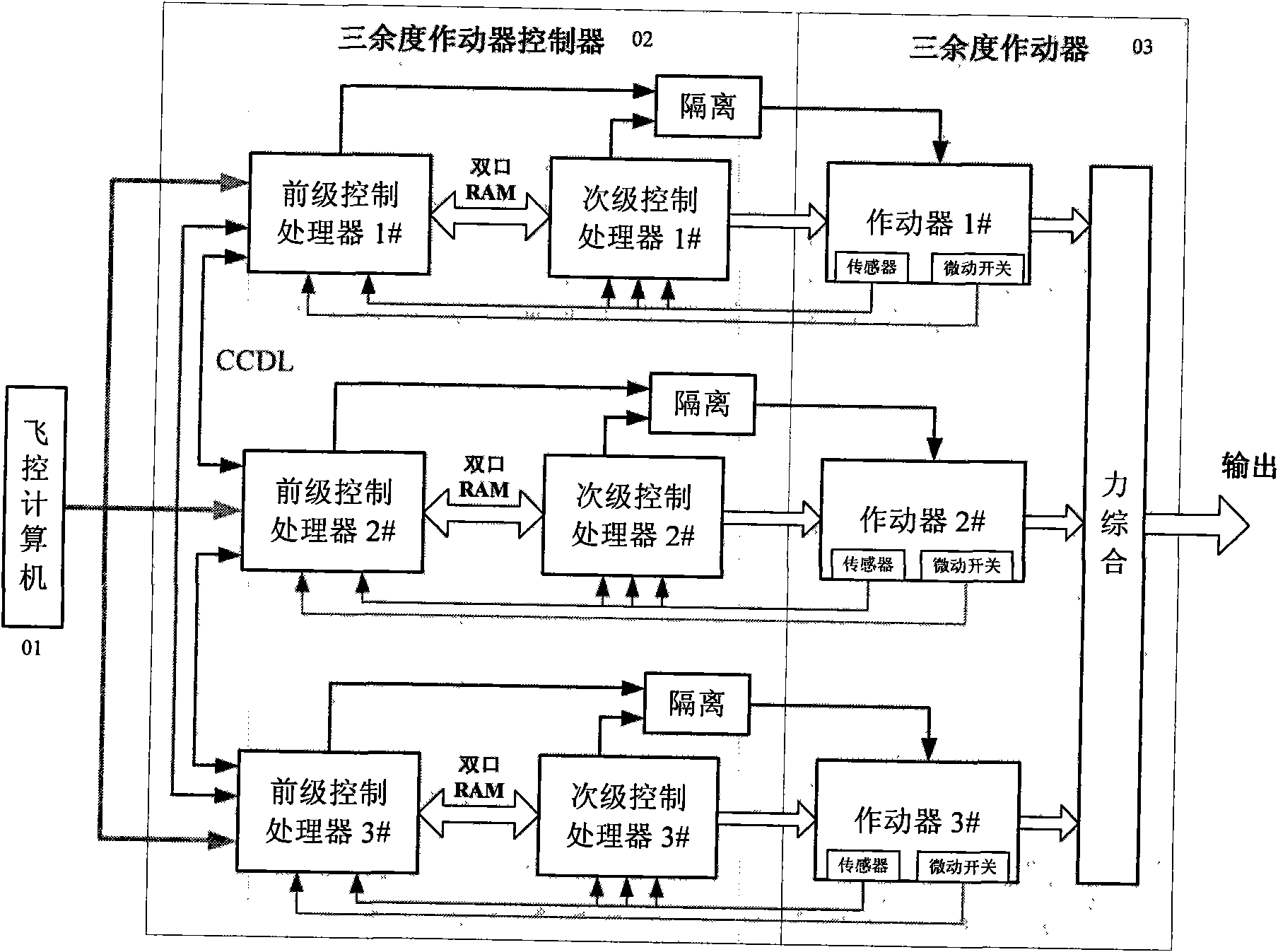

High-performance tri-redundancy steering engine based on single-channel dual-processor structure

A dual-processor, three-redundancy technology, applied in instruments, simulators, computer control, etc., can solve the problems of inability to realize the modularization of the steering gear and affecting the performance of the steering gear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

