Combined type support rack

A combined and knotted technology, used in display hangers, display shelves, display stands, etc., can solve the problems of slow assembly, troublesome use, weak positioning force, etc., and achieve the effect of rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable a further understanding and understanding of the purpose, features and effects of the present invention, please refer to the accompanying drawings for a detailed description below:

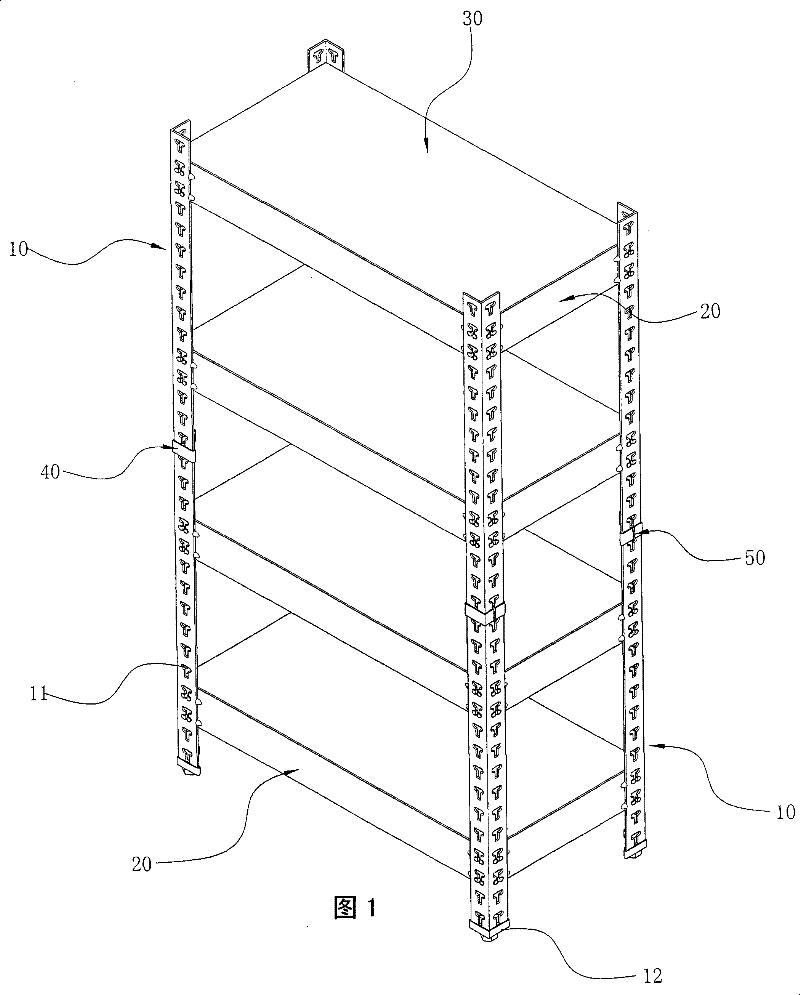

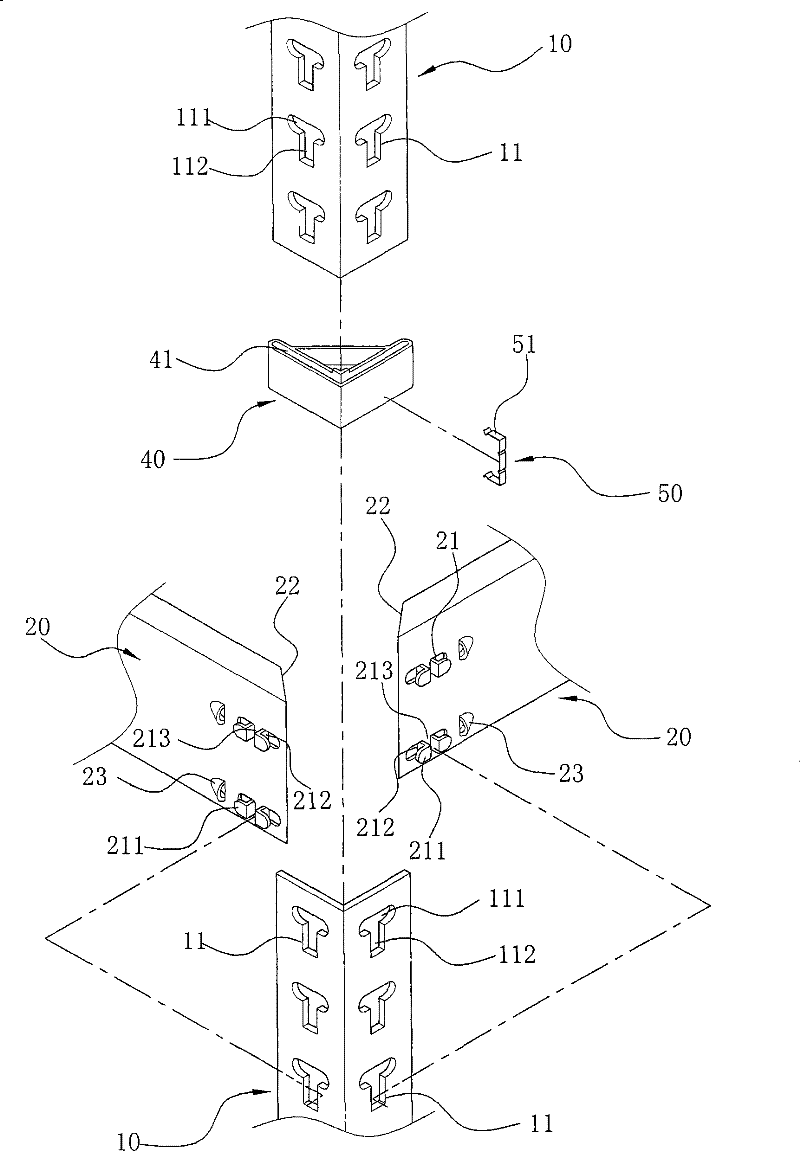

[0036] by the invention Figure 1 to Figure 6 As shown, the upright pole 10 and the supporting pole 20 are mainly embedded in the fastening hole 11 by using