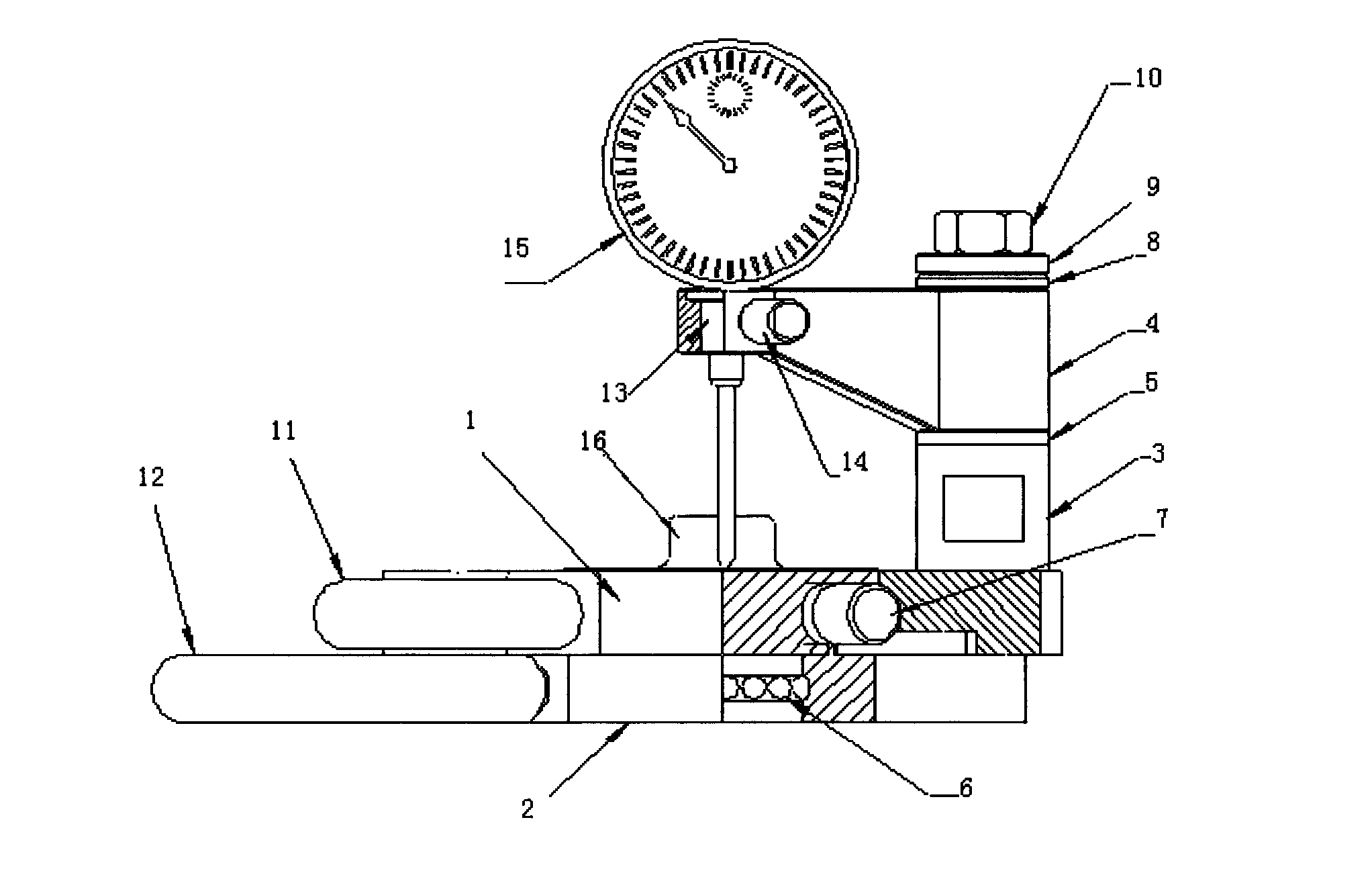

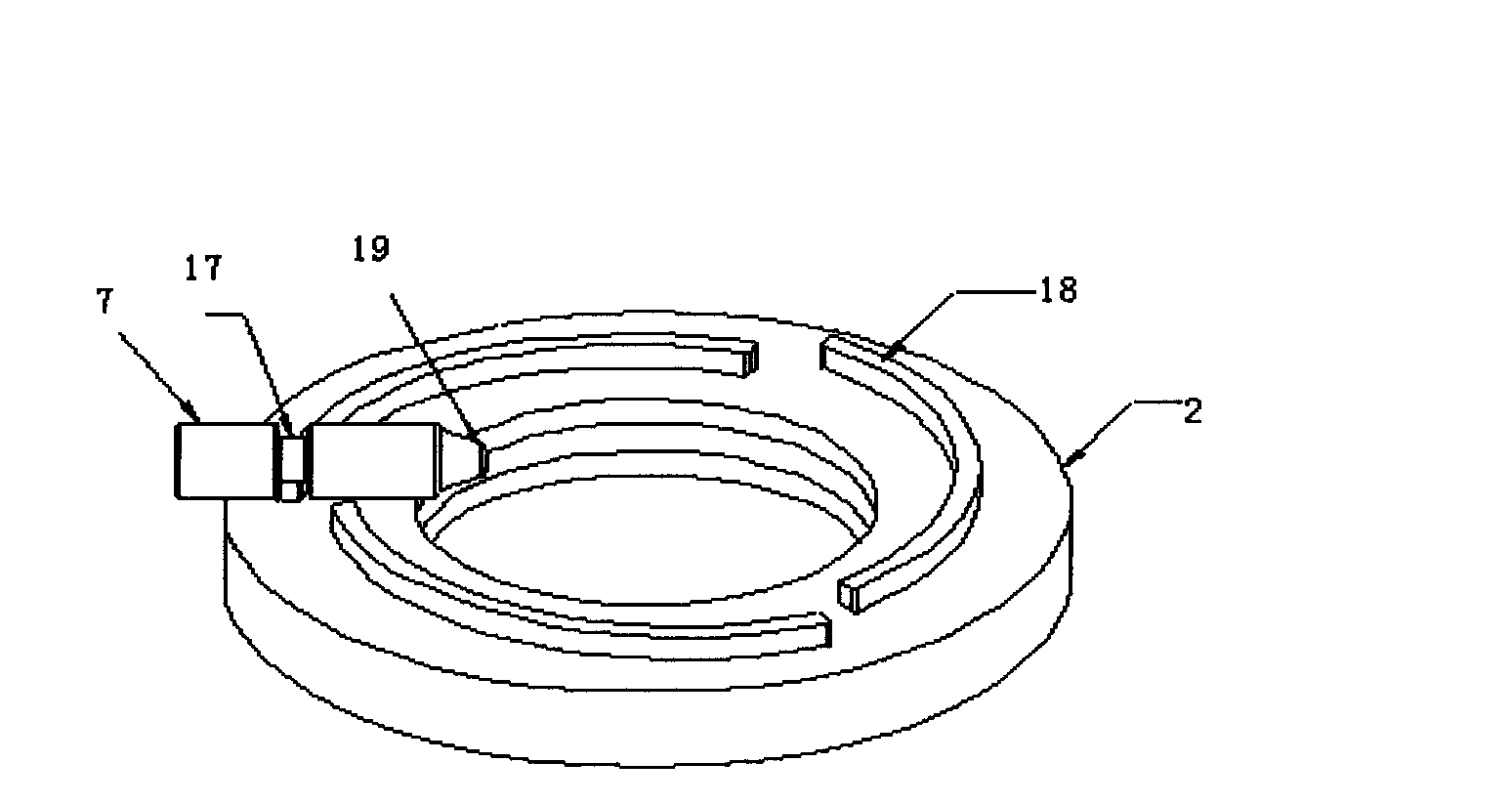

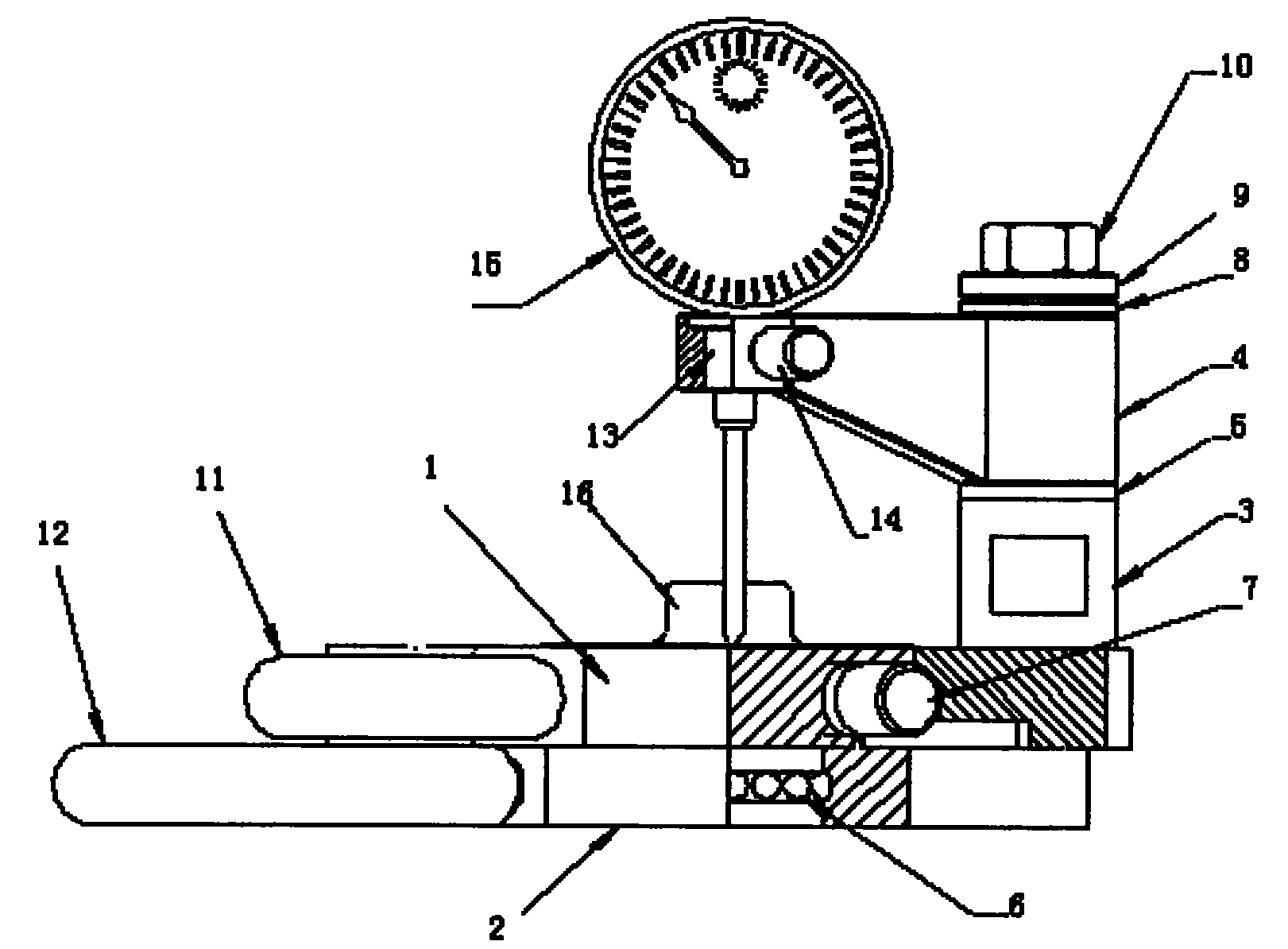

[0012] Example: such as figure 1 , figure 2 As shown, three holes forming an angle of 120° with each other on the same radial position are provided on the base body (1), and the probe head body (7) is matched to form a square hole or a cylindrical hole. Such as figure 2 As shown, there are grooves (17) on the probe body (7), and the grooves (17) of the three probe bodies (7) cooperate with the plane spiral ribs (18) on the locking disc (2), and the handle (11), (12) make the base body (1) and the locking disc (2) rotate relative to each other, and under the drive of the plane spiral rib (18), push the three probe bodies (7) to move inward, so that the three probe heads (19) protrudes inwardly from the base body (1), and is locked in the R groove of the palm shaft (16) of the tested tooth. The dial indicator (15) is clamped on the rotating arm (4) through the split sleeve (13) and the fixing screw (14), and the other end of the rotating arm (4) is connected to the rotating...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap