Direct-reading dust concentration detector

A dust concentration detection, direct-reading technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as difficult to reflect objectively and truly, loss, large weighing errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

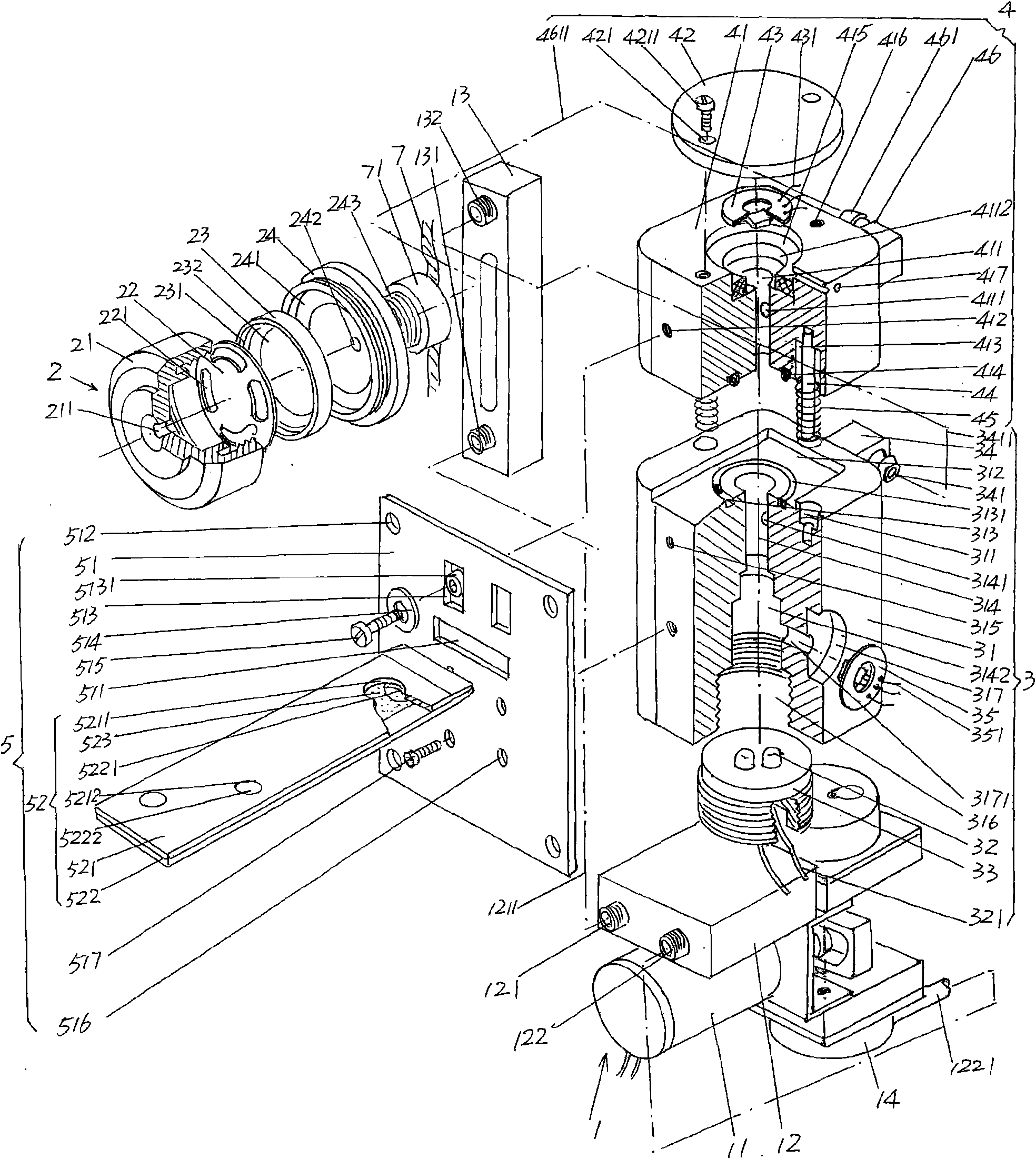

[0020] In order to enable the examiners of the patent office, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail below in conjunction with the accompanying drawings in the form of embodiments, but none of the descriptions of the embodiments is a description of the present invention. Restriction of the inventive solution, any equivalent transformation made according to the concept of the present invention which is only in form but not in substance shall be regarded as the scope of the technical solution of the present invention.

