Energy-saving and environment-friendly industrialized production equipment and facility of button mushrooms

A factory-like, energy-saving technology, applied in energy-saving measures, agricultural machinery and equipment, botanical equipment and methods, etc., can solve the problems of high cost of Agaricus bisporus, difficulty in obtaining profits, high operating costs, etc., to reduce equipment and personnel input, reduce production costs, and speed up fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

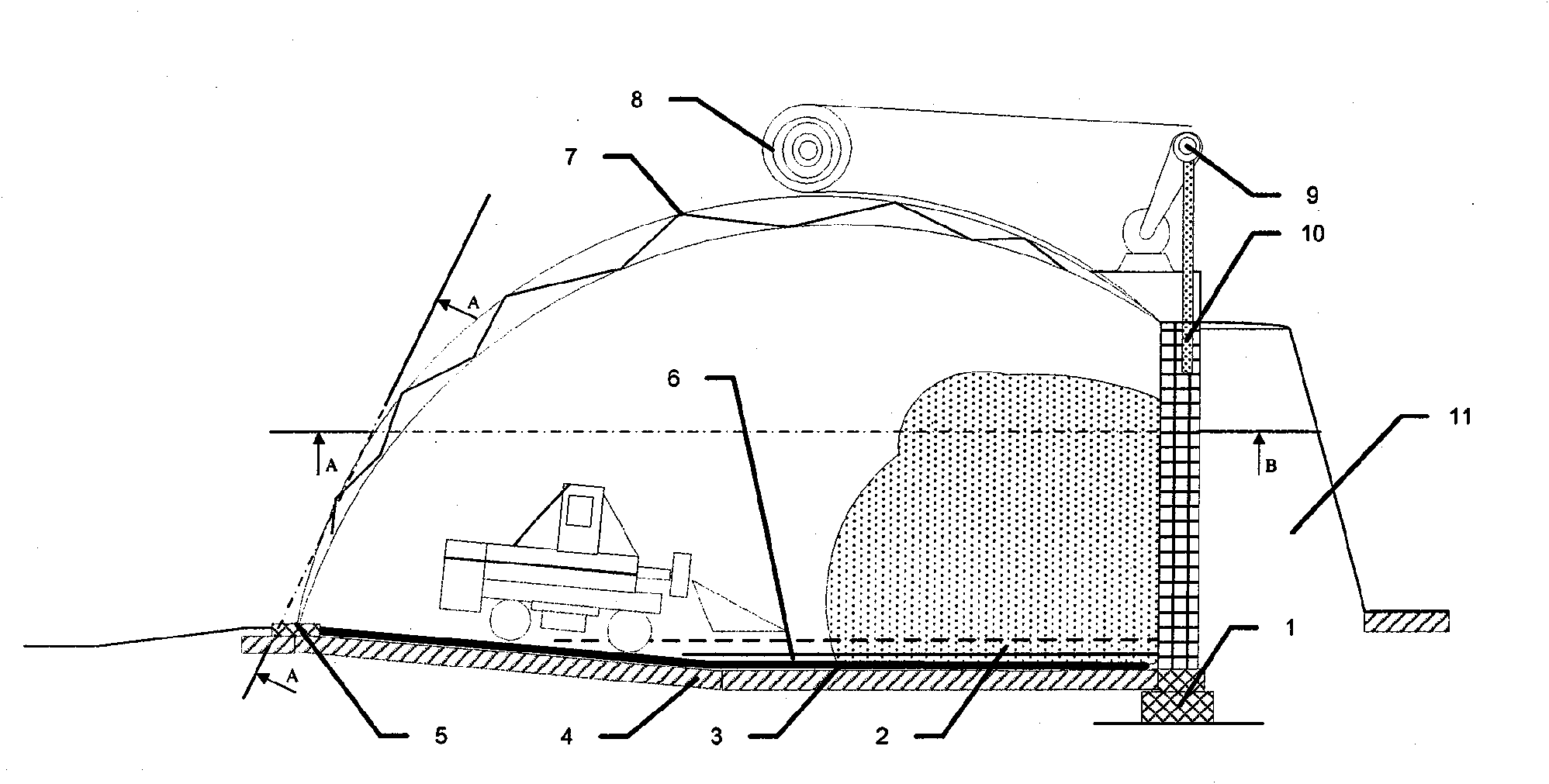

[0133] In order to achieve the purpose of industrialized annual (year-round) production and meet the requirements of reducing production process, reducing equipment and facilities, reducing investment and energy saving and consumption reduction, in the production line involved in the present invention, five kinds of facilities need to be built and seven kinds of equipment manufactured . According to the actual production process, the functions, characteristics and usage methods of each part of the equipment and facilities will be described in detail below.

