Expanding cabin floor board lifting device

A lifting device and expansion cabin technology, applied in the field of floor lifting devices, can solve the problems of inconvenient equipment, appliance fixing, installation and use, inconvenient personnel movement, large cabin space, etc., and achieve the effect of compact structure, easy manufacture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

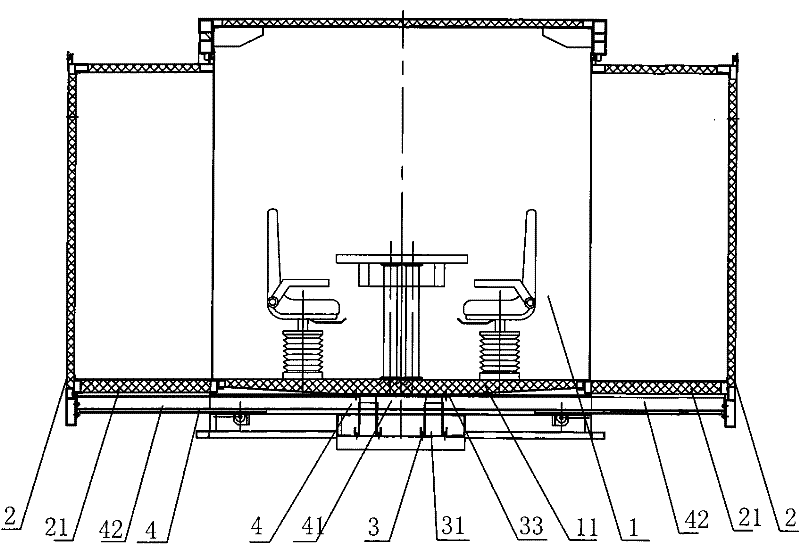

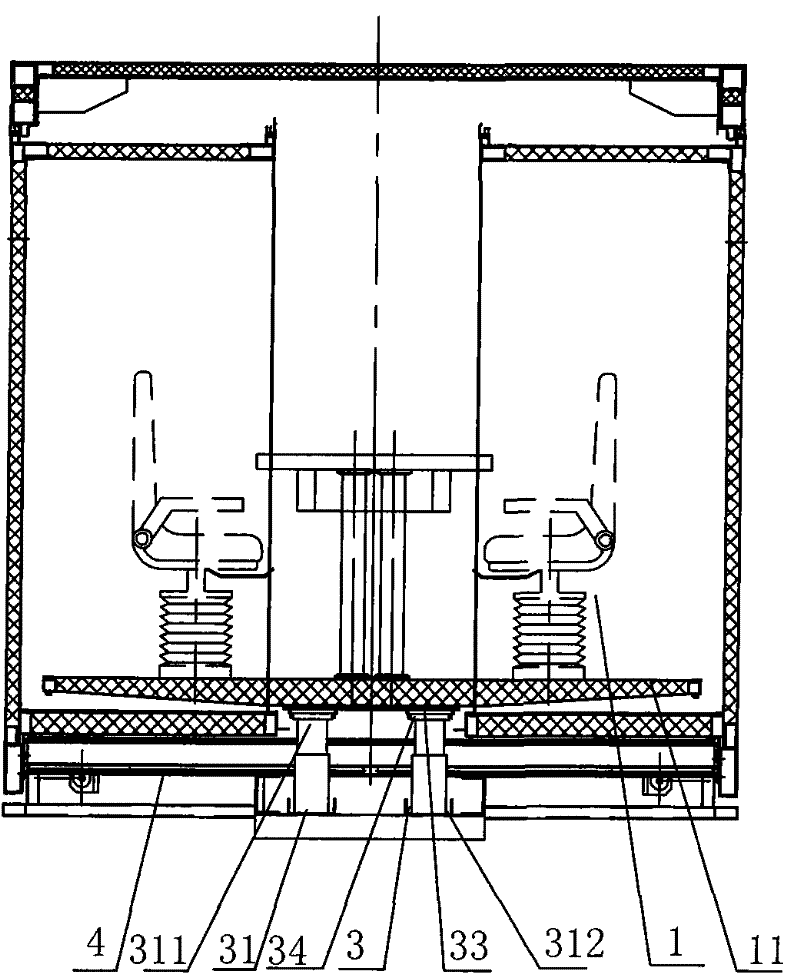

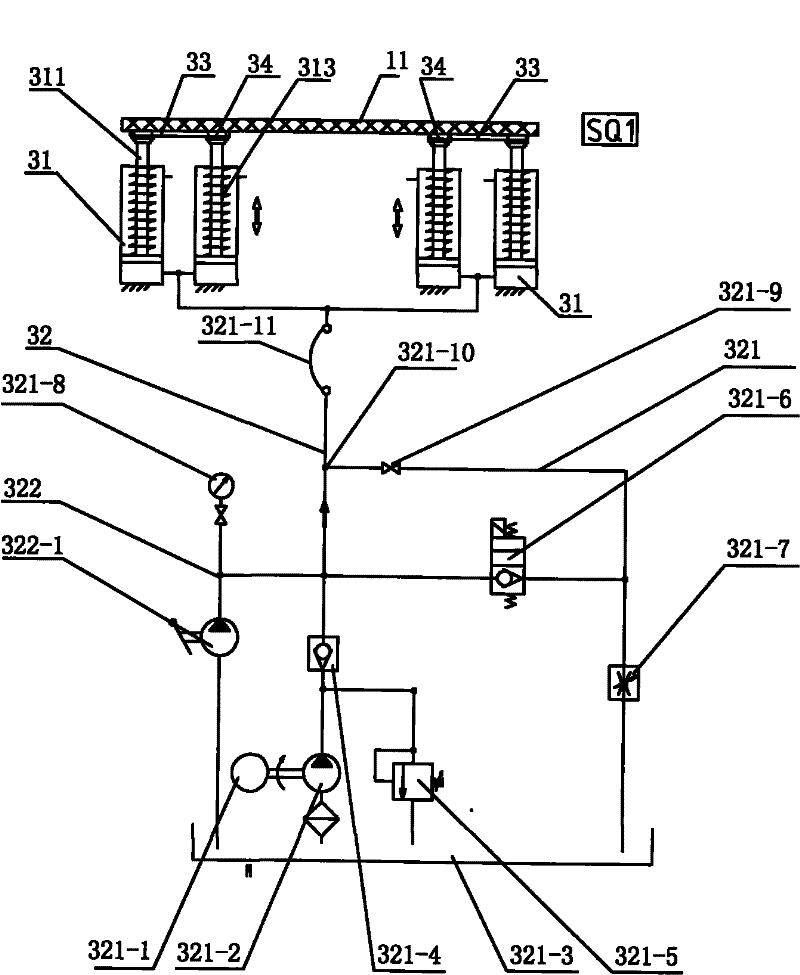

[0016] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a main cabin body 1, a side cabin body 2 that is sleeved on both sides of the main cabin body 1, a main cabin body floor lifting mechanism 3 and a side cabin body floor telescopic mechanism 4. The main cabin body floor 11 is floatingly installed below the main cabin body 1, and the side cabin body floors 21 are respectively fixed at the bottom of both sides of the cabin body. Lifting mechanism 3 is arranged on the below of main cabin body floor 11, and this main cabin body floor lifting mechanism 3 comprises 2 pairs of lifting oil cylinders 31, hydraulic drive system 32, 2 synchronous connecting plates 33, flange 34; Restricted, the lifting cylinders 31 of the present embodiment are vertically arranged in pairs at both ends of the main cabin floor 11 in the longitudinal direction, and a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com