Upright post structure of horizontal type numerical control boring-milling machine

A boring and milling machine and column technology, which is applied in the field of horizontal CNC boring and milling machines, can solve the problems of high structural strength requirements of columns, concentrated load-bearing, poor stability of single hammer structure, etc., and achieve low manufacturing cost, uniform load-bearing and reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

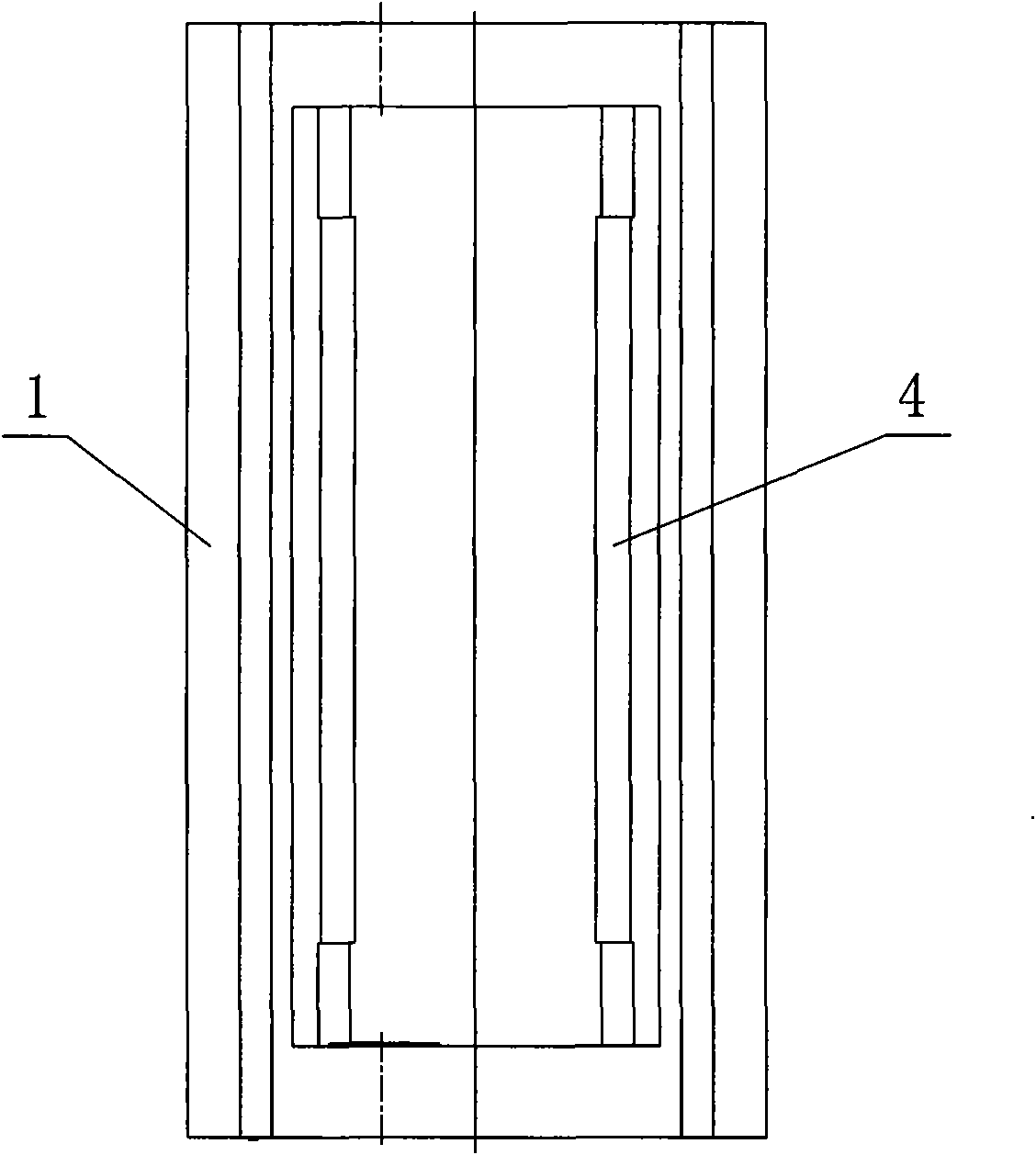

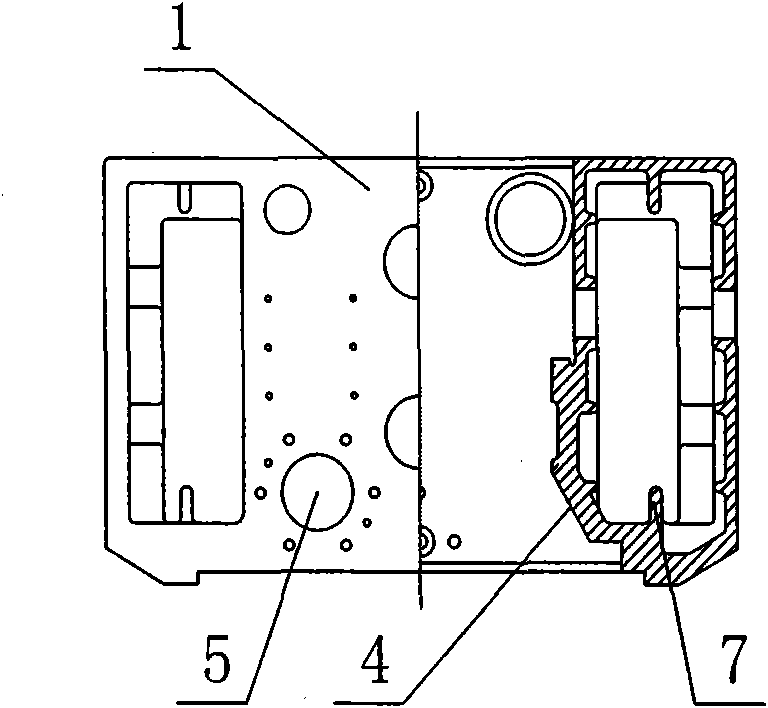

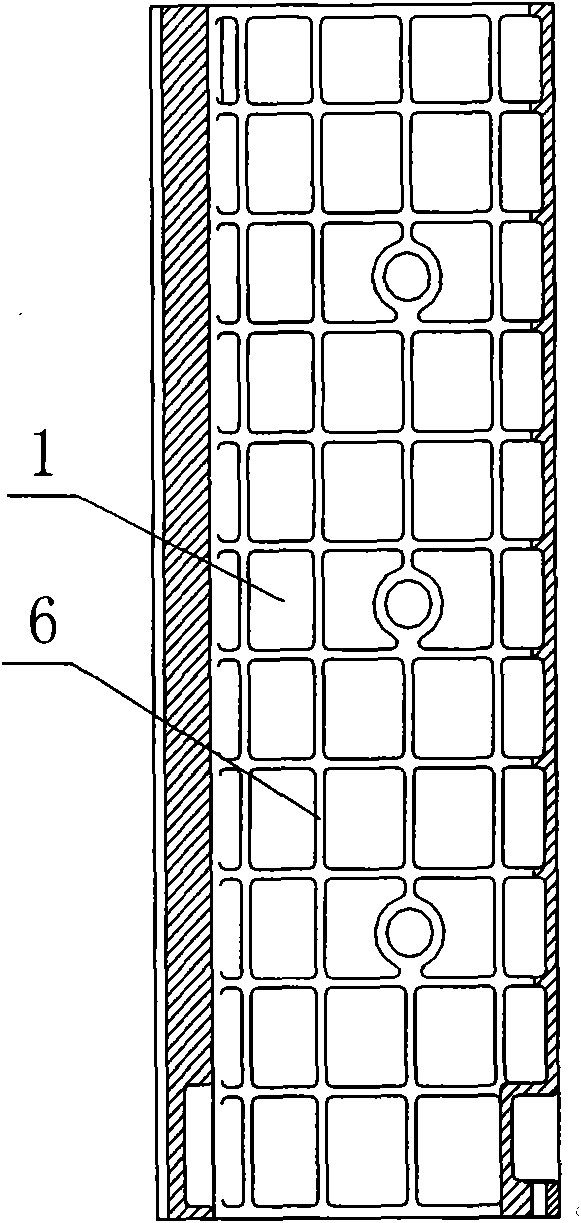

[0021] Such as figure 1 As shown, the column structure of the horizontal CNC boring and milling machine according to the present invention includes a column 1, a pulley frame 2 installed on the column 1, and a counterweight 3. The column 1 is integrally formed and adopts a gantry frame type setting. There is a V-shaped guide rail 4 connected with the slider 9, and the top beam of the column 1 is provided with a screw hole 5, and the screw hole 5 is installed with a screw for driving the slider to move along the guide rail; the column is hollow, In addition, a number of reinforcing ribs 6 are provided on the inner side of the column; the counterweight 3 is a double hammer structure, and the counterweight 3 and the slider 9 are hoisted on the pulley frame; the two counterweights of the counterweight 3 are placed separately In the hollow position inside the column body of the column 1, a guide rail 7 is provided inside the column body, and a track groove 8 cooperating with the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com