Lens drive device

A lens drive device and lens technology, applied in the field of photography, can solve the problems of weak magnetic field and low magnetic field utilization rate, and achieve the effects of reduced magnetic flux leakage, increased magnetic field utilization rate, and enhanced magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems to be solved, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

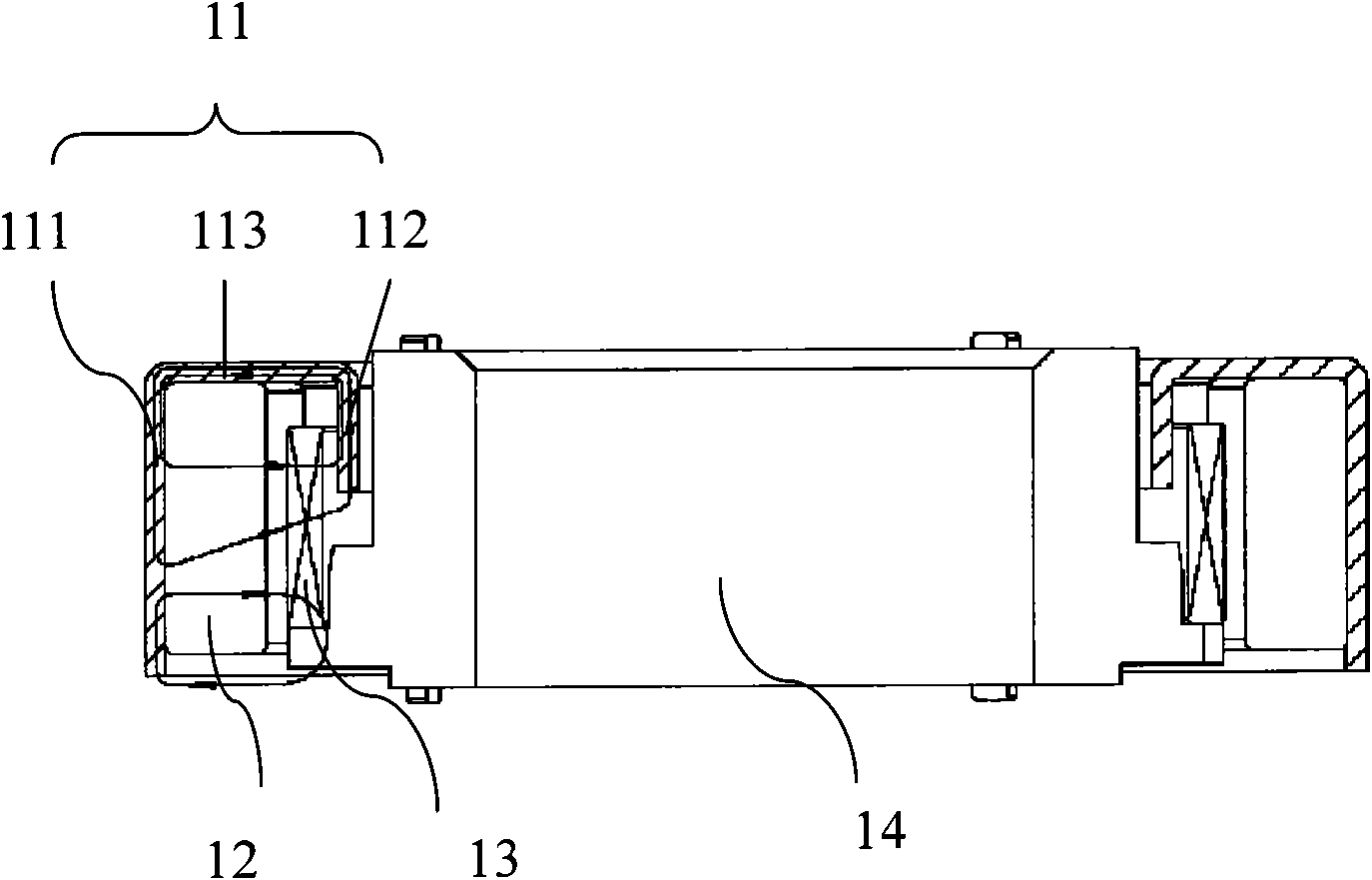

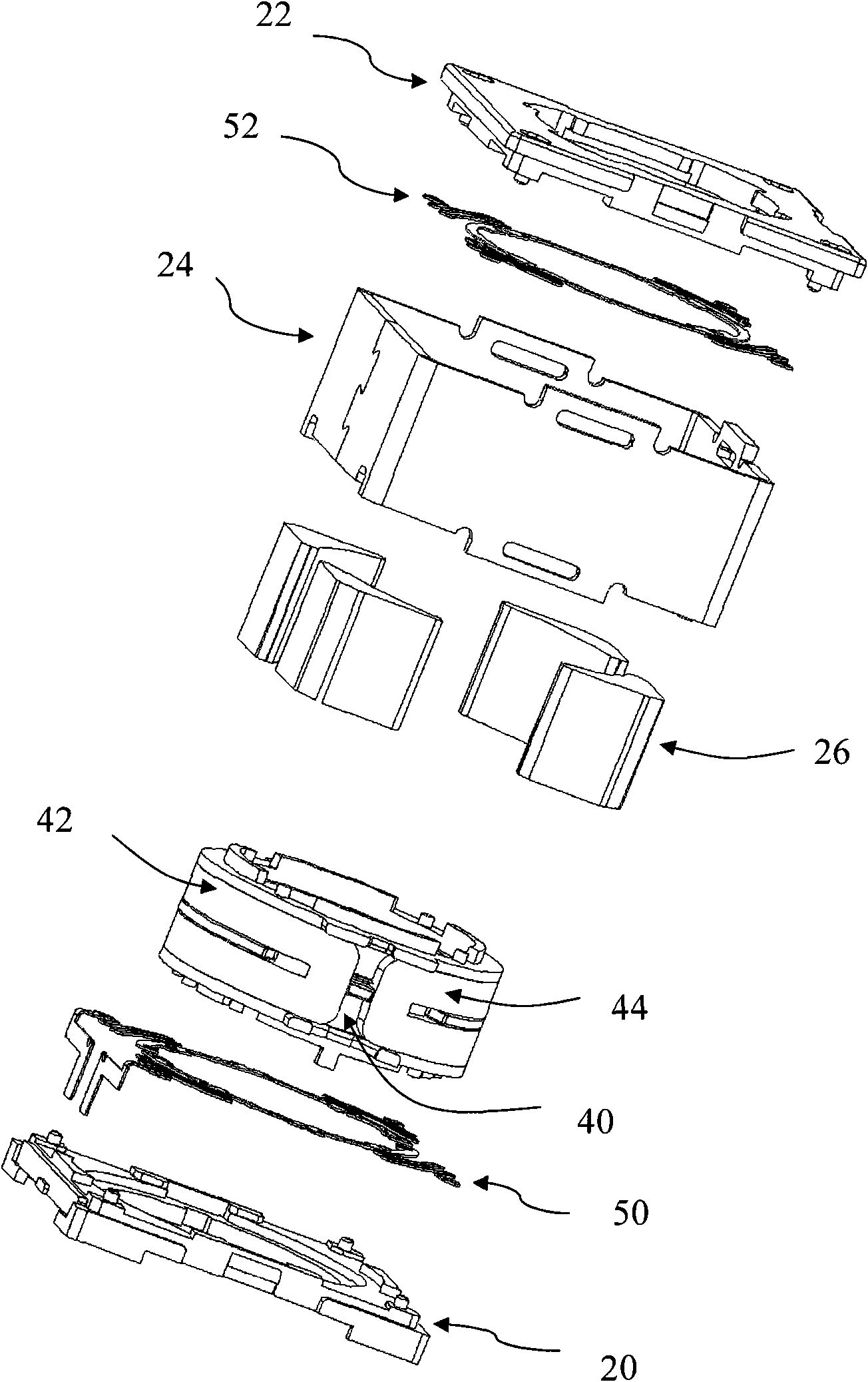

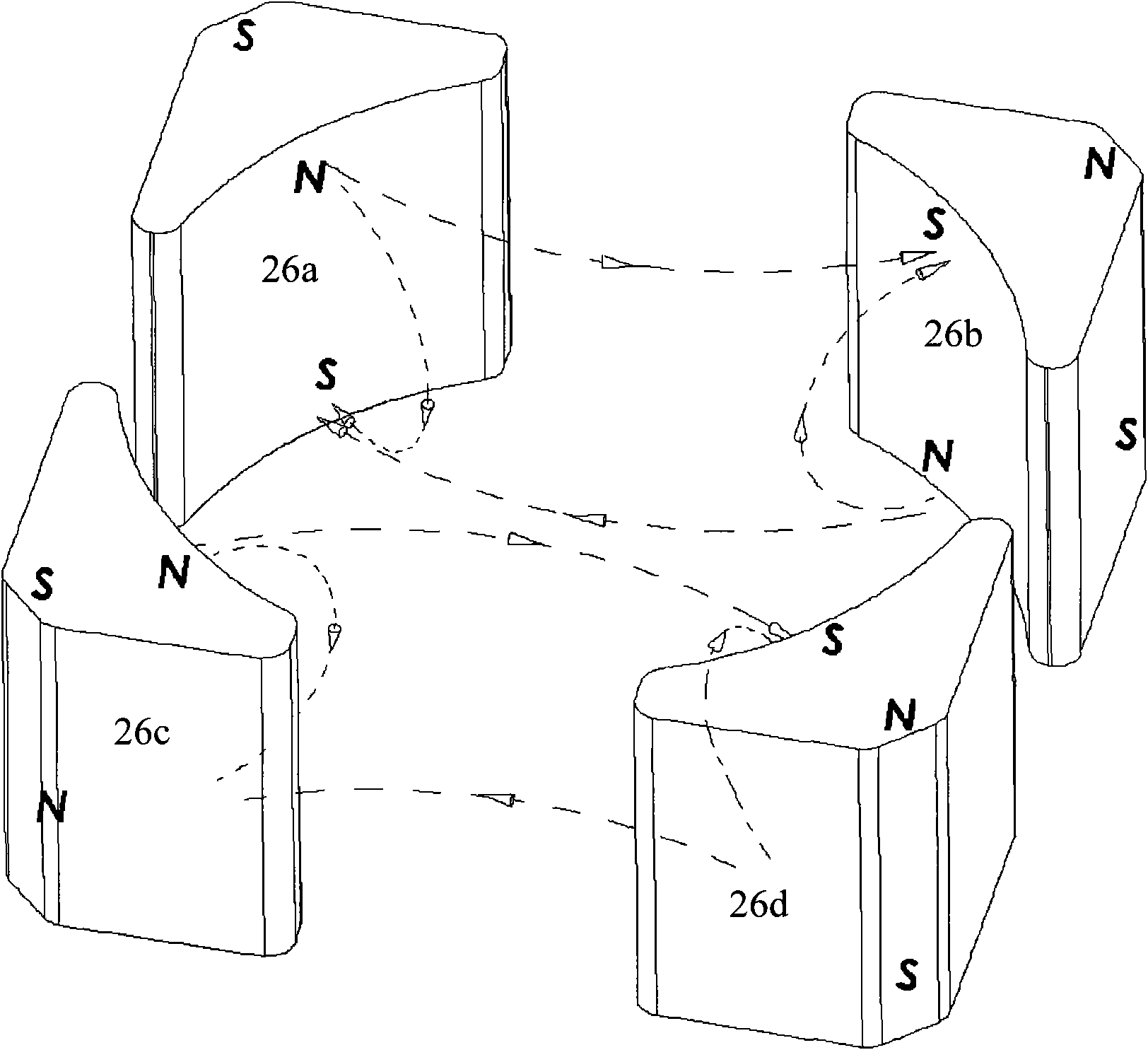

[0017] A lens driving device provided by an embodiment of the present invention includes a stationary part, a moving part, and a driving part for driving the moving part to move relative to the stationary part along the optical axis of the lens. The driving part includes a plurality of magnets fixed on one of the stationary part and the moving part, and at least two coils fixed on the other of the stationary part and the moving part, facing the magnet. For the convenience of description, the magnets in the following embodiments are fixed to the stationary part, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com