the protruding clamping block 21, and the storage board 30 is laid on it to complete the combination of the bearing frame.

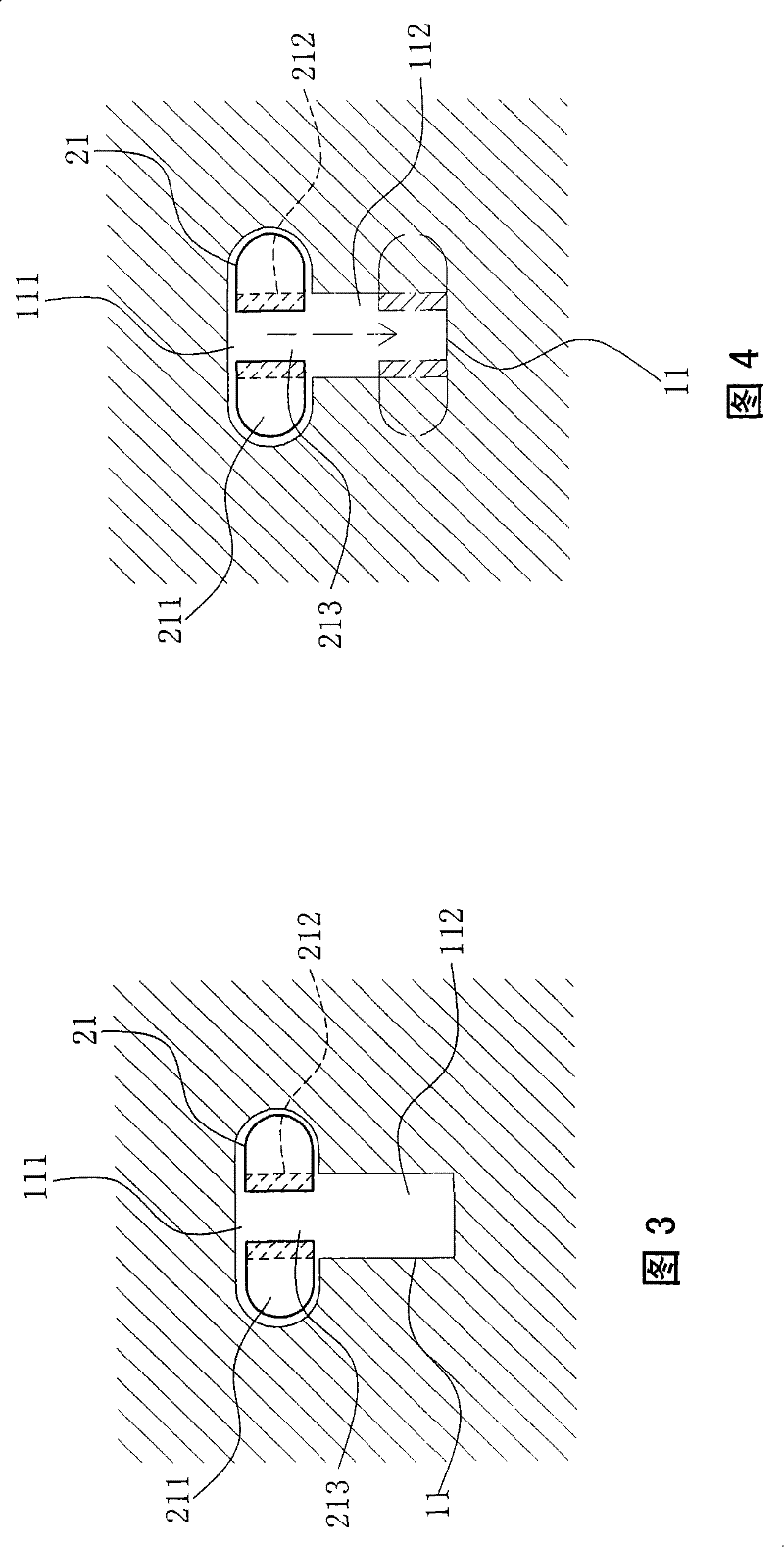

[0037] Among them, first by figure 1 and figure 2 As shown, the fastening hole 11 is vertically pierced on the two-sided edge planes of the right-angled vertical rod 10, so that one side of the fastening hole 11 can become a larger penetration portion 111, and the other side becomes a smaller fastening portion 111. Knot 112, and because the vertical rod 10 needs to be supported against the ground, there is a liner 12 on its bottom end, and a height adjustment screw is combined on the liner 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com