Method for operating a printing press

A printing machine and working mode technology, applied to printing machines, general parts of printing machinery, rotary printing machines, etc., can solve problems such as reducing printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

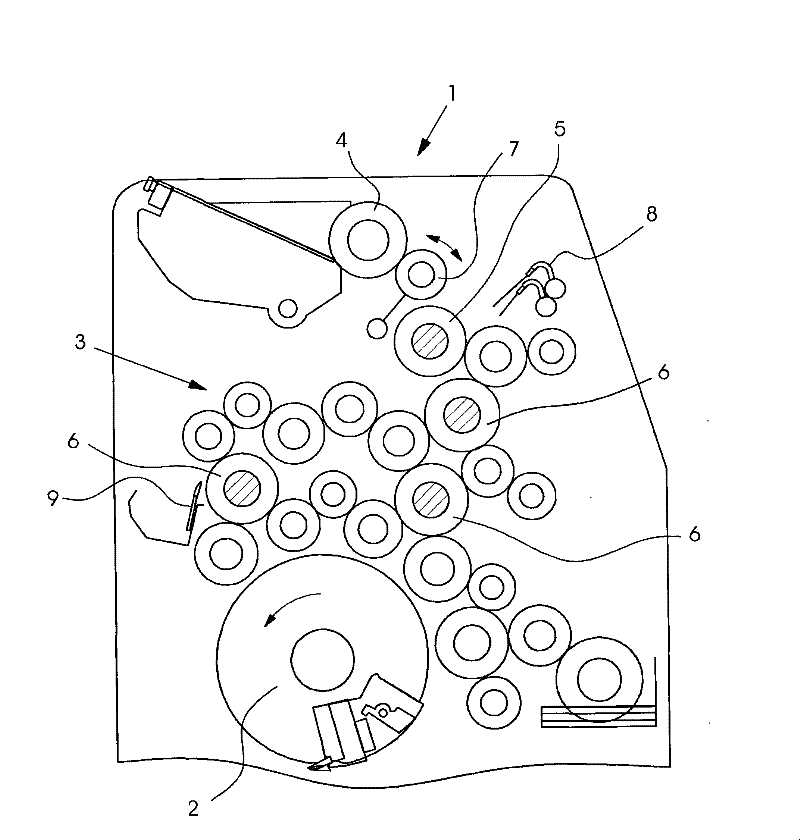

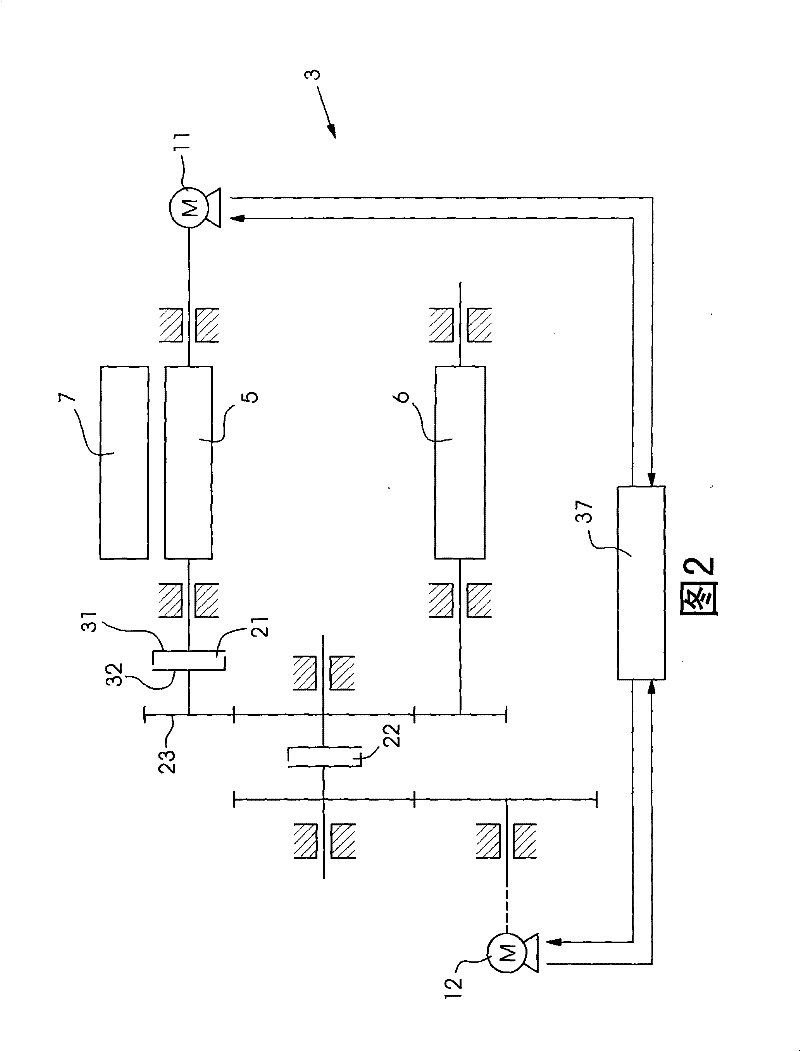

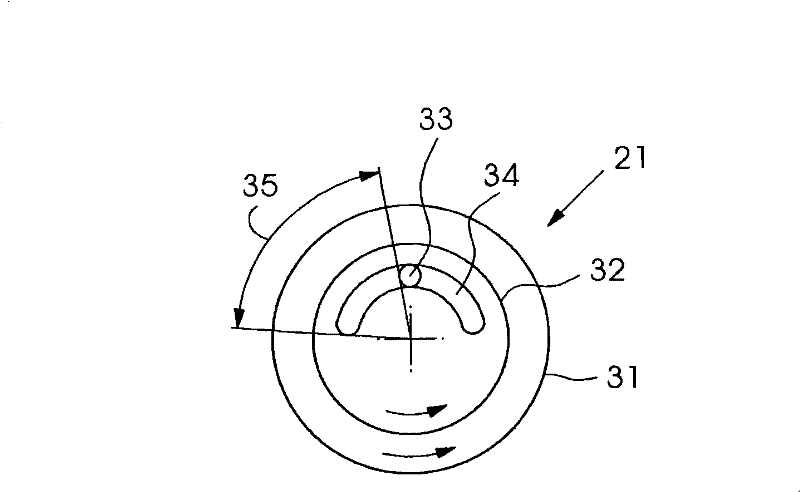

[0021] figure 1 A printing press 1 for printing sheets is shown in detail. The detail shows a printing unit for offset printing. The printing unit comprises an impression cylinder and a blanket cylinder, which are not shown in the figures. Furthermore, the printing unit comprises a printing form cylinder 2 , a dampening unit (not shown in detail) for wetting the printing form cylinder 2 and an inking unit 3 for inking the printing form cylinder 2 . The inking unit 3 is a roller inking unit and comprises an ink fountain with a fountain roller 4 , a first roller 5 , second rollers 6 and further rollers not shown in detail, including transfer rollers and ink form rollers. The second rollers 6 are rotationally driven by gears which are arranged concentrically with the second rollers 6 and are connected in a rotationally fixed manner. These gears are a transmission 23 (see figure 2 )made of. In addition, the inking unit 3 includes an inking roller 7 , which pivots back and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com