Liquid level control display instrument and using method thereof

A technology of liquid level control and display instrument, applied in liquid level control, liquid level indicator, non-electric variable control and other directions, can solve the problems of short maintenance life, high safety hazard and high cost, and achieve low cost, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

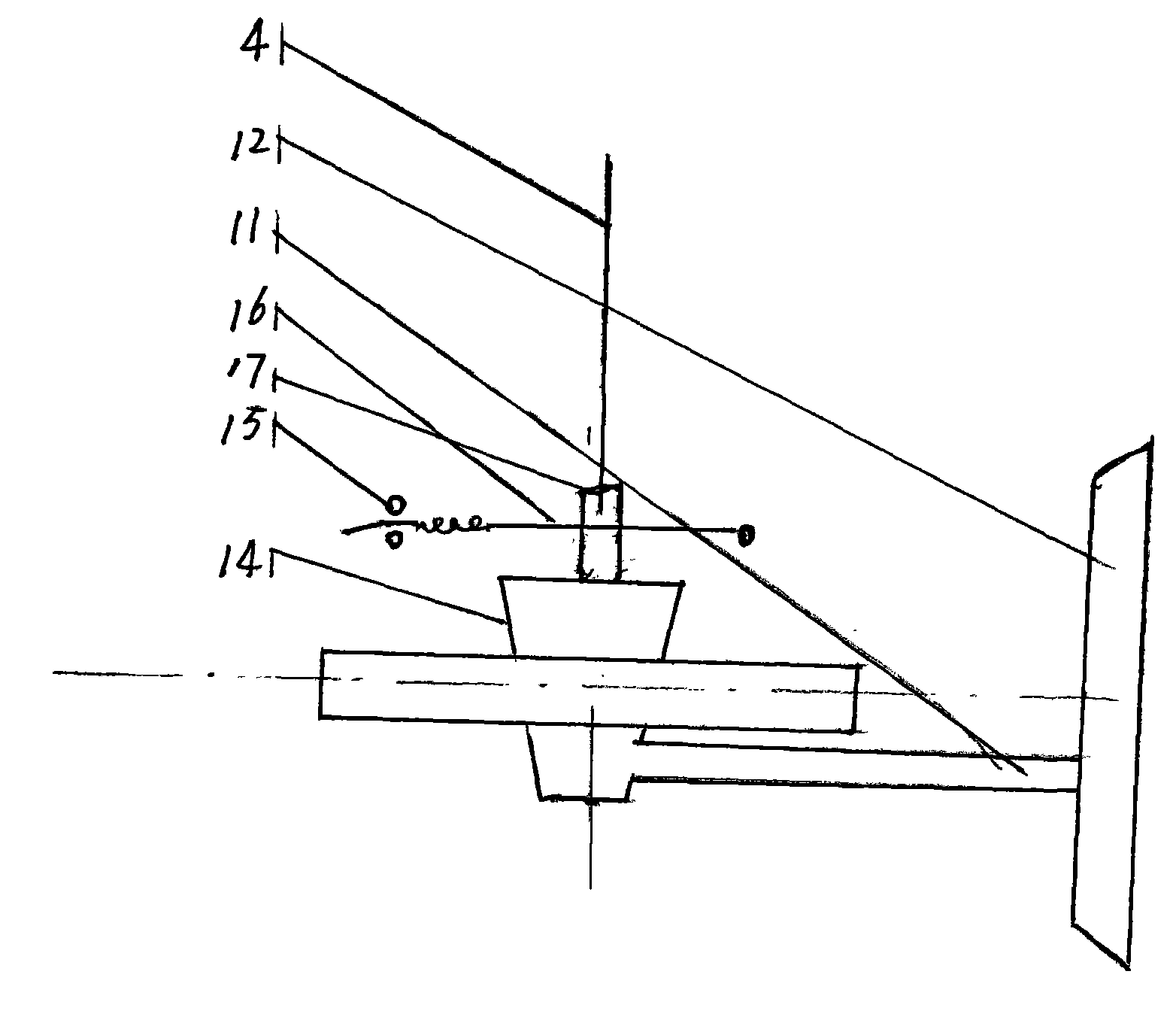

[0011] exist figure 1 , figure 2 , image 3 with Figure 4 Among them, the meter head 1 is fixed on the fixed frame 2, one end of the meter head lever 3 is connected to the inner core of the meter head 1, and the other end is connected to the transmission rod 4, the pressure adjustment spring 5 is set on the transmission rod 4 and is located above the connecting body 17, The upper end surface of the pressure adjustment cap 6 passes through the transmission rod 4 and is set on the outside of the transmission rod 4 and the pressure adjustment spring 5. There is an adjustment cavity 7 outside the pressure adjustment cap 6; The metering tube 12 is connected by the air transmission pipe 11; the travel splitting piece 16 passes through the connecting body 17, one end of the stroke splitting piece 16 is fixed on the normal contact, and the other end is located on a contact 15, and the stroke splitting piece 16 It is composed of two layers of reeds 19 inside and outside. One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com