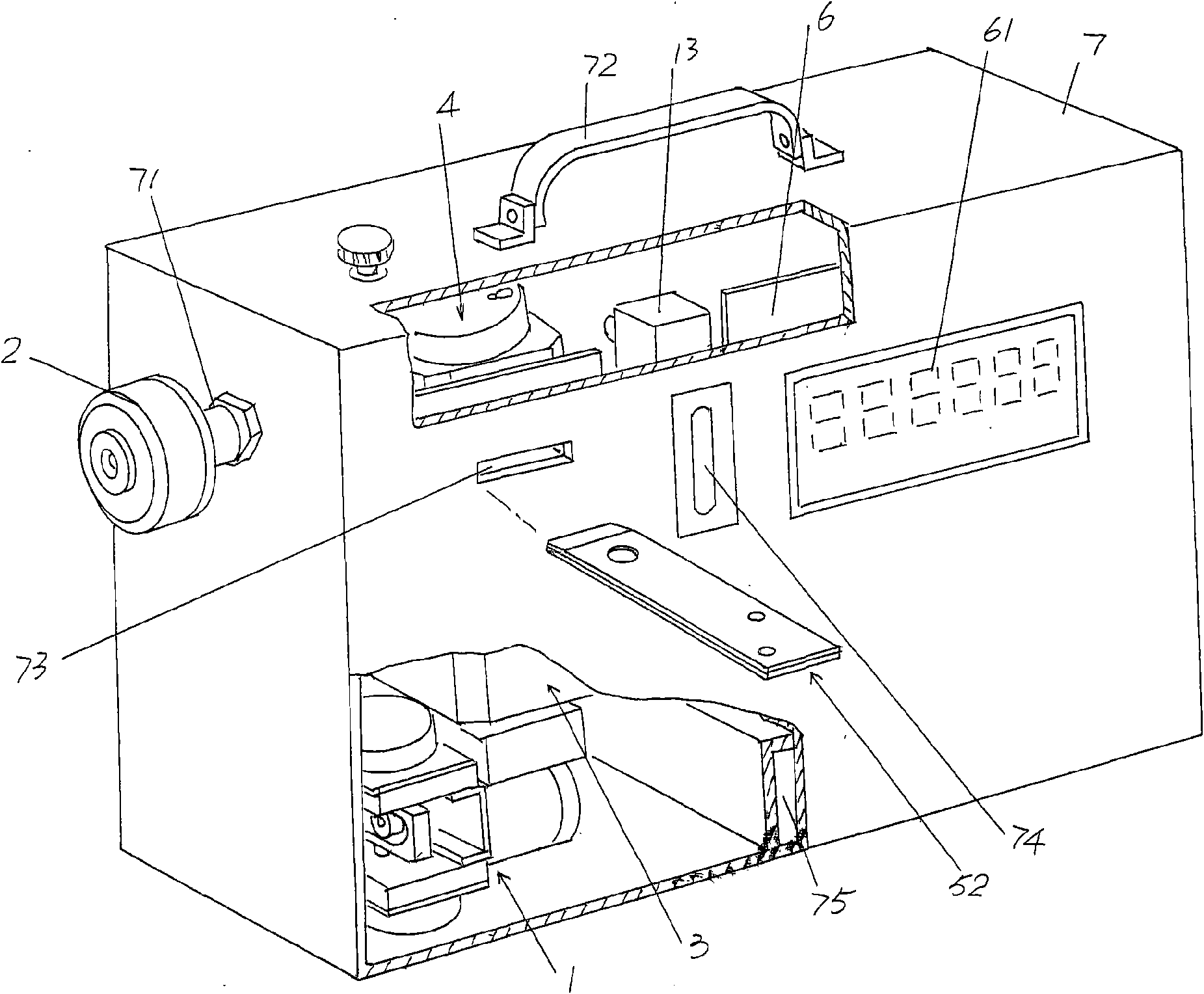

[0021] Please see figure 1 and figure 2 ,exist figure 1 The part of the box 7 is given in , while in figure 2 The overall view of the box body 7 is given in , and the handle 72 located in the middle of the upper part of the box body 7 for easy lifting, the air extraction device 1, the signal transmitting device 3, the signal receiving device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com