Right hexagonal steel-concrete combined hollow double lattice floor and manufacturing method thereof

A regular hexagonal, reinforced concrete technology, applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve problems such as the increase in the cost of ceiling and ceiling, achieve EI improvement, ensure structural rigidity and strength, The effect of reducing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

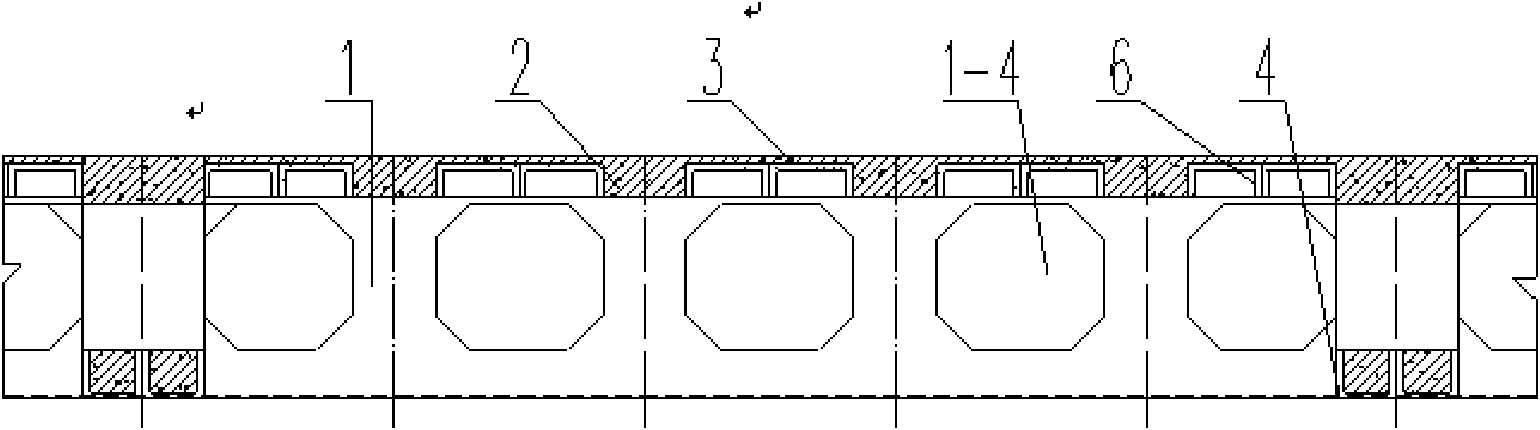

[0020]Embodiment of the present invention: when constructing a multi-functional cultural hall with a large span of 3 to 5 floors, the floor is preferably carried out by using the method for making a regular hexagonal steel-concrete combined hollow double grid beam floor of the present invention Make, be about to make the plane shape of floor cover into regular hexagon, adopt hexagonal reinforced concrete frame structure to form six sides of regular hexagon of this regular hexagonal floor, and make the diagonal length L of this regular hexagon ( That is, the span) is 30 meters ≤ L ≤ 48 meters, in the closed regular hexagon formed by the hexagonal reinforced concrete frame, the steel-concrete composite vierendeel beams are respectively arranged along the three directions parallel to the corresponding two sides of the regular hexagon, For example, when L=36m, three steel-concrete composite vierendeel beams are arranged in parallel at equal distances in each direction, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com