Method for the preparation of high rate lithium ion capacitor battery cathode material by pyrolyzing asphalt at low temperature to cover graphite

A technology of asphalt-coated graphite and capacitor batteries, which is applied in battery electrodes, circuits, electrode manufacturing, etc., can solve the problems of poor electrical conductivity of activated carbon, long preparation cycle, and less electrode materials, and achieve fast charging and discharging, and improve charging and discharging. Efficiency, the effect of increasing the degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix ferric nitrate, distilled water and absolute ethanol uniformly in a mass ratio of 1:10:100; add graphite, pitch powder and conductive agent to the above mixed solution, wherein the added graphite is mesophase carbon microspheres, and the conductive agent is carbon black , the mass ratio added is asphalt powder:graphitization catalyst=100:1; graphite:pitch powder=2:1; conductive agent:graphite=0.3:1. Stir and mix for 5 hours, then dry the obtained mixture in the air at 80°C; carry out pyrolysis of the dried mixture under the protection of Ar atmosphere, the pyrolysis temperature is 650°C, and the holding time is 15 hours; the mass fraction is Washing with 10% nitric acid solution to remove ferric nitrate, fully washing with distilled water, and drying to obtain a negative electrode material of low-temperature pyrolysis pitch-coated graphite for high-rate lithium-ion capacitor batteries.

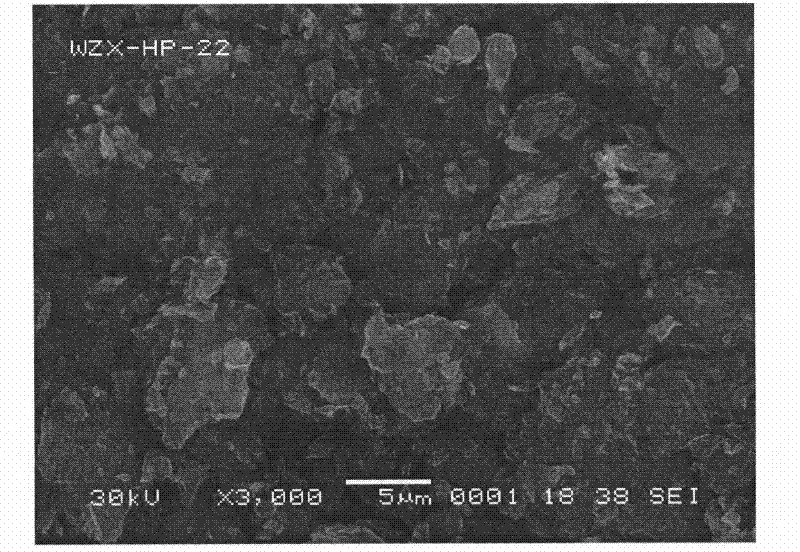

[0029] figure 1 The SEM image of the prepared low-temperature pyrolysis pitch-...

Embodiment 2

[0031] Ferric nitrate, distilled water and dehydrated alcohol are mixed uniformly by mass ratio 1: 15: 100; Add graphite, asphalt powder and conductive agent in above-mentioned mixed solution, wherein the graphite added is artificial graphite, and conductive agent is carbon nanotube, adds The mass ratio of pitch powder:graphitization catalyst=100:1; graphite:pitch powder=2.5:1; conductive agent:graphite=0.01:1. Stir and mix for 6 hours, then dry the obtained mixture in the air at 80°C; carry out pyrolysis of the dried mixture under the protection of Ar atmosphere, the pyrolysis temperature is 800°C, and the holding time is 10 hours; the mass fraction is Washing with 20% nitric acid solution to remove ferric nitrate, fully washing with distilled water, and drying to obtain a negative electrode material of low-temperature pyrolysis pitch-coated graphite for high-rate lithium-ion capacitor batteries.

