Decoquinate soluble powder and preparation method thereof

A decoquinate and the technology of decoquinate, applied in the field of soluble powder for livestock and poultry, can solve the problems of hindering the growth and development of chickens, failure of prevention and control, and great harm, and achieve solubility and dissolution rate acceleration, preparation The effect of simple process and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

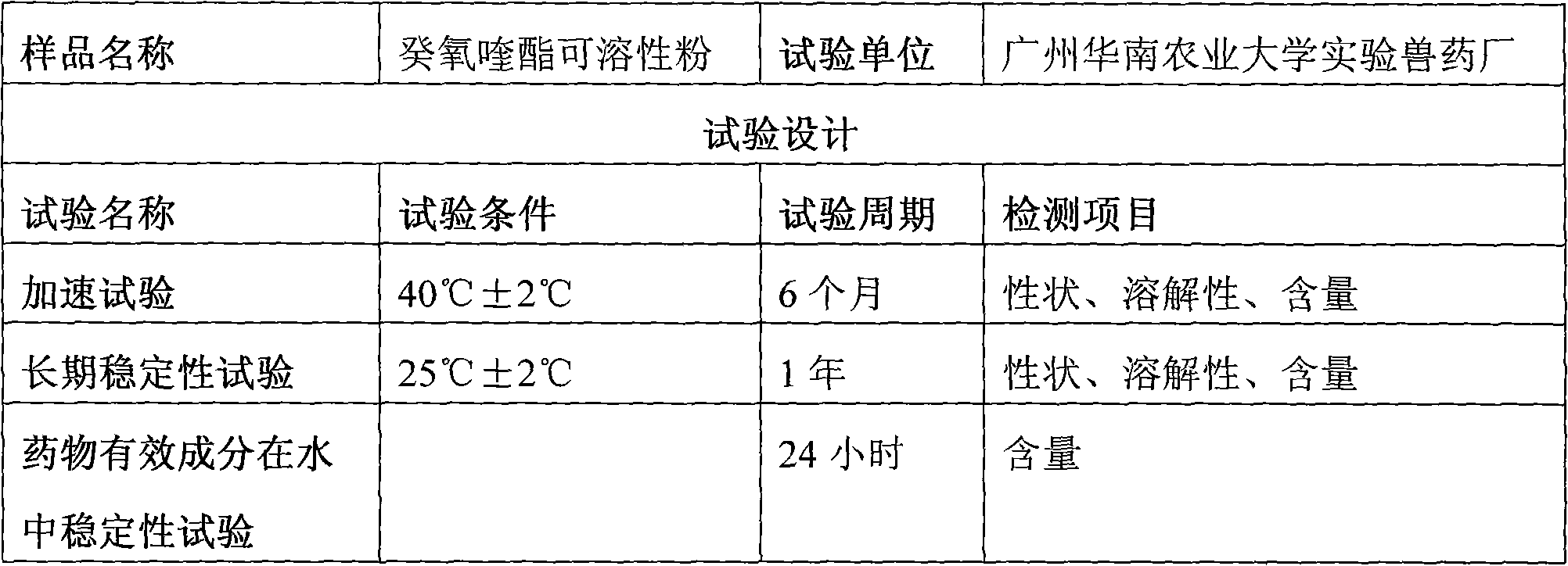

[0027] Table 1

[0028] Element

100g (total)

decoquinate

1g

polyethylene glycol 4000

1g

Polyvinylpyrrolidone K30

1g

anhydrous glucose

97g

[0029] The raw material consumption of this embodiment is as shown in Table 1.

[0030] Preparation method and steps: take crushed decoquinate raw materials, polyethylene glycol 4000, polyvinylpyrrolidone K30, mix in a mixer for 30 minutes and then take out; heat the mixed sample in an oven at 125°C for 3 hours to a molten state; take out the melt, dry it at room temperature, and pulverize it; add anhydrous glucose and mix it in a mixer for 30 minutes; subpackage and seal according to the product's loading specification, and obtain 1% (weight) decyl oxide Quincatel soluble powder.

Embodiment 2

[0032] The raw material consumption of this embodiment is as shown in table 2.

[0033] Preparation method and steps: Take the pulverized decoquinate raw material, polyethylene glycol 4000, and polyvinylpyrrolidone K30, and mix them in a mixer for 30 minutes before taking them out; heat the mixed sample in an oven at 135°C for 3 hours to Molten state; take out the melt, dry it at room temperature, and pulverize it; add anhydrous glucose and mix it in a mixer for 30 minutes; subpackage and seal according to the product’s loading specification to get 3% decoquinate soluble pink.

[0034] Table 2

[0035] Element

Embodiment 3

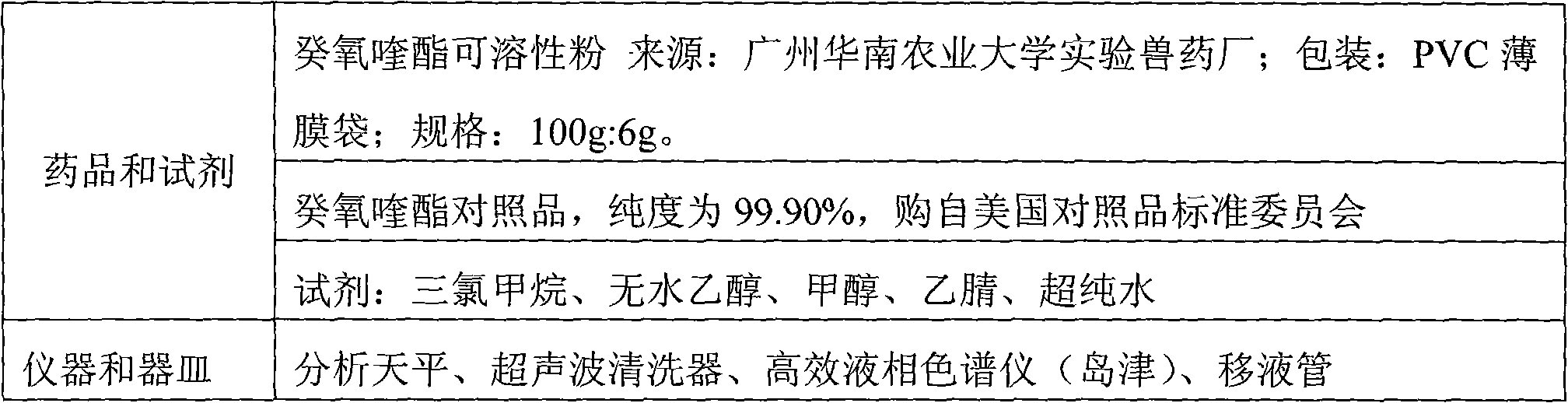

[0037] table 3

[0038] Element

100g (total)

decoquinate

6g

polyethylene glycol 6000

12g

Poloxamer 188

12g

anhydrous glucose

70g

[0039] The raw material consumption of present embodiment is as shown in table 3.

[0040] Preparation method and steps: take the pulverized decoquinate raw material, polyethylene glycol 6000, and poloxamer 188, mix in a mixer for 30 minutes and then take it out; heat the mixed sample in an oven at 130°C for 3 hours to a molten state; take out the melt, dry it at room temperature, and pulverize it; add anhydrous glucose and mix it in a mixer for 30 minutes; subpackage and seal according to the product's loading specification, and obtain 6% decoquinate Soluble powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com