Biomass coal-water slurry prepared by waste leachate and domestic sludge and preparation process thereof

A technology of landfill leachate and domestic sludge, which is applied in the field of coal water slurry, can solve problems such as failure of the treatment system, high investment and operation costs, and overall urban pollution, so as to reduce the difficulty and pressure of treatment, solve the problem of raw materials for production, and solve the problem of The effect of energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

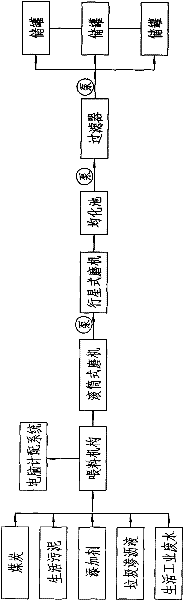

Image

Examples

Embodiment 1

[0024] The biomass coal-water slurry prepared from landfill leachate and domestic sludge of the present invention comprises the following components by weight percentage:

[0025] Coal 40% Domestic sludge 20%

[0026] Landfill leachate 39.7% additive 0.3%.

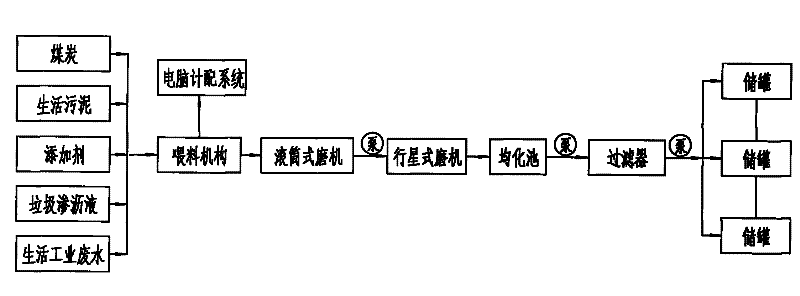

[0027] The preparation process of the biomass coal-water slurry prepared from the above-mentioned garbage leachate and domestic sludge is as follows: the above-mentioned percentage of coal and domestic sludge are transported to the feeding mechanism, and at the same time, the computer metering system is used to measure and add the garbage leachate Mix liquid and additives, and then carry out primary grinding and crushing by the drum mill. After melting, it is filtered through a filter, and the finished coal water slurry is obtained after filtration, which is loaded into a storage tank.

[0028] The drum mill for primary crushing is configured with two compartments, and is responsible for coarse crushing of materials to b...

Embodiment 2

[0034] In the present embodiment, the biomass coal-water slurry prepared from the landfill leachate and domestic sludge comprises the following components by weight percentage:

[0035] Coal 42% Domestic sludge 18%

[0036] Landfill Leachate 20% Additive 0.4%

[0037] Domestic and industrial wastewater 19.6%.

[0038] Compared with Example 1, in this implementation, domestic and industrial wastewater is added as production supplementary water, and the domestic and industrial wastewater can be production flushing water, canteen wastewater, domestic sewage and rainwater.

[0039] The preparation process of the biomass coal-water slurry prepared from the above-mentioned garbage leachate and domestic sludge is as follows: the above-mentioned percentage of coal and domestic sludge are transported to the feeding mechanism, and at the same time, the computer metering system is used to measure and add the garbage leachate Liquid, domestic and industrial wastewater and additives are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com