Double welding torch direct-current arc welding and power generation machine

A technology of DC arc welding and double welding torches, applied in the direction of synchronous generators, etc., can solve the problems of complex manufacturing process, many reactor taps, and easy failures, and achieve the effects of improved stability, small voltage change rate, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is based on Figure 1 to Figure 3 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

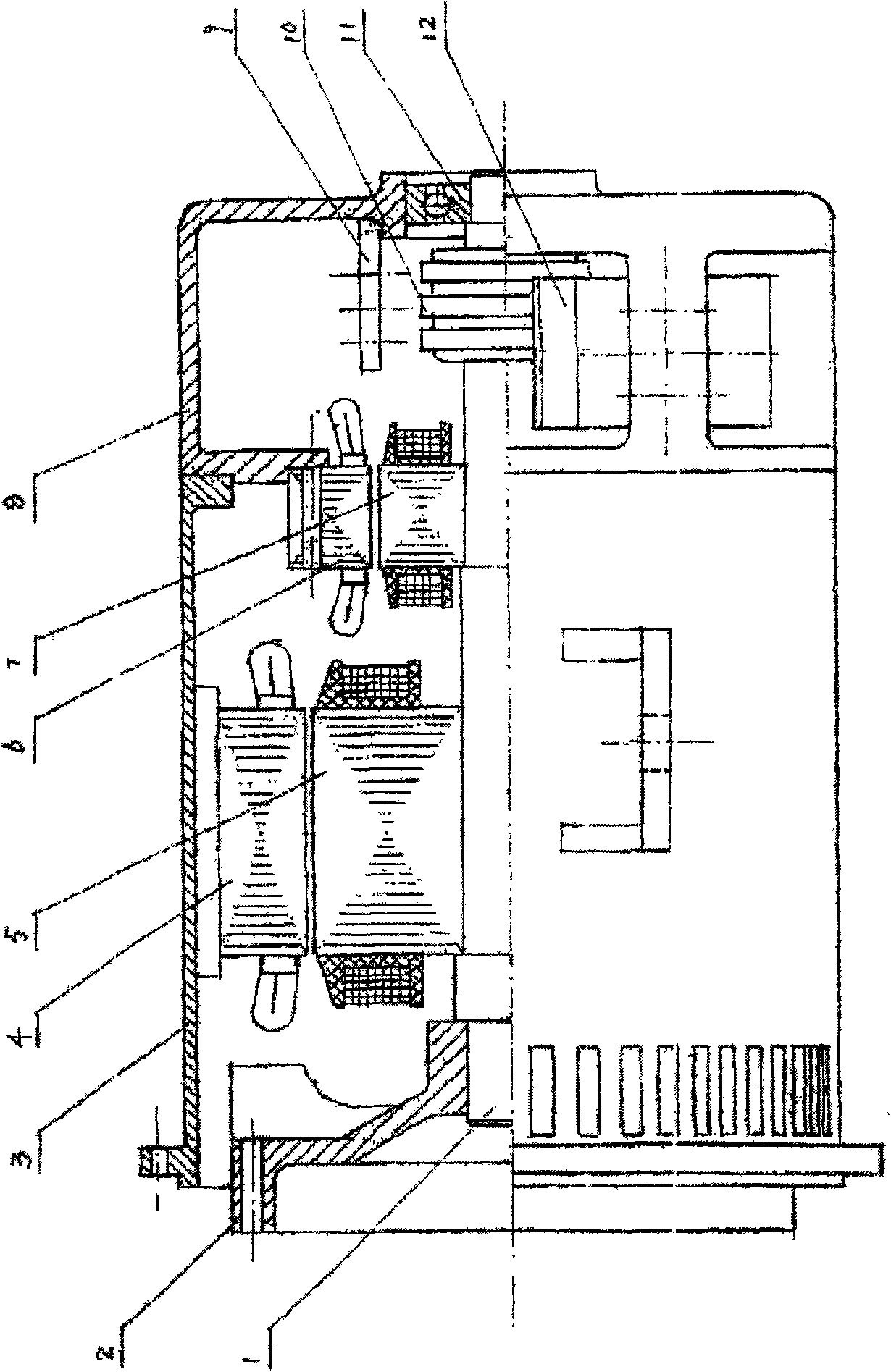

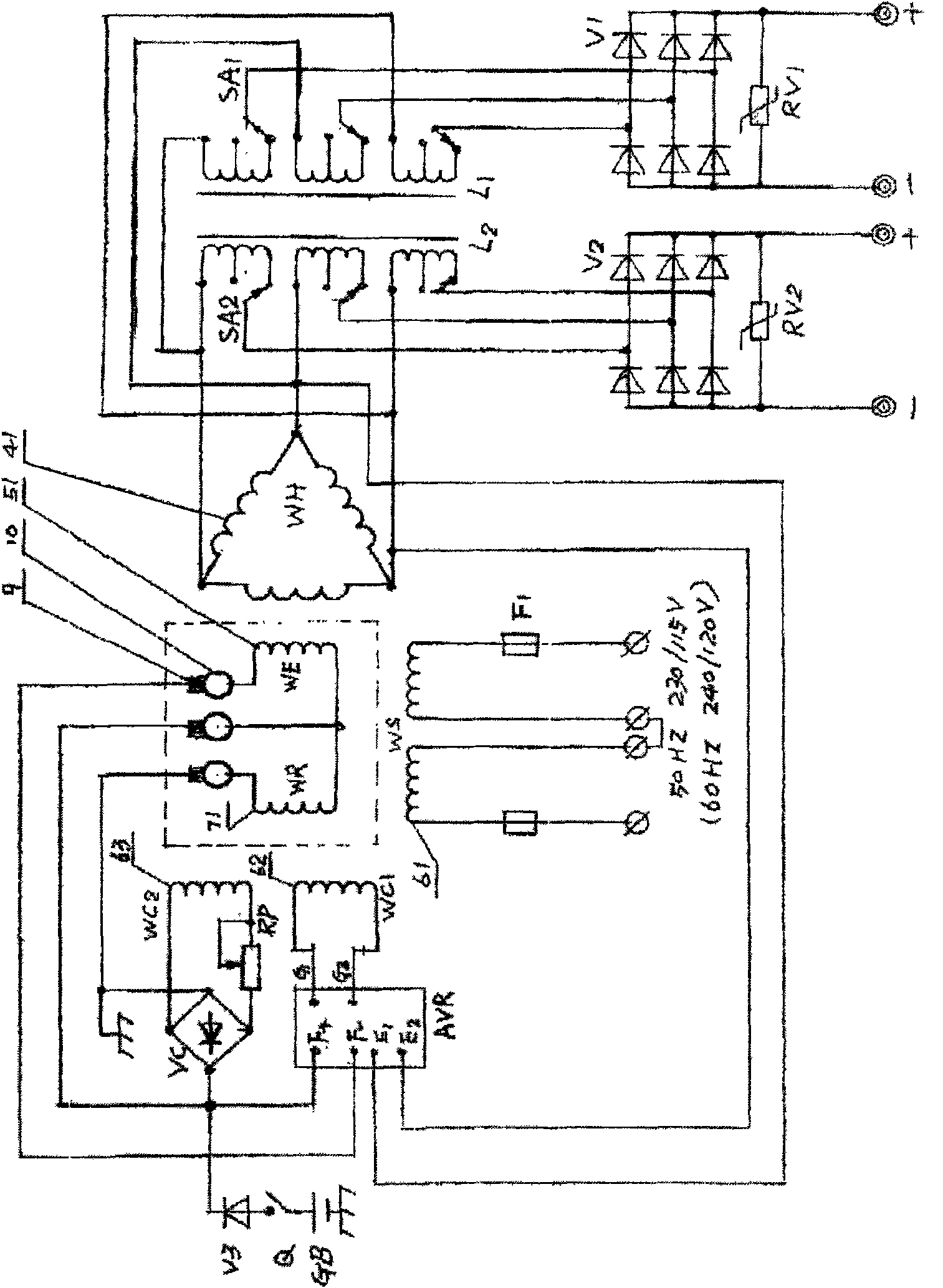

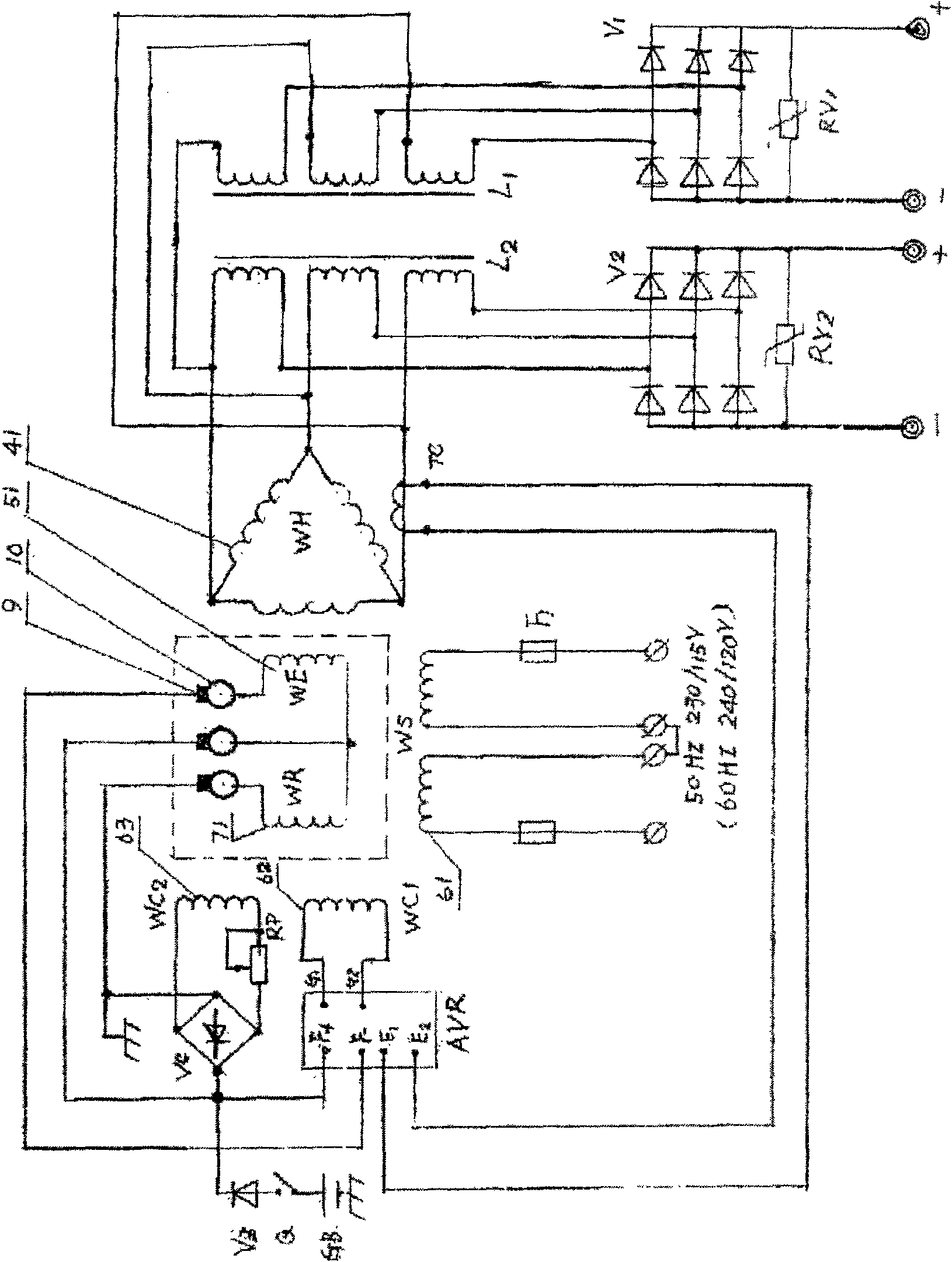

[0015] figure 1 It is a longitudinal section structure diagram of the double-torch electric welding-generating dual-purpose machine of the present invention. Such as figure 1 shown and combined with figure 2 , the dual-purpose electric welding and power generation machine of the present invention is a dual-motor structure generator, which is composed of a main generator and an auxiliary generator whose magnetic circuits and circuits are independent of each other, and the rotors of the main and auxiliary generators are placed on the same rotating shaft 1 , the main generator stator 4 is placed in the machine base 3, the auxiliary generator stator 6 is fixed on the flange of the end cover 8, the main generator stator 4 is embedded with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com