Photomultiplier pinhole detector

A photomultiplier tube and detector technology, applied in the field of detectors, can solve the problems of food manufacturers such as economic or reputation loss, low precision, food contamination, etc., and achieve high detection accuracy and efficiency, fast time response, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

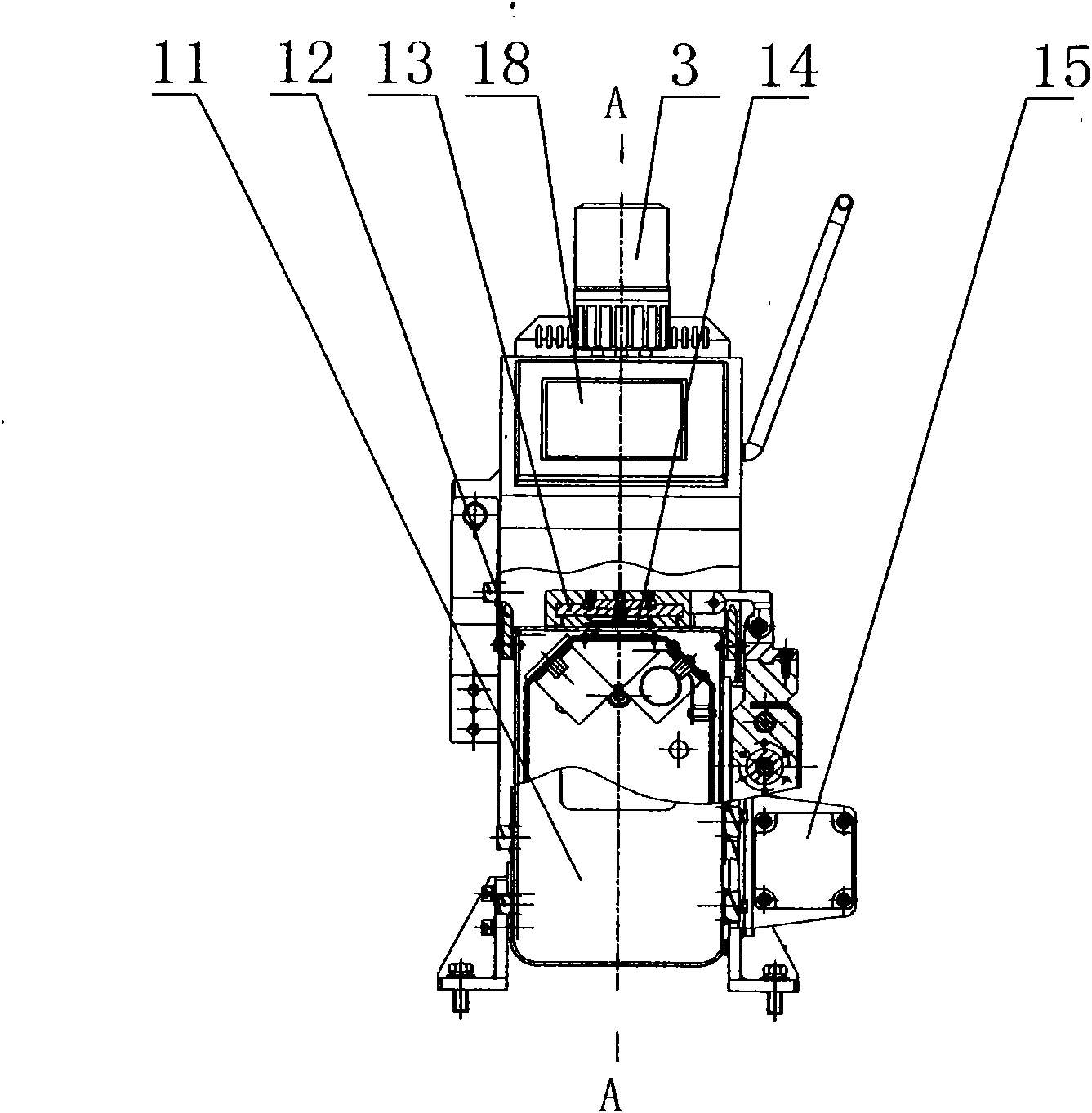

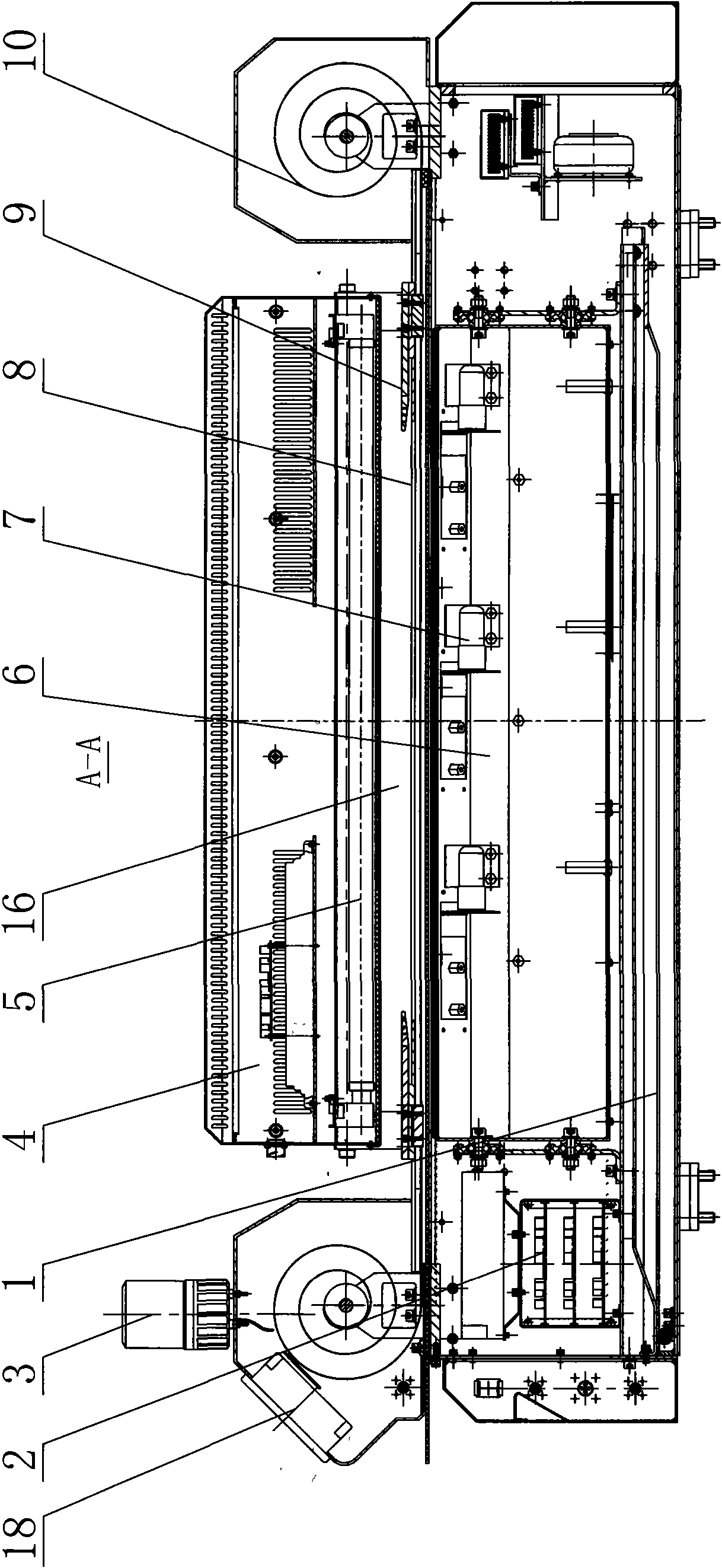

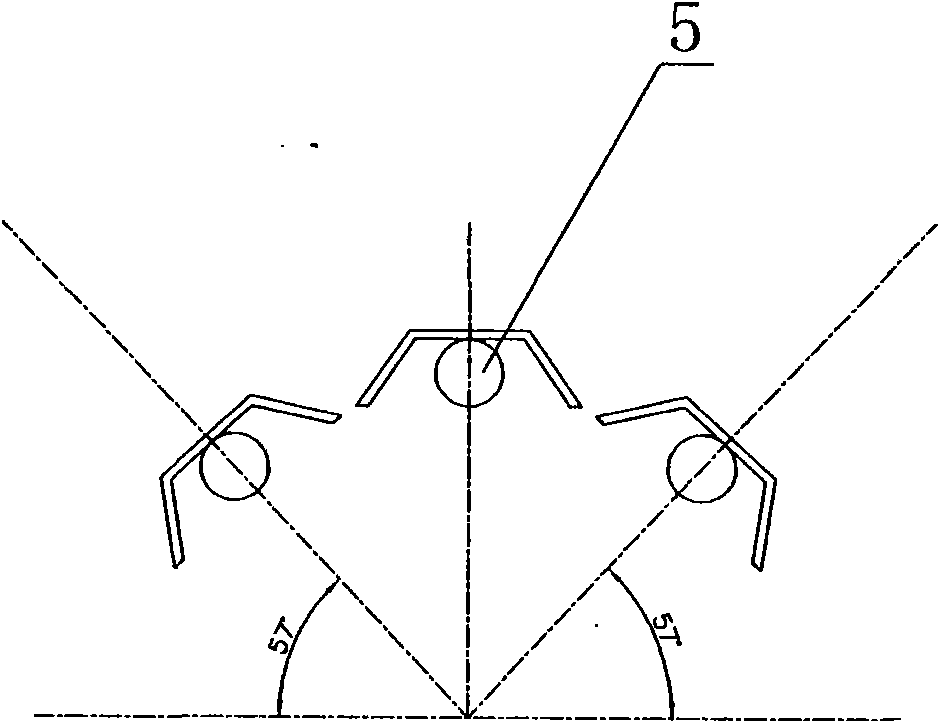

[0016] like figure 1 , figure 2 As shown, the photomultiplier tube pinhole detector described in this embodiment mainly includes a frame 1 and a power supply. A light box 4 is provided, and three ultraviolet lamp tubes 5 are arranged in the light box 4, wherein one ultraviolet lamp tube 5 is vertically irradiated, and the other two ultraviolet lamp tubes 5 are arranged symmetrically and form an angle of 57 degrees with the horizontal, such as image 3 shown. A detection area 16 is provided between the light-shielding anti-scratch bracket 12 and the light box 4; the main box body 11 fixed on the frame 1 is on the lower side of the light-shielding anti-scratch bracket 12, and a dark box is arranged inside the main box body 11. 6, such as Figure 4 As shown, the upper part of the dark box 6 is provided with a light inlet 19, the light inlet 19 is provided with a plexiglass dustproof cover 14, the inner wall of the dark box 6 is provided with a reflective layer 17, and the dar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com