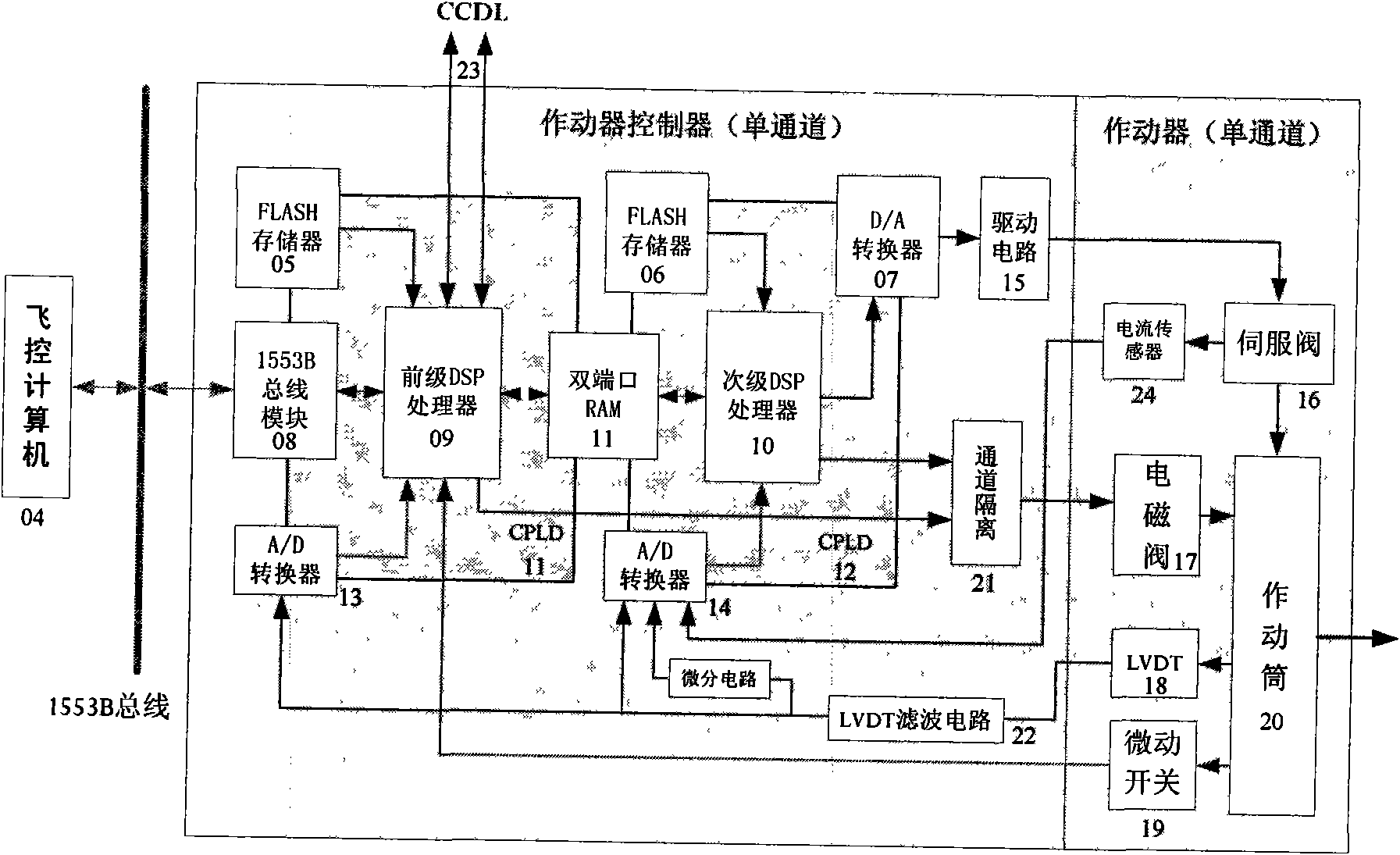

[0012] The high-performance three-redundancy steering gear should complete two tasks: closed-loop servo control and self-redundancy management. The following describes their workflow in detail.

[0013] Taking the single-channel closed-loop control as an example, the flight control computer 04 sends flight control instructions to the front-stage DSP processor 09 through the 1553B bus (or other forms of buses or communication methods); It is passed to the secondary processor 10 . The secondary processor uses the A / D converter 14 to simultaneously collect the displacement signal of the actuator, the velocity signal of the actuator and the current signal of the servo valve to perform feedback control calculations on the position loop, speed loop and current loop, and the final control value is passed through D / A converter 07 output. The driving circuit 15 converts the D / A voltage signal into the driving current of the servo valve 16 to control the movement of the cylinder 20 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com