Heat-insulating and heat-preserving wall

A technology for thermal insulation and wall body, applied in the direction of walls, building components, buildings, etc., can solve the problems of easy distribution to the outside, poor wall thermal insulation effect, etc., to ensure firmness, reduce decoration costs, and scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

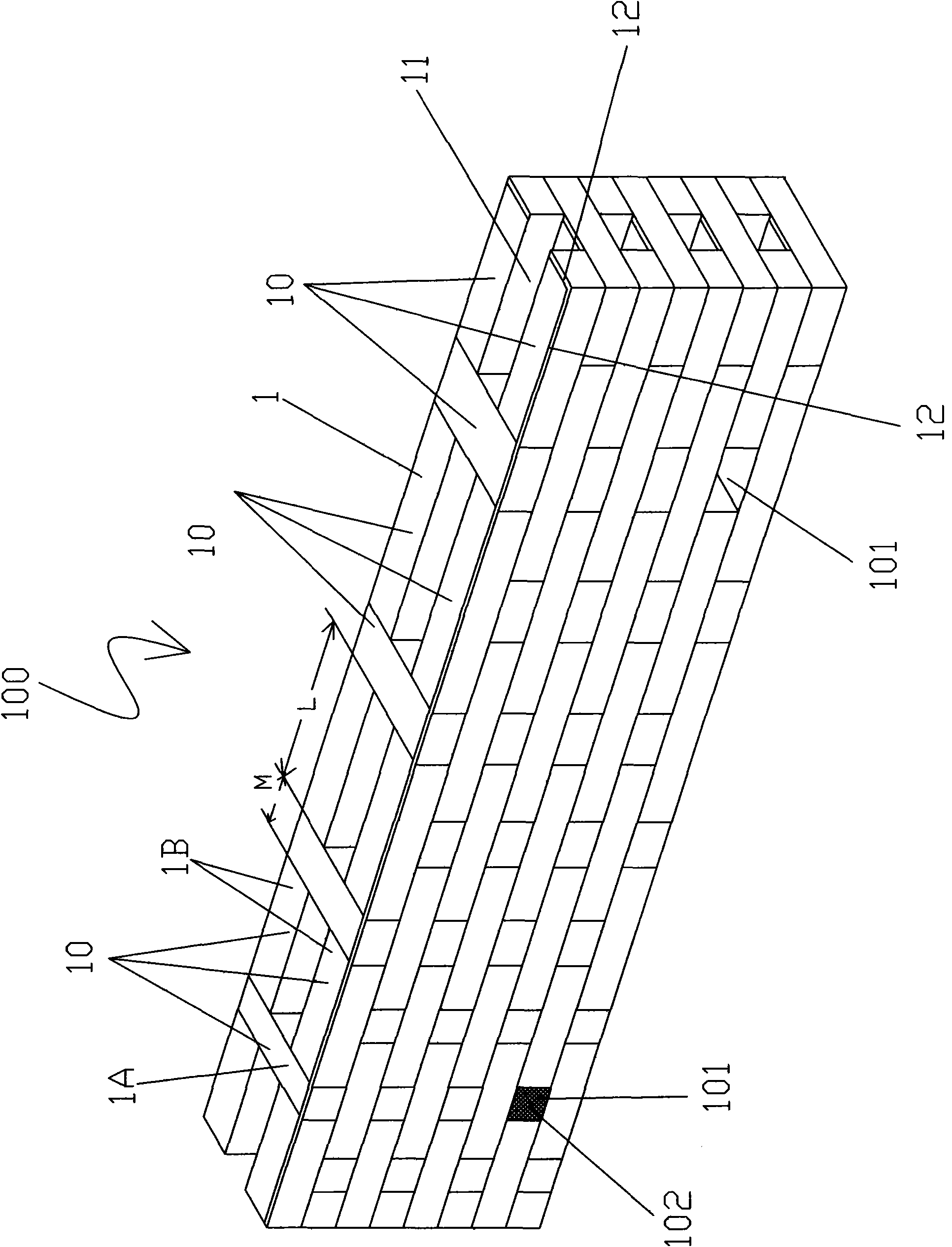

[0022] A thermal insulation wall, the wall 100 is formed by stacking several layers of bricks, each layer includes several combination units 10, and the combination units 10 are arranged in sequence; wherein each combination unit 10 includes a The set brick 1A and two parallel bricks 1B arranged along the length direction of the wall; the length L of the described brick 1 is greater than twice the width M; so that there is an insulating gap 11 between the two vertical bricks, the described The combined units 10 of the upper and lower adjacent layers are arranged in a staggered position, and the heat insulation gaps 11 between each layer are communicated to form a heat insulation layer in the wall.

[0023] The brick 1A arranged horizontally on the upper layer of the upper and lower connected layers of the wall body 100 is located in the middle of two parallel bricks 1B arranged along the length direction of the wall body on the lower layer.

[0024] The building length of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com