Antenna and manufacturing method thereof

An antenna and organometallic technology, which is applied in the manufacture of antennas, antenna components, and printed circuits, can solve problems such as poor antenna accuracy, and achieve the effects of high design freedom, reduced production costs, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment illustrates the antenna of the present invention and its manufacturing method.

[0032] Using Ultramid plastic produced by BASF Company (the plastic base material is aromatic polyamide) as raw material, an injection molding machine (TOYO Company, Model 100T) is used to prepare a mobile phone antenna bracket, which contains an organic metal compound The thickness of the layer of plastic is 1.3 mm.

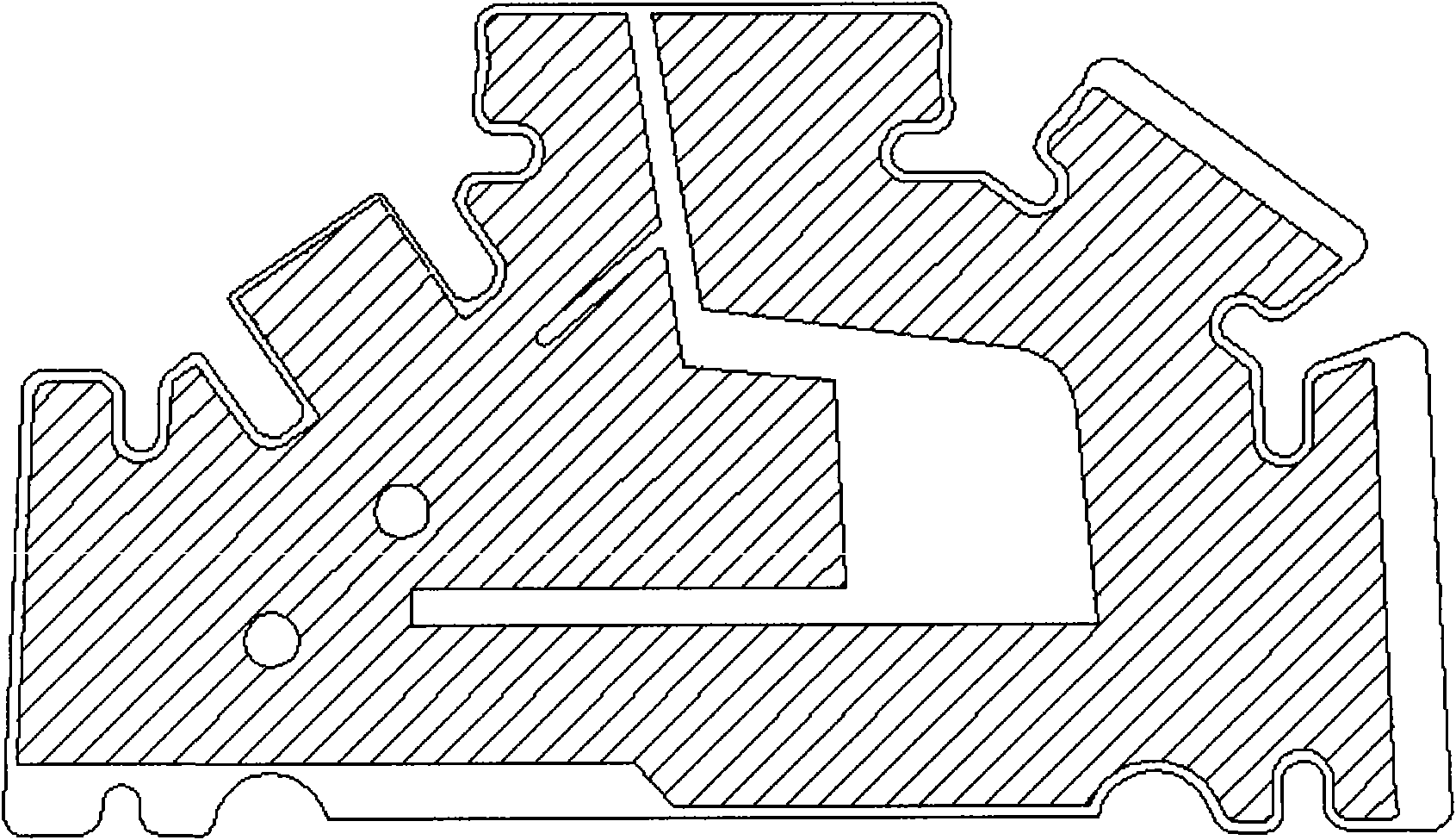

[0033] Use a laser machine (Tide laser machine, model DPY-M50) to irradiate the surface of the bracket with laser light to form a groove (the shape of the groove is as follows figure 1 Shown in the shaded part of ), the depth of the groove is 0.05 mm.

[0034] Wash the stent after laser irradiation with water. Then take the support as the cathode, and copper as the anode, electroplating in the electroplating solution, the composition of the electroplating solution and the content of each component are: copper sulfate of 1.8 grams per liter, sodium hydroxide ...

Embodiment 2

[0036] This embodiment illustrates the antenna of the present invention and its manufacturing method.

[0037] ABS / PC plastics (acrylonitrile-butadiene-styrene copolymer / polycarbonate) produced by Pocan plastics produced by Bayer Corporation (the plastic base material is polybutylene terephthalate) and GE Corporation As raw material, prepare the support of mobile phone antenna by two-color injection molding machine (Farrack (FUNAC) company, two-color machine model 100T), the described support that obtains comprises the plastics that contains organometallic compound and does not contain organometallic compound Plastic, the thickness of the plastic containing the organic metal compound is 0.5 mm, and the thickness of the plastic not containing the organic metal compound is 0.8 mm.

[0038] Use a laser machine (Tide laser machine, model DPY-M50) to carry out laser irradiation on the surface of the plastic layer containing the organometallic compound of the bracket, and form groov...

Embodiment 3

[0041] This embodiment illustrates the antenna of the present invention and its manufacturing method.

[0042] The Bayblend plastic (the plastic substrate is ABS / PC) produced by Bayer / Albis company and the ABS / PC plastic (acrylonitrile-butadiene-styrene copolymer / polycarbonate) produced by GE company are raw materials, Prepare the support of the mobile phone antenna by a two-color injection molding machine (Faraq (FUNAC) company, two-color machine model 100T), and the obtained support includes plastics containing organometallic compounds and plastics that do not contain organometallic compounds, so The thickness of the plastic containing the organometallic compound is 0.5 mm, and the thickness of the plastic not containing the organometallic compound is 0.8 mm.

[0043] Use a laser machine (Tide laser machine, model DPY-M50) to carry out laser irradiation on the surface of the plastic layer containing the organometallic compound of the bracket, and form grooves (concaves) on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com