Fiberglass radome modified by PE micro powder and preparation method thereof

A fiberglass radome and micropowder technology, applied in the direction of the radiation unit cover, can solve the problem of high DK value, achieve the effect of low DK value, simple preparation method, and good wave transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

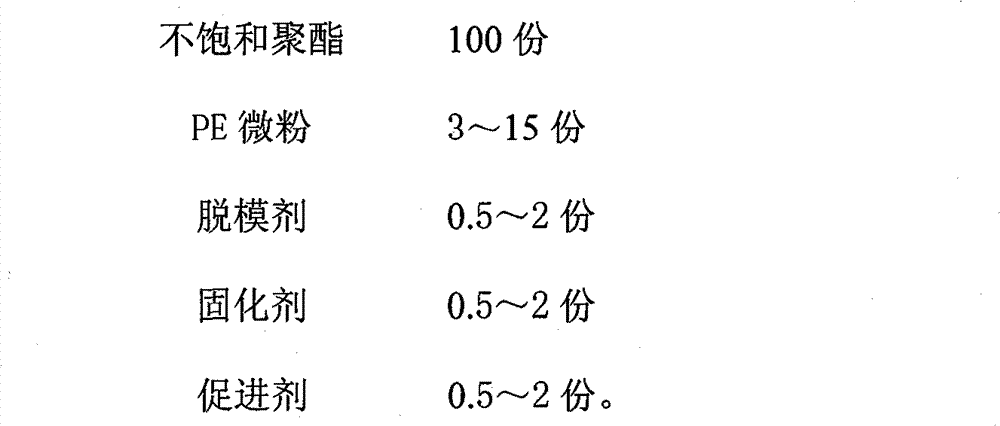

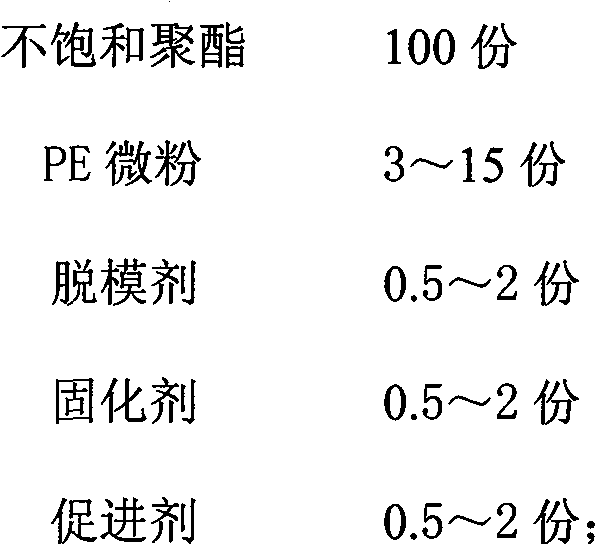

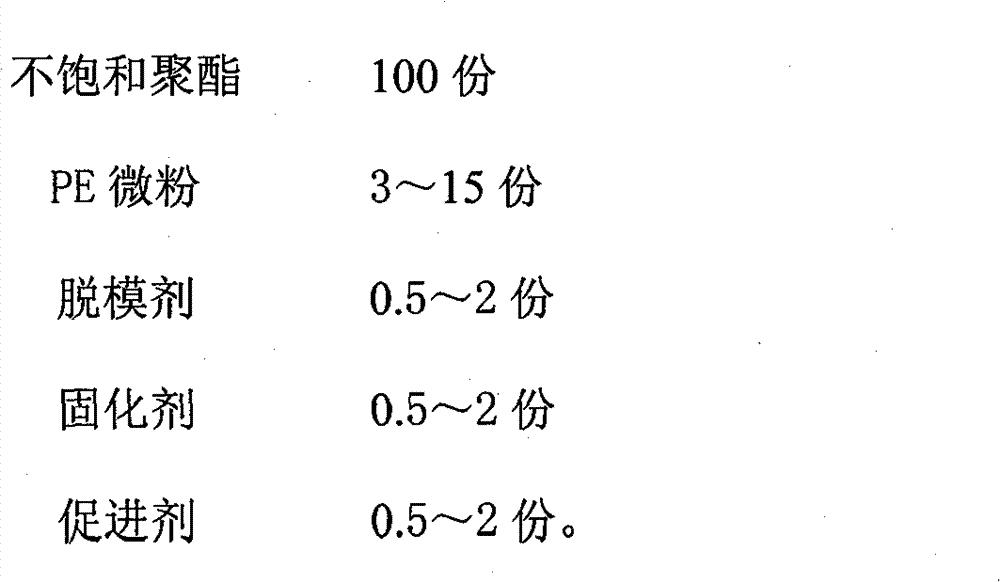

Method used

Image

Examples

Embodiment 1

[0021] Ingredients: 100kg of unsaturated polyester (A402-972), 15kg of PE micropowder, 2kg of pigment paste (RAL7035), 1kg of release agent, 1kg of curing agent, 1kg of accelerator. The dielectric constant of the tested product is shown in Table 1.

Embodiment 2

[0023] Raw material formula: 100kg of unsaturated polyester (A409-972), 12kg of PE micropowder, 2kg of pigment paste (RAL4008), 1kg of release agent, 1kg of curing agent, and 1kg of accelerator. The dielectric constant of the tested product is shown in Table 1.

Embodiment 3

[0025] Raw material formula: 100kg of unsaturated polyester (A402-902), 10kg of PE powder, 1kg of pigment paste (RAL 3011), 1kg of release agent, 1kg of curing agent, 1kg of accelerator. The dielectric constant of the tested product is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com