[0134] Note: The mixture of straw and poultry manure before secondary fermentation is called "compost", and after secondary fermentation, it is called "compost".

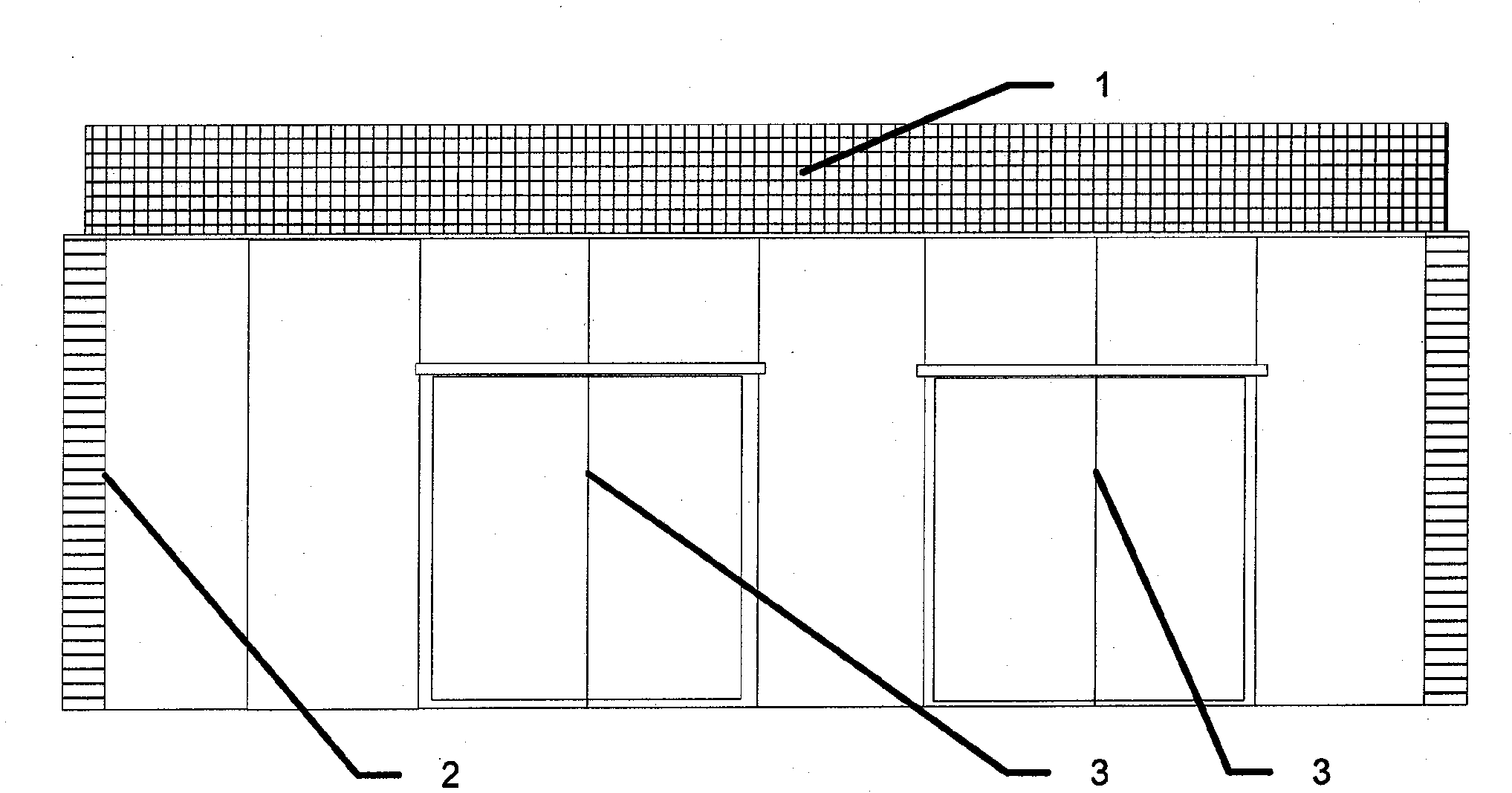

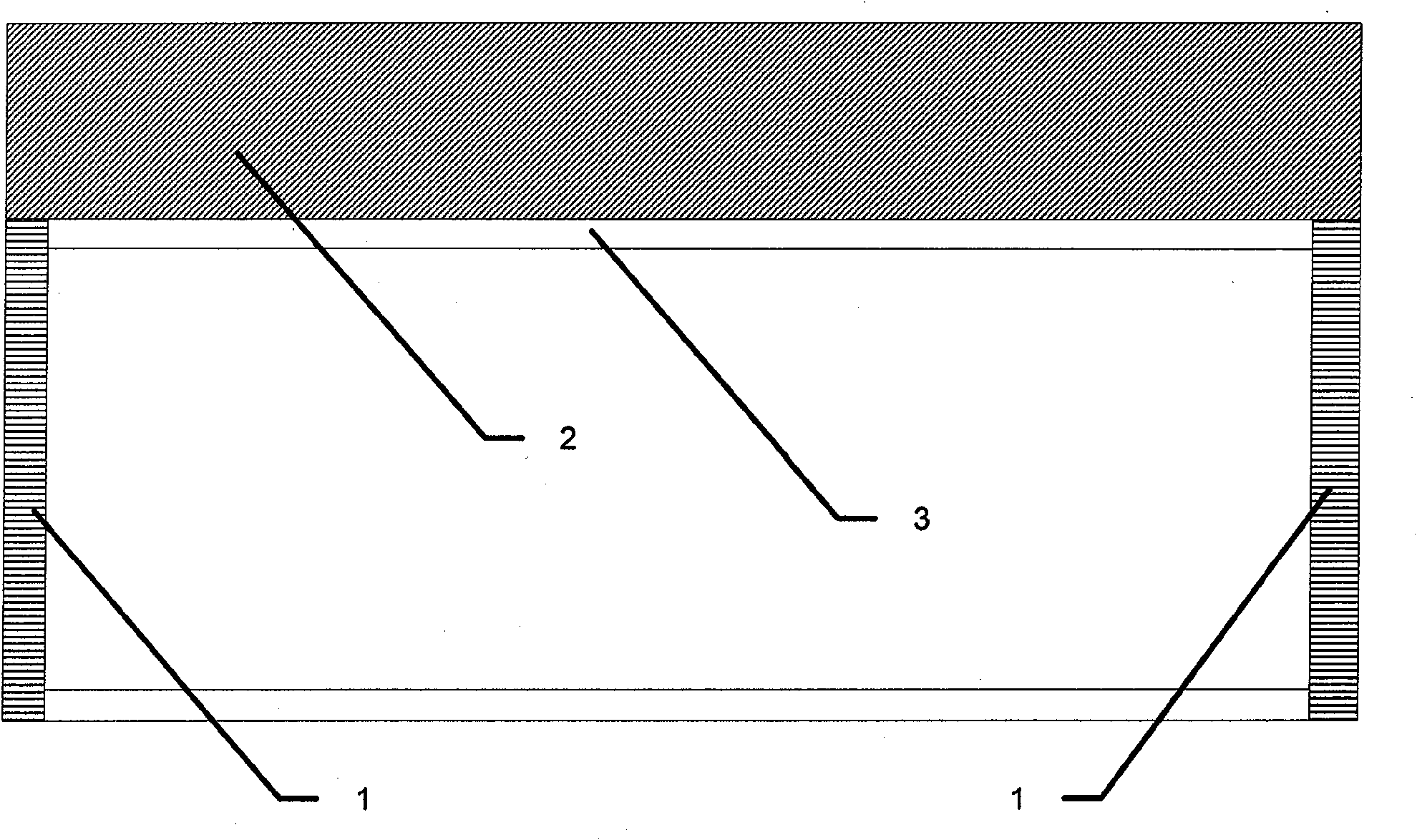

[0135] 1. Energy-saving mixing greenhouse ( figure 1 , figure 2 , image 3 )

[0136] The role of each part:

[0137] 1. The foundation of the back wall of the greenhouse. Because the loader needs to work in the mixing shed and stack the mixed compost in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com