Low temperature high pressure gas hydrate replacement reaction kettle and system

A gas hydrate, low-temperature and high-pressure technology, which is applied in chemical/physical/physicochemical fixed reactors, pressure vessels/vacuum vessels, pressure vessels used in chemical processes, etc., can solve the problems of poor high-pressure rotary sealing performance and achieve Run Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

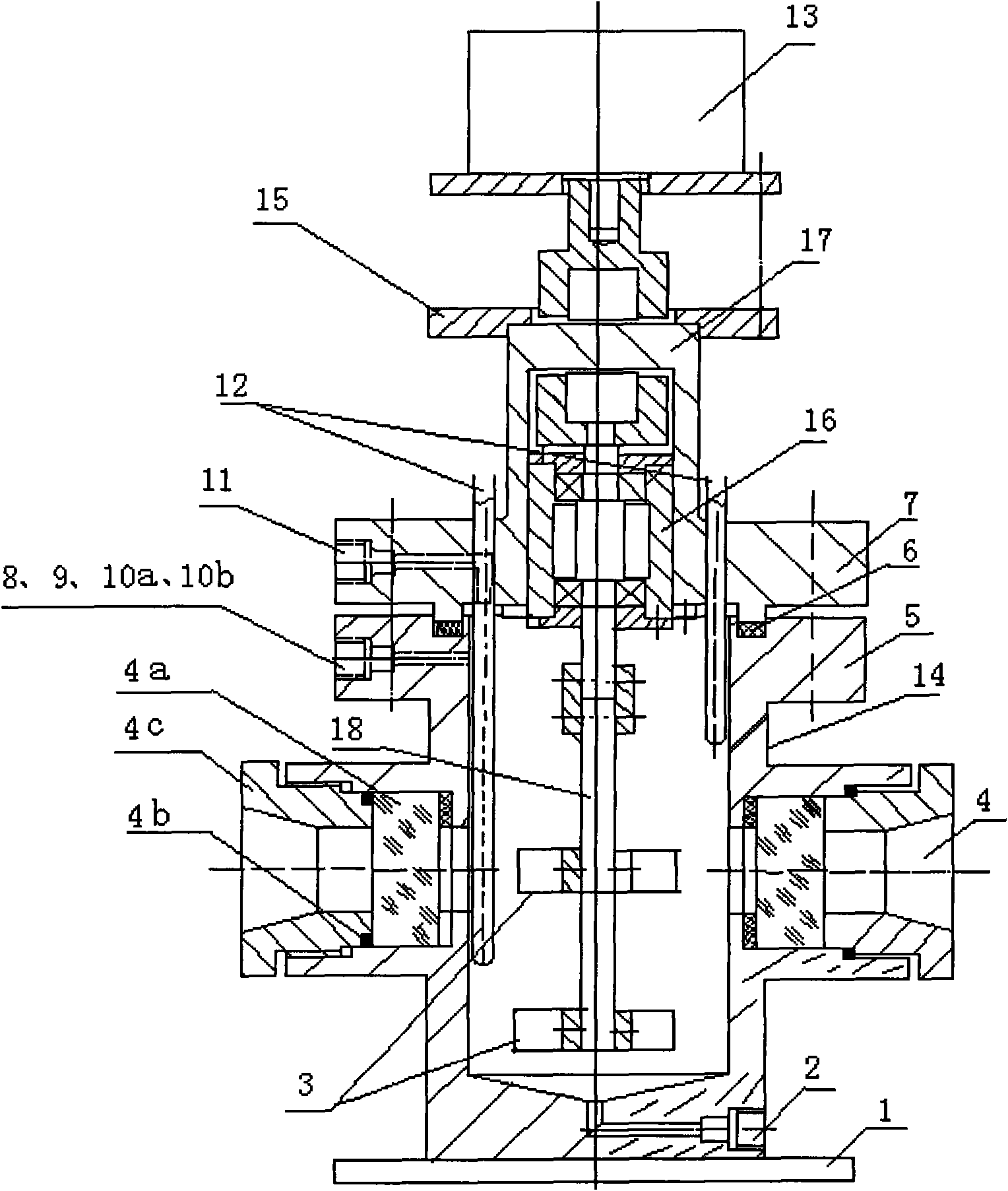

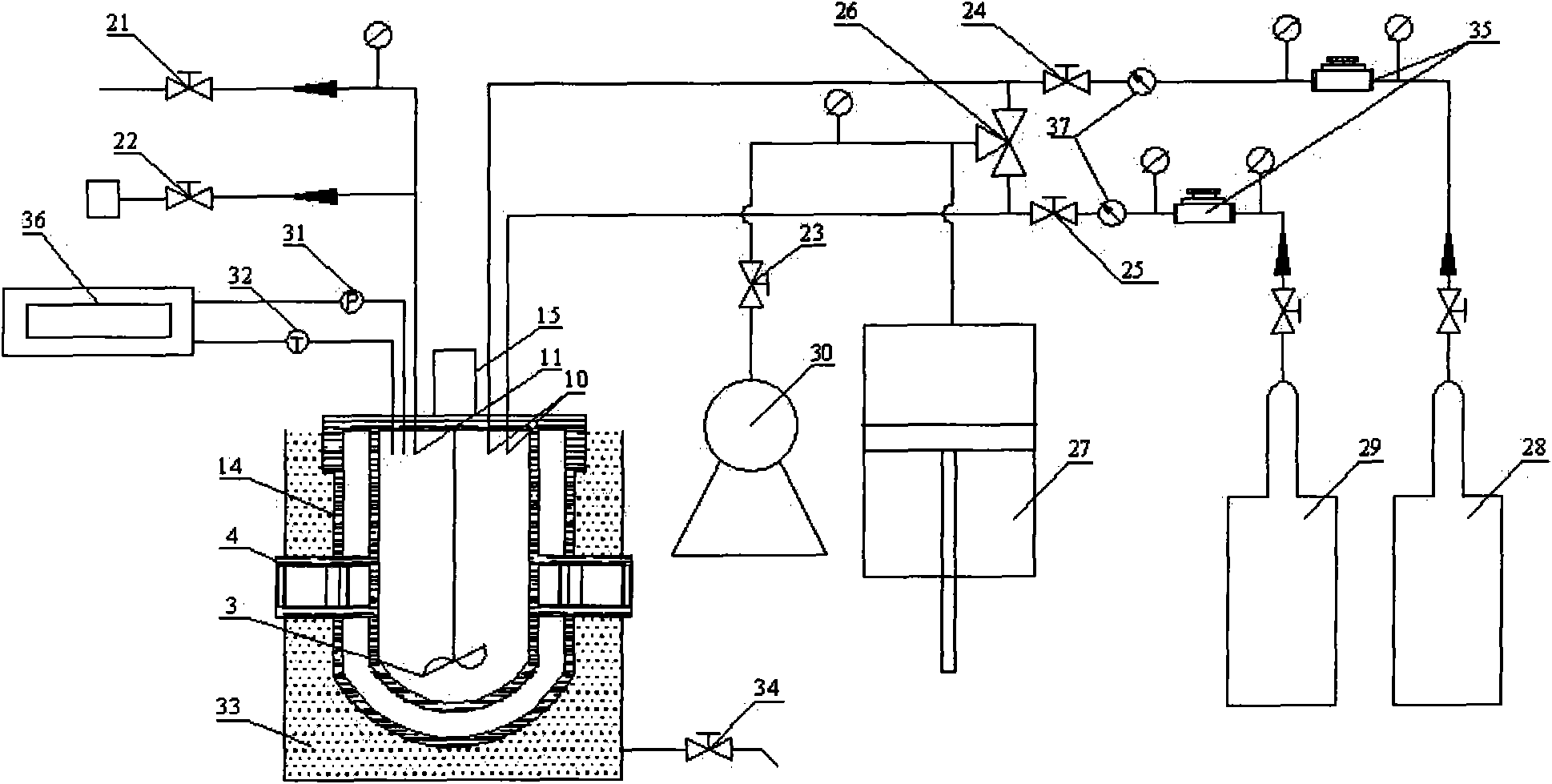

[0017] Such as figure 1 The structure schematic diagram of the low-temperature and high-pressure gas hydrate replacement reactor is shown. The low-temperature and high-pressure gas hydrate replacement reactor includes a reactor body 14, an upper end cover 7, a flange 5, a stirring device 15, a chassis 1, a pair of viewing windows 4 and several The connection port, the stirring device 15 includes a motor 13, a stirrer 16, a stirring blade 3, and a stirring shaft 18. The upper end cover 7 and the kettle body 14 are connected by a flange 5, and the space is sealed with a polytetrafluoroethylene (fluoroplastic) gasket 6 , a stirring motor 13 is installed on the central raised portion 17 of the upper end cover 7, which is a permanent magnet; a stirrer 16 is butted under the central raised portion 17 of the upper end cover 7, and it is on the same centerline as the stirring motor 13 Above, the stirring motor 13 and the stirrer 16 are connected through magnetic coupling, and the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com