Fuel gas generator

A gas generator and combustion system technology, applied in the direction of instrumentation, electrical program control, machine/structural component testing, etc., can solve problems such as narrow temperature and flow adjustment range, incomplete combustion of the burner, and low pressure at the hot air outlet. Achieve the effects of small temperature and flow fluctuations, complete combustion, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

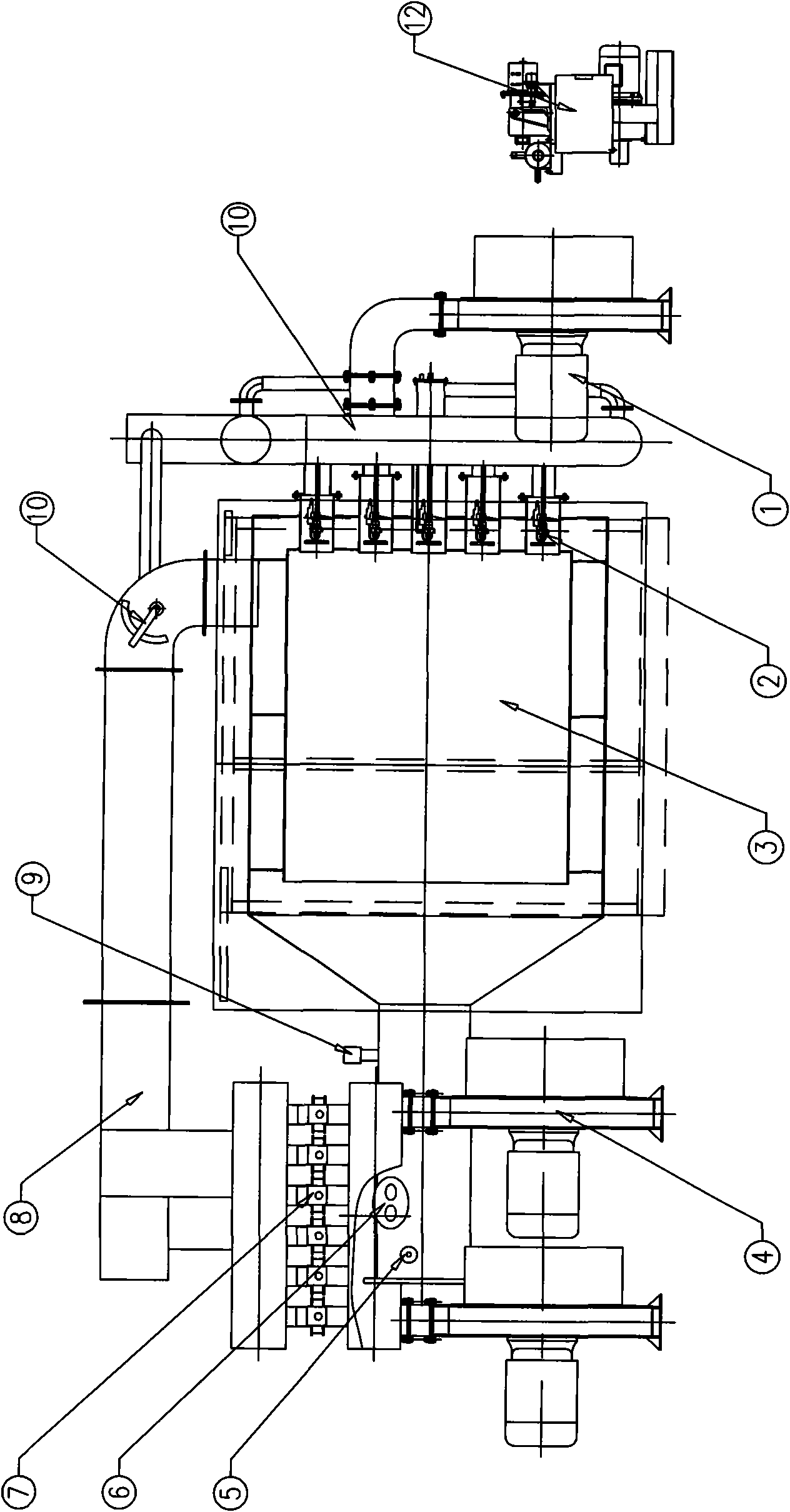

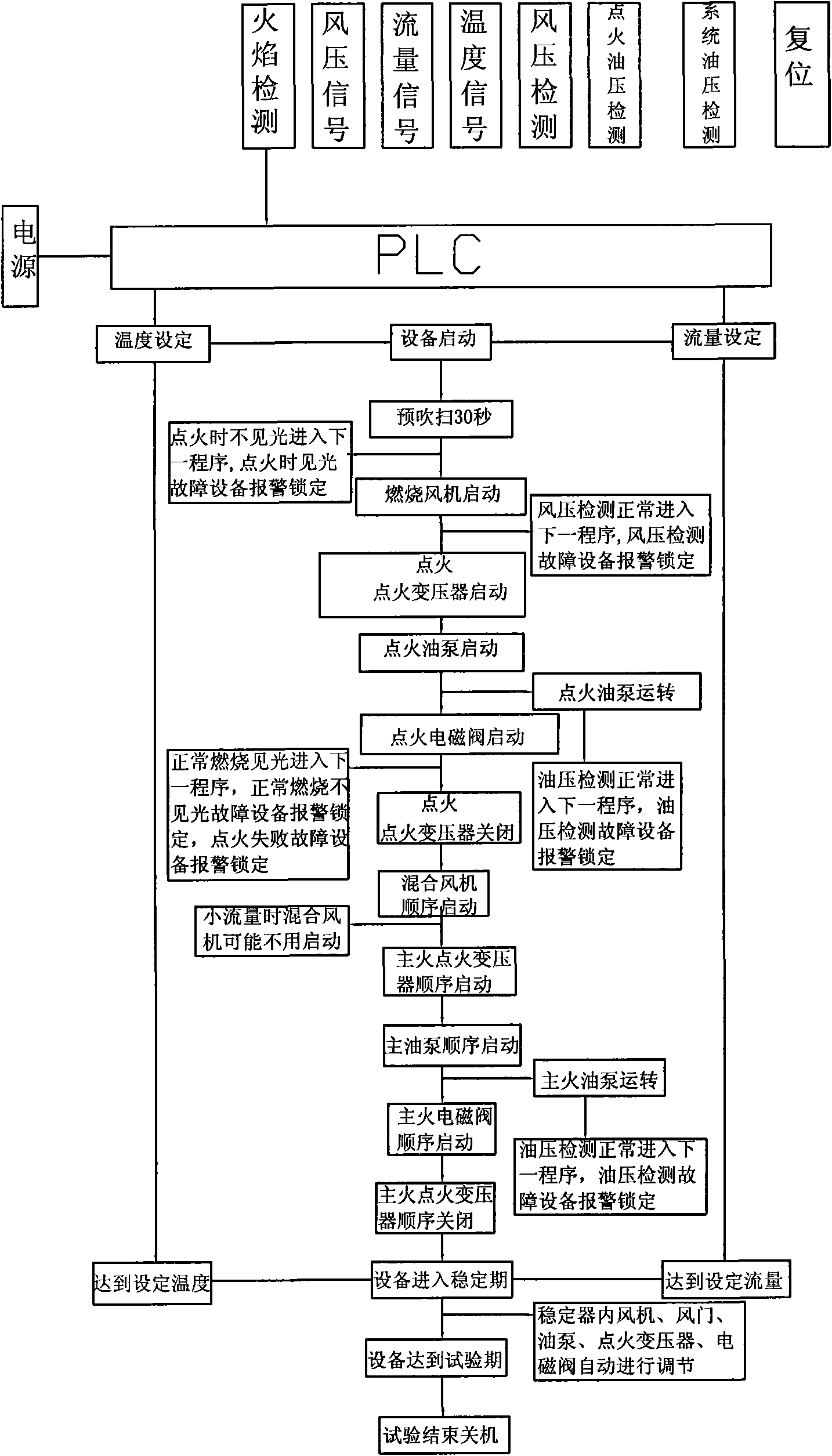

[0012] figure 1 Among them, the gas generator is composed of gas generator body 3, air supply system, combustion system, detection system, PLC control system, oil supply system and balanced air adjustment system; the air supply system is composed of combustion fan 1 and mixing fan 4 , the combustion fan 1 is connected to the gas generator body 3 through a pipeline, and the mixing fan 4 is connected to the air duct 8 of the gas generator body 3 through an electric butterfly valve 7; the combustion system is composed of a combustion spray gun 2, and the combustion spray gun 2 is installed in the gas generator On the side wall of the gas generator body 3; the detection system is composed of a flow meter 6, a pressure sensor 5 and a thermocouple 9, and the flow meter 6, the pressure sensor 5 and the thermocouple 9 are installed in the air duct 8 of the gas generator body, and the flow meter 6. The pressure sensor 5 and the thermocouple 9 are respectively connected to the PLC contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com