Rotary quick-opening device for pressure vessel

A door-opening device and pressure vessel technology, which is applied to pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of easy wear and tear of sealing rings, complex fixing structure of quick-opening lids, etc., and achieve manufacturing cost reduction and fixed structure requirements little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

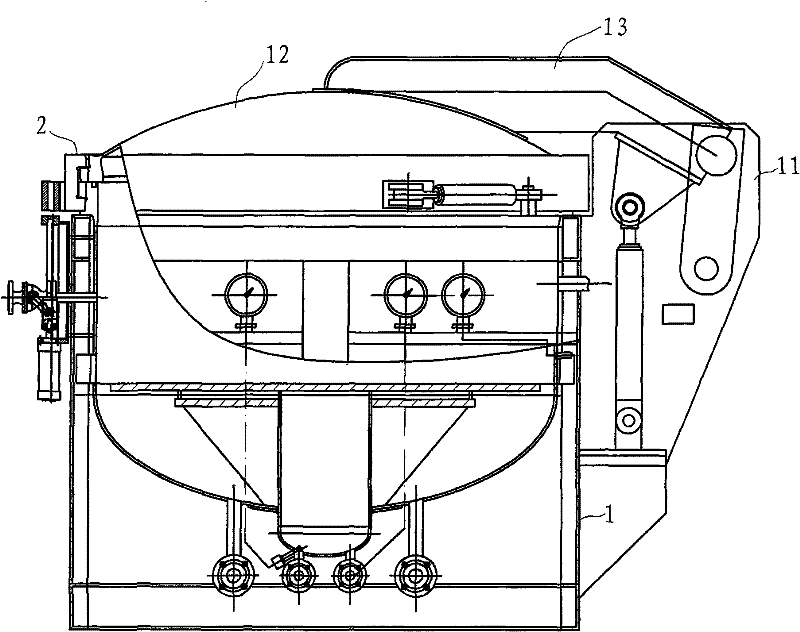

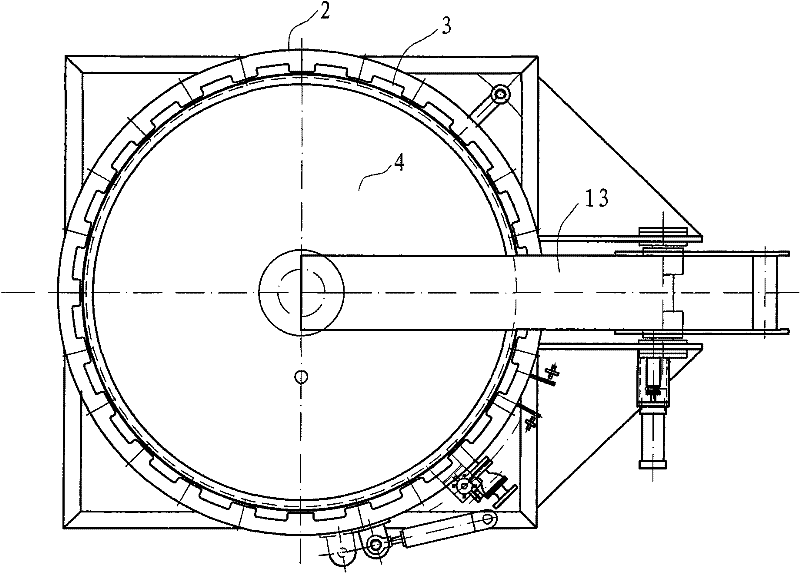

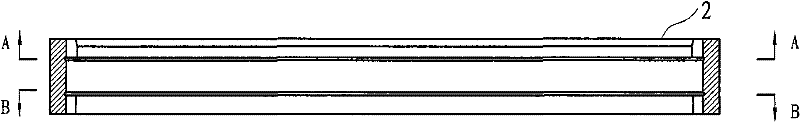

[0022] Such as Figure 1 to Figure 7 As shown, the pressure vessel in this embodiment is a vulcanization tank, including a tank body 1, a head 4, a rocker arm 13, a rotating ring 2, an upper flange 3, and a lower flange 5, and the upper flange 3 is located at the bottom of the head 4. The port forms a quick-opening cover 12, which is fixed on one end of the rocker arm 13 and can be lifted up and down, while the other end of the rocker arm 13 is rotatably set on the side 11 of the tank body, and the lower flange 5 is connected to the tank body 1 port.

[0023] The upper flange 3 is evenly distributed with upper flange teeth 31 along the circumferential direction, and the lower flange 5 is evenly distributed with lower flange teeth 51 along the circumferential direction. For the cover 12 and the tank body 1, the upper end of the rotating ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com