Rotary filter for purifying fusant of plastic extrusion system

A rotary filter and melt purification technology, applied in the field of melt purification filters, can solve the problems of poor work efficiency, fusion medium barrier, waste of production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

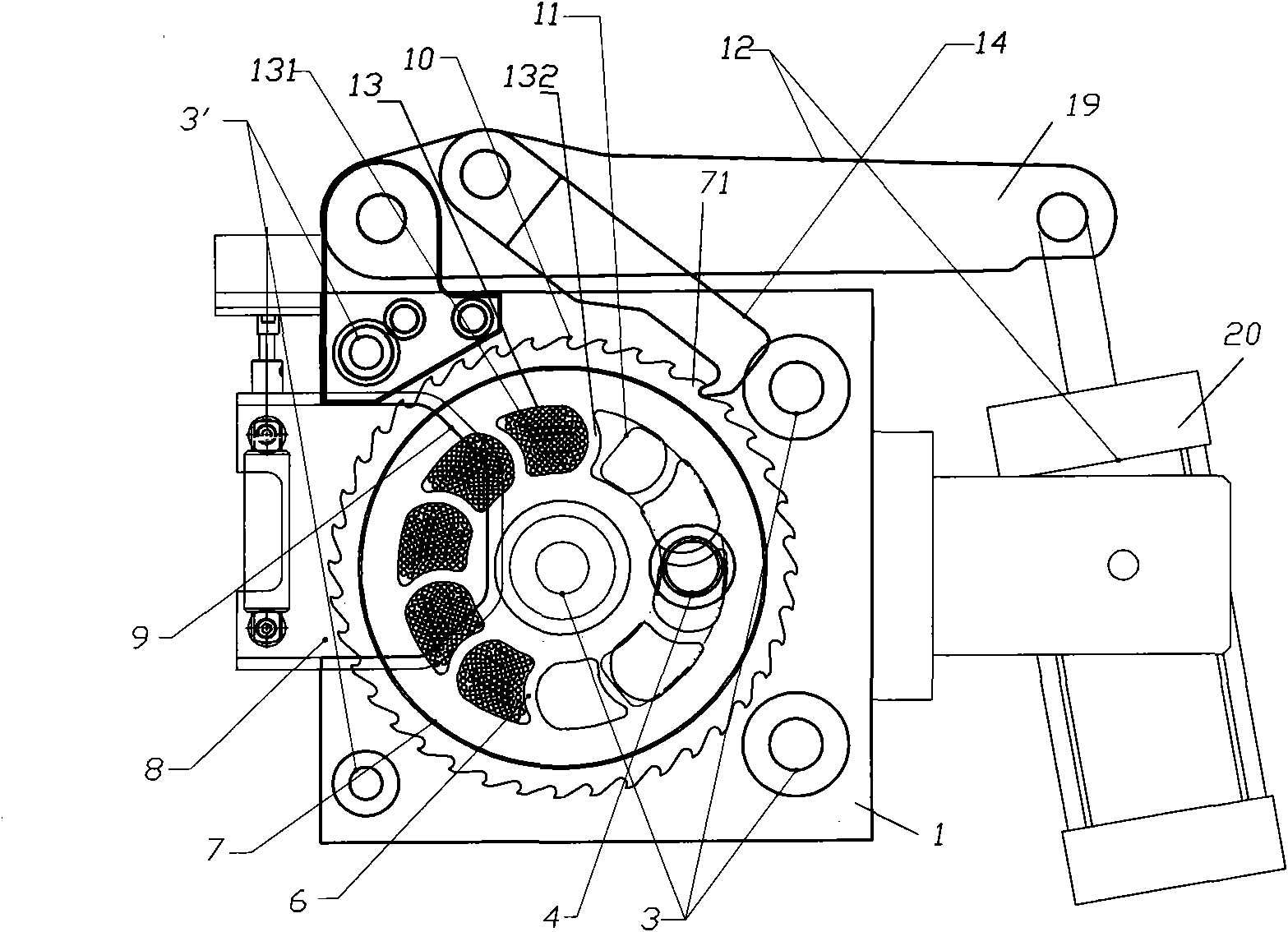

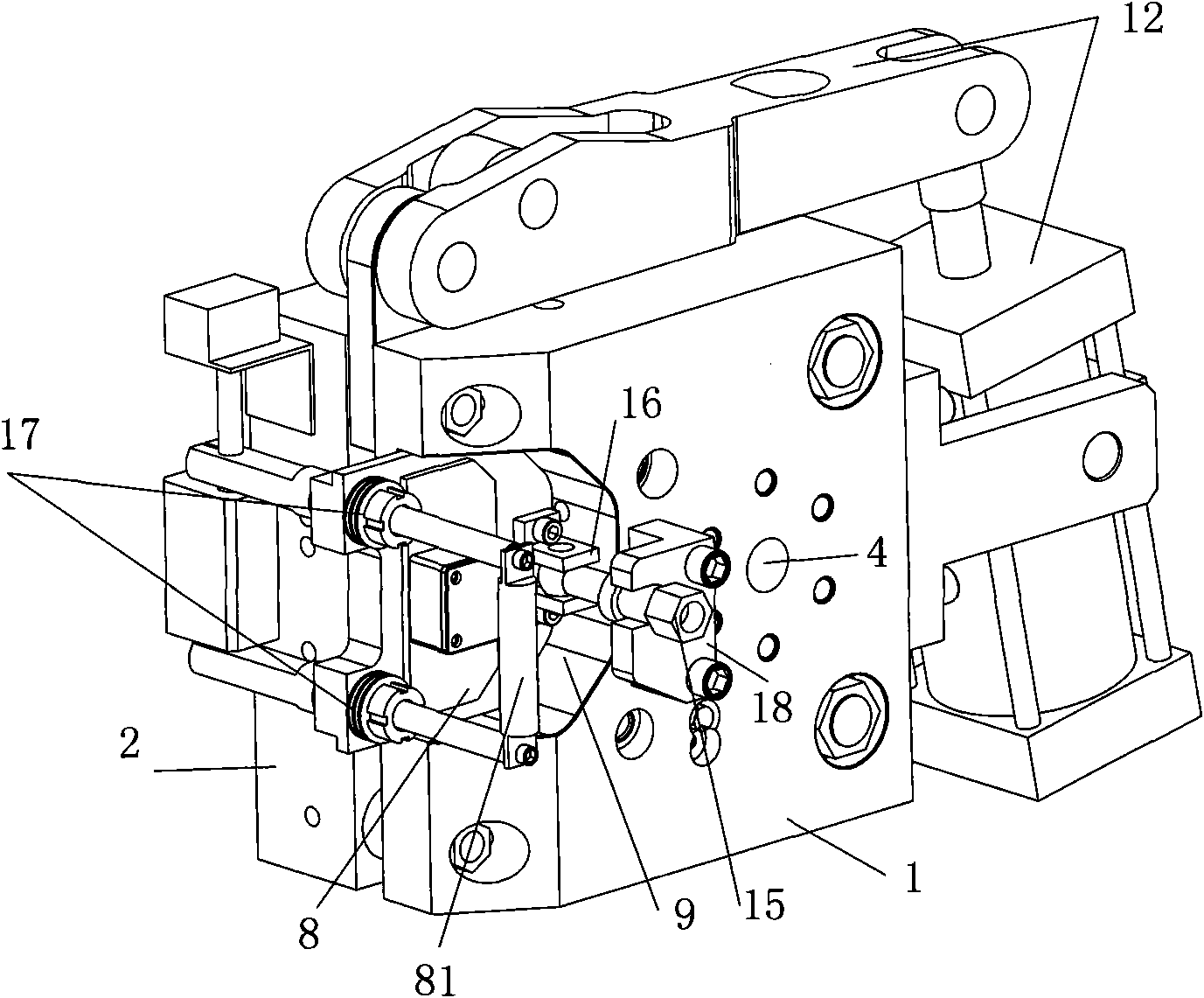

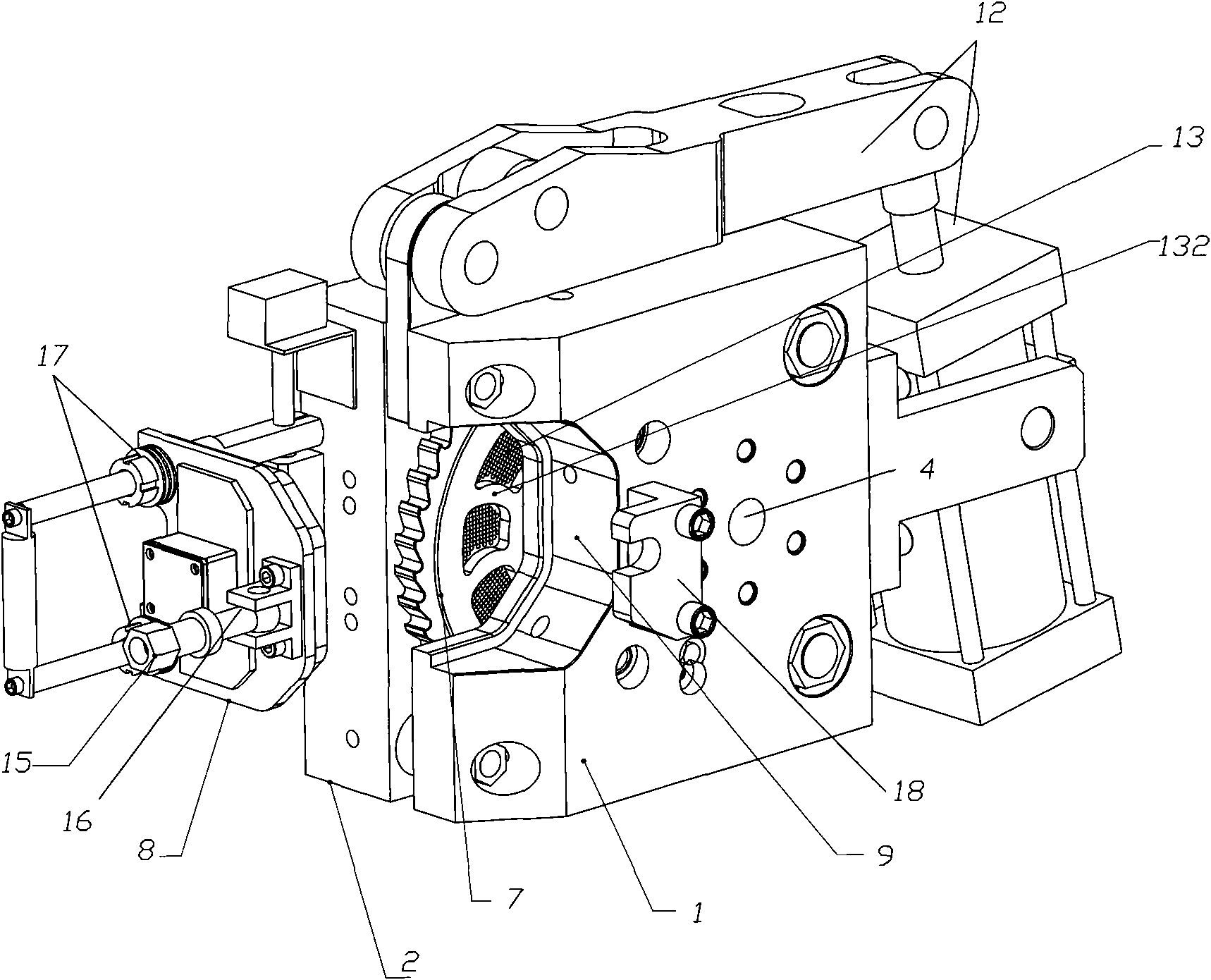

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] Such as figure 1 , 2 , 3, the rotary filter used for plastic extrusion system melt purification has a feed end body 1 and a discharge end body 2, and the filter mesh disc 7 is arranged on the feed end by connecting fastening elements 3, 3' Between the body 1 and the body 2 at the discharge end, the filter disc 7 is tightly covered by the body 1 at the feed end and the body 2 at the discharge end. A door body 8 that can open or lock the screen changing room is provided. The screen changing chamber 9 is arranged on the left side of the feeding direction of the feed end body 1, and the area of the screen changing chamber 9 is greater than the area of 2 filter mesh holes 13 and the two wall panels 132 and less than 3 filter mesh holes 13 and the two wall panels. The area of a wall panel 132. The door body 8 is provided with a locking device 16, and the locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com