Silicone tubing formulations and methods for making same

A technology of silicone and silicone polymer, which is applied in the direction of thin material processing, tubular objects, and other household appliances, and can solve problems such as short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Low molecular weight polar silicone fluids were tested as migratory additives in high consistency rubber (HCR) compound-based silicones. In this example, 5.0% by weight of 500 centipoise (cp) polyphenylmethylsiloxane (PMM-0025, obtained from Gilest Corporation) was added to a platinum-catalyzed HCR gum in an open mill. In base silicone. The resulting material was extruded into peristaltic pump tubing (0.250 inches x 0.380 inches). The pump hose was then post cured for about 1 hour in a box oven at about 177°C for about 2 hours.

[0032] In the peristaltic pump test, the tubing was evaluated using a MasterFlex pump drive (Cole Parmer) with a standard Master Flex 17 pump head designed for a tubing size of 0.250" x 0.0380". Install the hose in the pump head using the standard method proposed for Cole Parmer pumps. The tube performance was tested using water as the pump medium using a pump head speed of 600 rpm until the tube ruptured. Burst is defined as the time requi...

Embodiment 2

[0038] In this example, 0.5% by weight, 500 centipoise polyphenylmethylsiloxane (PMM-0025, obtained from Gilest Corporation) was added to platinum-catalyzed HCR-based silica in an open mill. in ketones. The resulting material was extruded into a peristaltic pump hose (0.250" x 0.380") at 40 ft / min on a Davis-Standard extruder. The product was cured in a 3 foot HAV IR oven at approximately 900-1200°F with a dwell time of approximately 4.5 seconds. The hose was post cured at about 177°C for about 2 hours and the hose was evaluated by a peristaltic pump test.

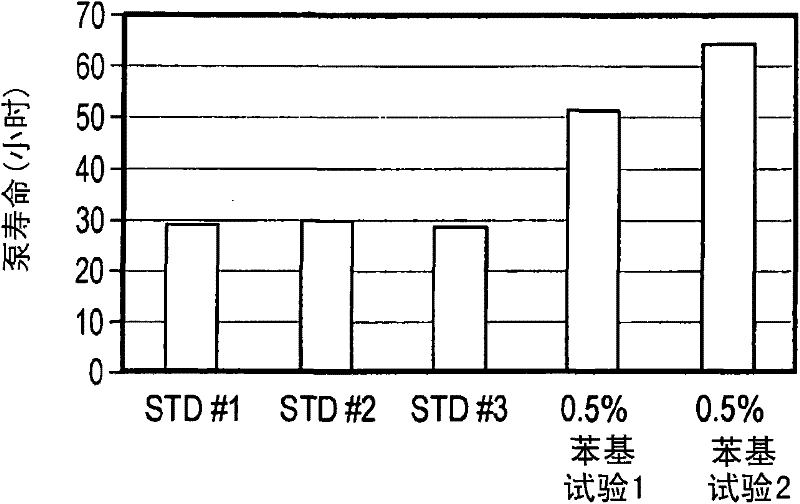

[0039] figure 2 Shown is the effect of polyphenylmethylsiloxane addition on platinum catalyzed HCR silicone lifetime. On average, the lifetime of the tubes was increased by about 100%.

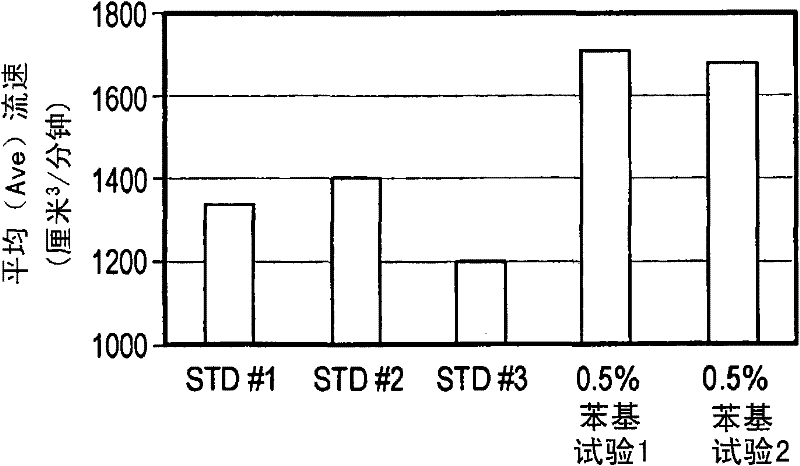

[0040] image 3 and Figure 4 The effect of polyphenylmethylsiloxane addition on flow rate consistency and target flow rate values is shown. In general, the addition of migratory components can increase the flow rate in the hose ...

Embodiment 3

[0043] A low molecular weight polar silicone fluid was tested as a mobility additive in a 50 durometer silicone rubber base. Specifically, the silicone rubber is a platinum catalyzed high consistency rubber (HCR) silicone. In this example, approximately 5.0% by weight of 500 centipoise (cp) polyphenylmethylsiloxane (PMM-0025, obtained from Gilest Corporation) was added to a platinum-catalyzed HCR rubber based silicone. The resulting material was extruded into peristaltic pump tubing (0.250" x 0.380"). The tube was then post cured for about 1 hour, about 2 hours in a box oven at about 177°C.

[0044] The materials were evaluated in unpost-cured form, post-cured form and after sterilization. Sterilization using the 60 Irradiation of γ-rays from a Co source is performed with a minimum dose of 50 kGy. The mechanical properties of the samples, such as tensile strength, flexural modulus and elongation at break, were tested on an Instron. The test procedure is in accordance wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com