Trace oil igniting coal dust firing device for multiple oil guns

A technology of pulverized coal combustion and small amount of oil, applied in the direction of burner, combustion ignition, combustion method, etc., can solve the problems of large distance, no staggered setting of main oil gun and auxiliary oil gun on the opposite side, ignition failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

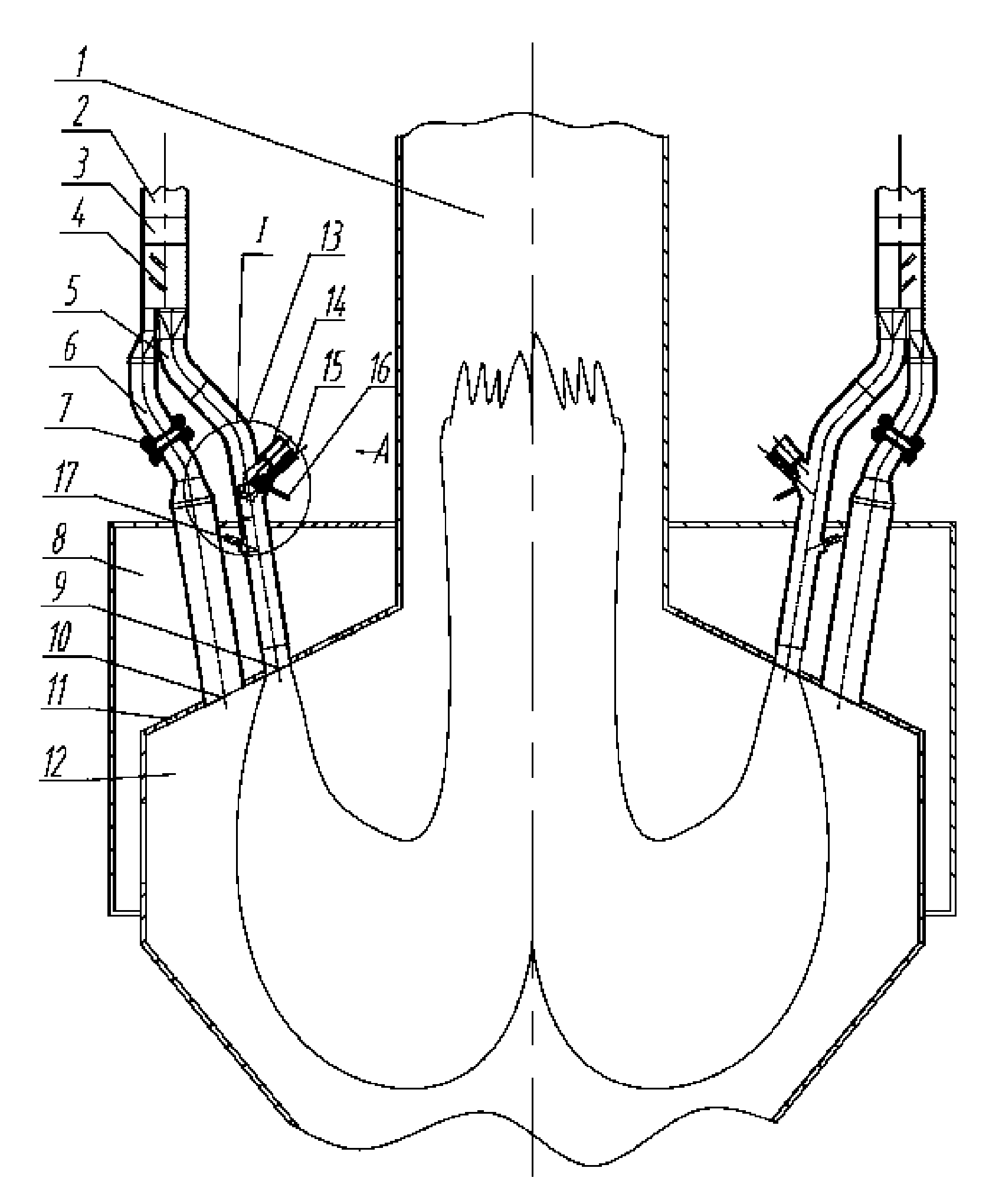

[0010] Specific implementation mode one: combine Figure 1~3 , Figure 4a~4b Describe this embodiment mode, a kind of pulverized coal combustion device described in this embodiment mode includes a primary air duct 2, a grid divider 3, a pulverized coal thick-lean separator 4, and two pipelines for dense pulverized coal 5. Light coal powder pipeline 6, light coal powder pipeline baffle plate 7, fire inspection piece 16, two main oil guns 14, two auxiliary oil guns 15 on the same side and two auxiliary oil guns 17 on the opposite side; the grille The inlet end of the equalizer 3 is connected to one end of the primary air duct 2, and the coal dust separator 4 is arranged inside the grid equalizer 3, and the outlet end of the grid equalizer 3 is respectively connected to two dense coal dust pipelines 5 The inlet end of the light pulverized coal pipeline 6 is connected, and the outlet ends of the two thick pulverized coal pipelines 5 and the outlet ends of the light pulverized coa...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 1~3 , Figure 4a~4b Describe this embodiment, the distance between the intersection of the centerline of the main oil gun 14 and the centerline of the auxiliary oil gun 15 on the same side and the centerline of the thick pulverized coal pipeline 5 in this embodiment is L is 90-95mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 with image 3 Describe this embodiment, the distance M between the centerline of the main oil gun 14 and the centerline of the auxiliary oil gun 17 on the opposite side and the centerline of the thick pulverized coal pipeline 5 in this embodiment is 600-650mm. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com