Compound ammonium bicarbonate additive and production method thereof

A production method and additive technology, applied in the direction of ammonium carbonate/acid carbonate, etc., can solve the problems of high water content and high price, and achieve the effects of easy storage, increased crystal particles, and improved product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

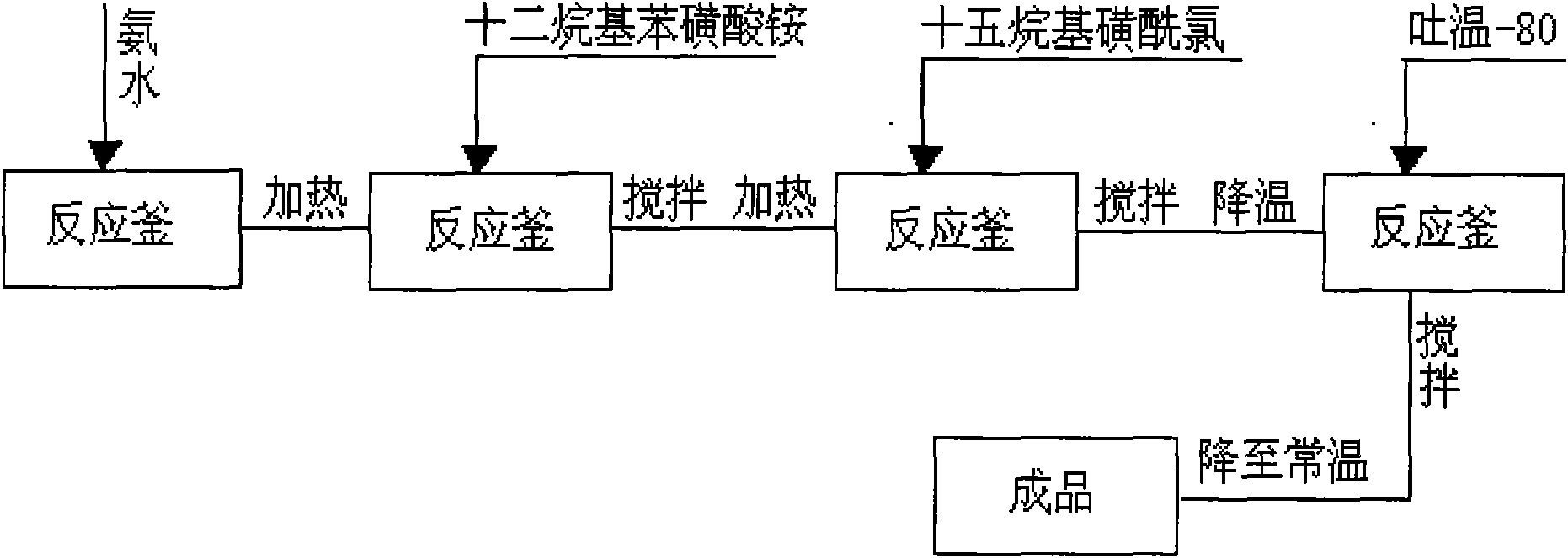

[0014] Example 1: Ammonia water with a mass concentration of 4%, ammonium dodecylbenzenesulfonate, pentadecylsulfonyl chloride, and Tween-80 were prepared in sequence in the proportion of 45:13:28:3 by weight. Then add ammonia water to the heating reaction kettle, add ammonium dodecylbenzenesulfonate when the temperature reaches 58°C, stir the mixture of the two fully, add pentadecylsulfonyl chloride when the temperature of the reaction kettle reaches 70°C, and stir again After 55 minutes, when the temperature was naturally lowered to 58°C, Tween-80 was added, fully stirred evenly, and the temperature was naturally lowered to room temperature to obtain the finished product.

Embodiment 2

[0015] Example 2: Ammonia water with a mass concentration of 6%, ammonium dodecylbenzenesulfonate, pentadecylsulfonyl chloride, and Tween-80 were prepared in sequence in the proportion of 50:14:30:5 by weight. Then add ammonia water to the heating reactor, add ammonium dodecylbenzenesulfonate when the temperature reaches 61°C, stir the mixture of the two fully, add pentadecylsulfonyl chloride when the temperature of the reactor reaches 76°C, and stir again After 65 minutes, when the temperature was naturally lowered to 60°C, Tween-80 was added, fully stirred evenly, and the temperature was naturally lowered to room temperature to obtain the finished product.

Embodiment 3

[0016] Example 3, ammonia water with a mass concentration of 8%, ammonium dodecylbenzenesulfonate, pentadecylsulfonyl chloride, and Tween-80 were prepared in sequence in the proportion of 55:15:32:6 by weight. Then add ammonia water to the heating reactor, add ammonium dodecylbenzenesulfonate when the temperature reaches 62°C, stir the mixture fully, add pentadecylsulfonyl chloride when the temperature of the reactor reaches 78°C, and stir again After 70 minutes, when the temperature was naturally lowered to 62°C, Tween-80 was added, fully stirred evenly, and the temperature was naturally lowered to room temperature to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com