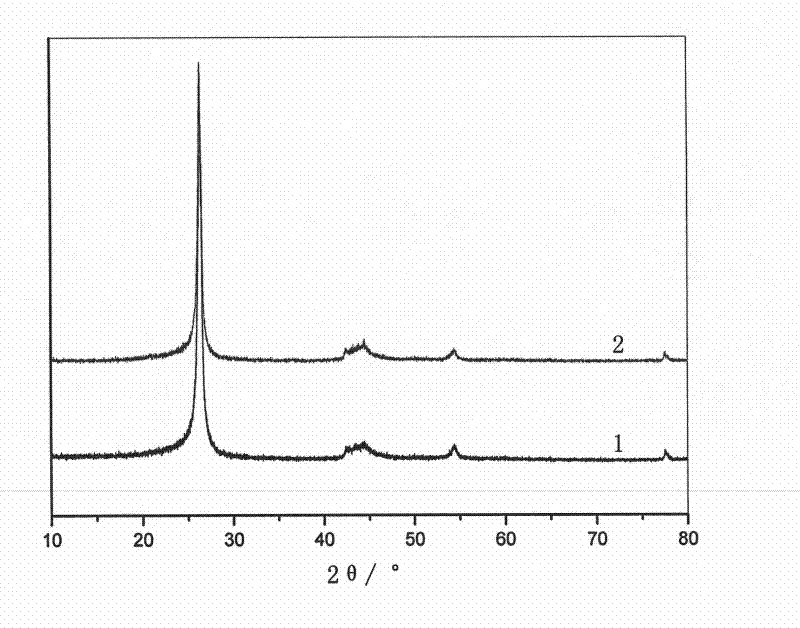

[0032] figure 2 The phase analysis results of the prepared low-temperature p...

Embodiment 3

[0035]Mix boric acid, distilled water and absolute ethanol uniformly in a mass ratio of 1:20:100; add graphite, pitch powder and a conductive agent to the above mixed solution, wherein the added graphite is natural graphite, and the conductive agent is carbon fiber. The mass ratio added For example, asphalt powder:graphitization catalyst=100:1; graphite:pitch powder=1:1; conductive agent:graphite=0.2:1. Stir and mix for 8 hours, then dry the resulting mixture in air at 80°C; dry the obtained mixture under N 2 Carry out pyrolysis under the protection of atmosphere, the pyrolysis temperature is 700 ℃, and the holding time is 12 hours; the iron nitrate is removed by washing with a nitric acid solution with a mass fraction of 15%, fully washed with distilled water, and dried to obtain a low-temperature thermal solution for a high-rate lithium ion capacitor battery. Anode material of pitch-coated graphite.

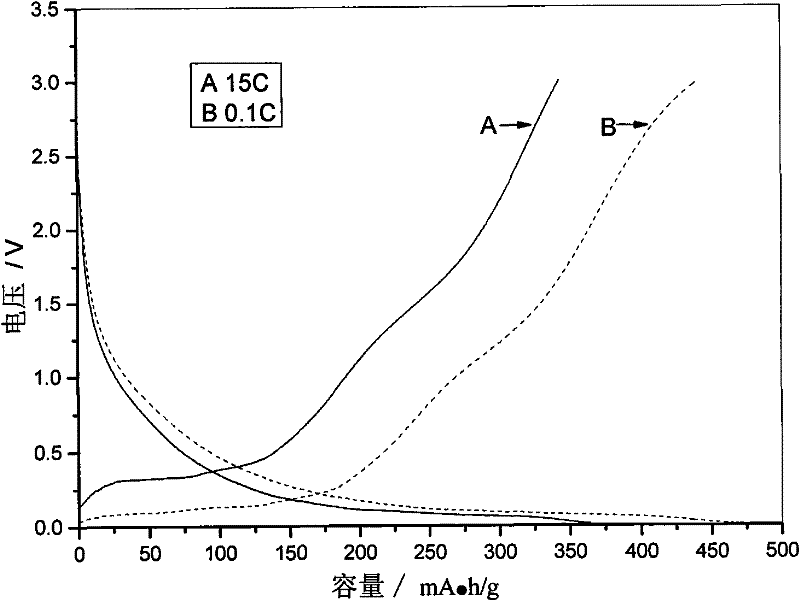

[0036] After testing, the above-mentioned low-temperature pyrolysis pitch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com