Outer cover glass tube lens focusing narrowing and variable diameter all-glass vacuum heat collector tube

A technology of vacuum heat collecting tubes and glass tubes, which is applied in the field of solar energy applications, can solve the problems of low heat collection efficiency and light leakage of all-glass vacuum heat collecting tubes, and achieve the effect of improving heat collection efficiency and solving light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

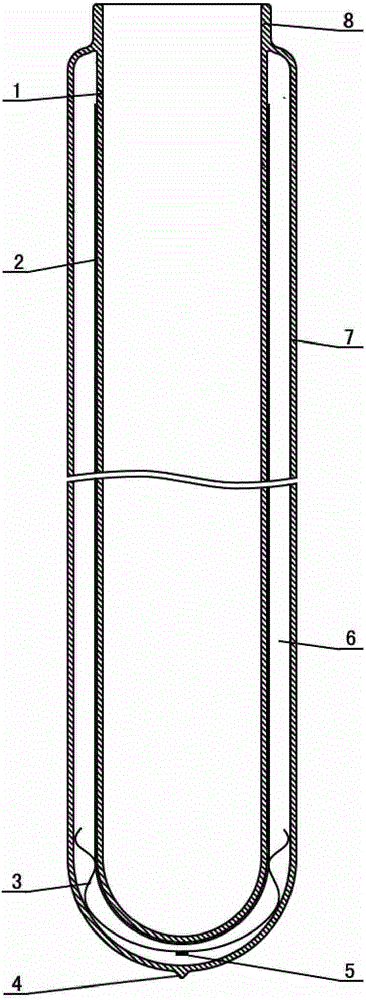

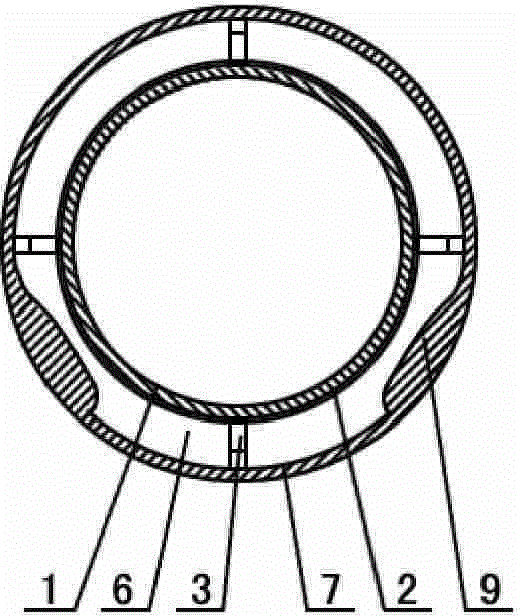

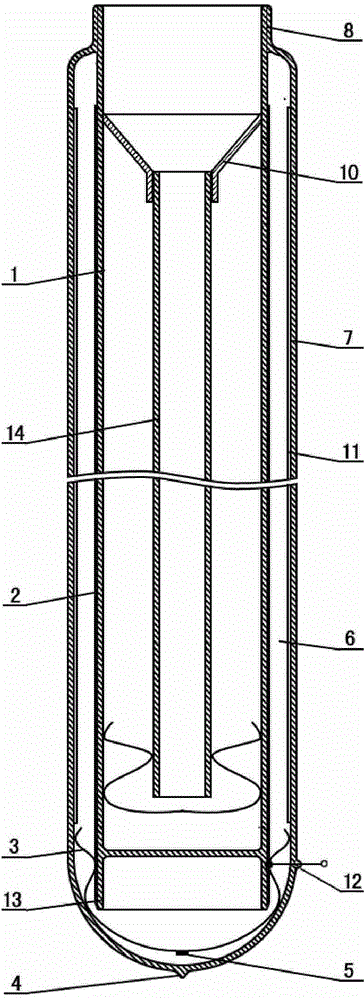

[0025] Such as figure 1 , 2 As shown: the outer cover glass tube lens focusing shrinkage and variable diameter all-glass vacuum heat collecting tube, including the outer cover glass tube 7, the inner heat collecting glass tube 1, the support clip 3, the getter 5, and the exhaust nozzle 4. On the tube wall of outer cover glass tube 7, be provided with convex lens 9, and convex lens 9 is longitudinally located on the outer cover glass tube arc tube wall of both sides between outer cover glass tube diameter and parallel chord, and longitudinally is arranged with a pair of convex lens 9. The inner heat-collecting glass tube 1 is coated with heat-absorbing film 2, on the outer cover glass tube 7, the glass welding exhaust nozzle 4 is installed in the outer cover glass tube 7 with a support bullet 3 with getter 5, and then the inner heat-collecting glass The tube is set in the outer cover glass tube, the outer cover glass nozzle, the inner heat collecting glass nozzle, and the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com