Stirring type asphalt melting tank

A melting tank and mixing technology, applied in the field of mixing asphalt melting tanks, can solve the problems of increasing manpower and financial resources of the construction party and slowing down the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

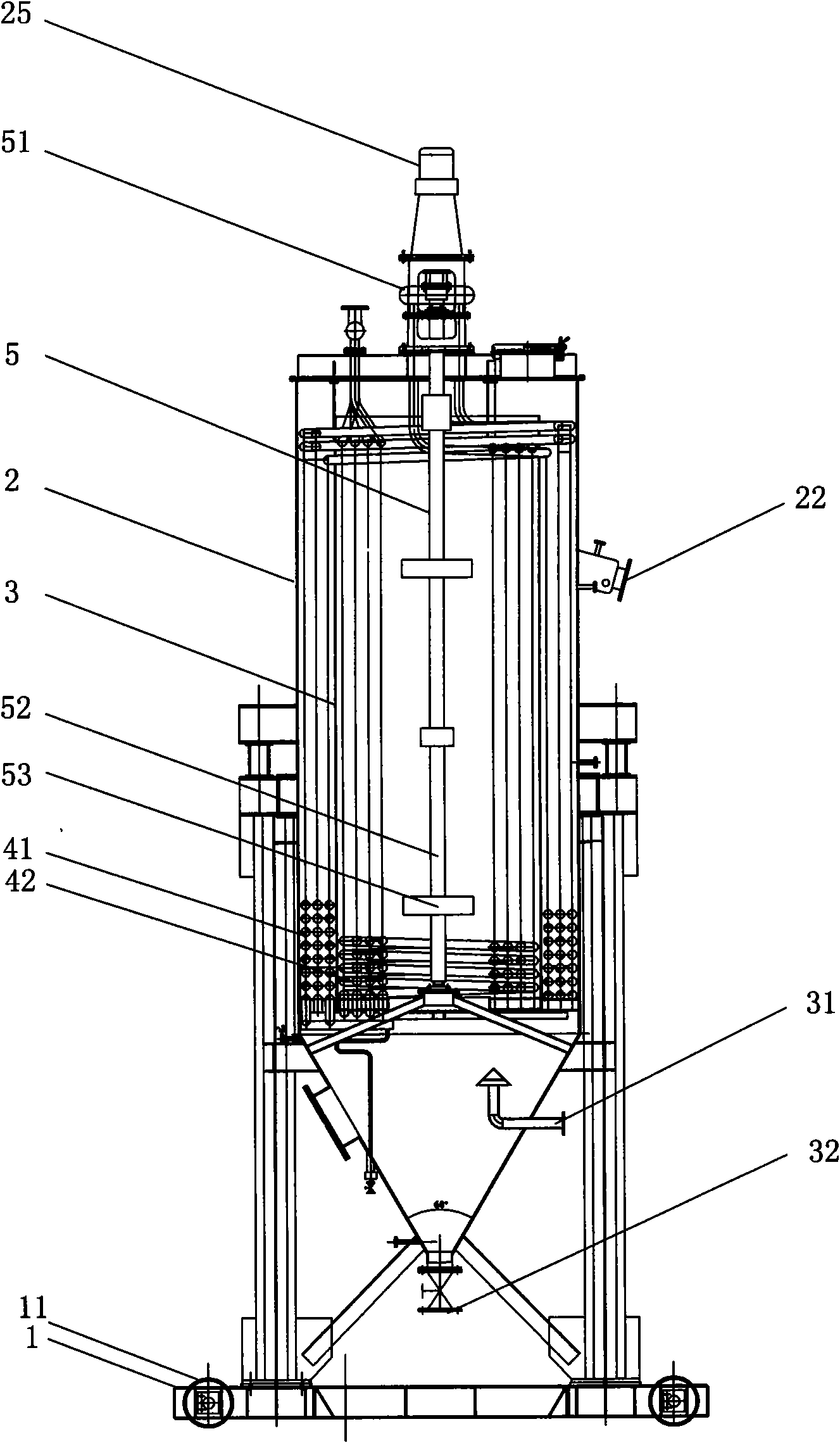

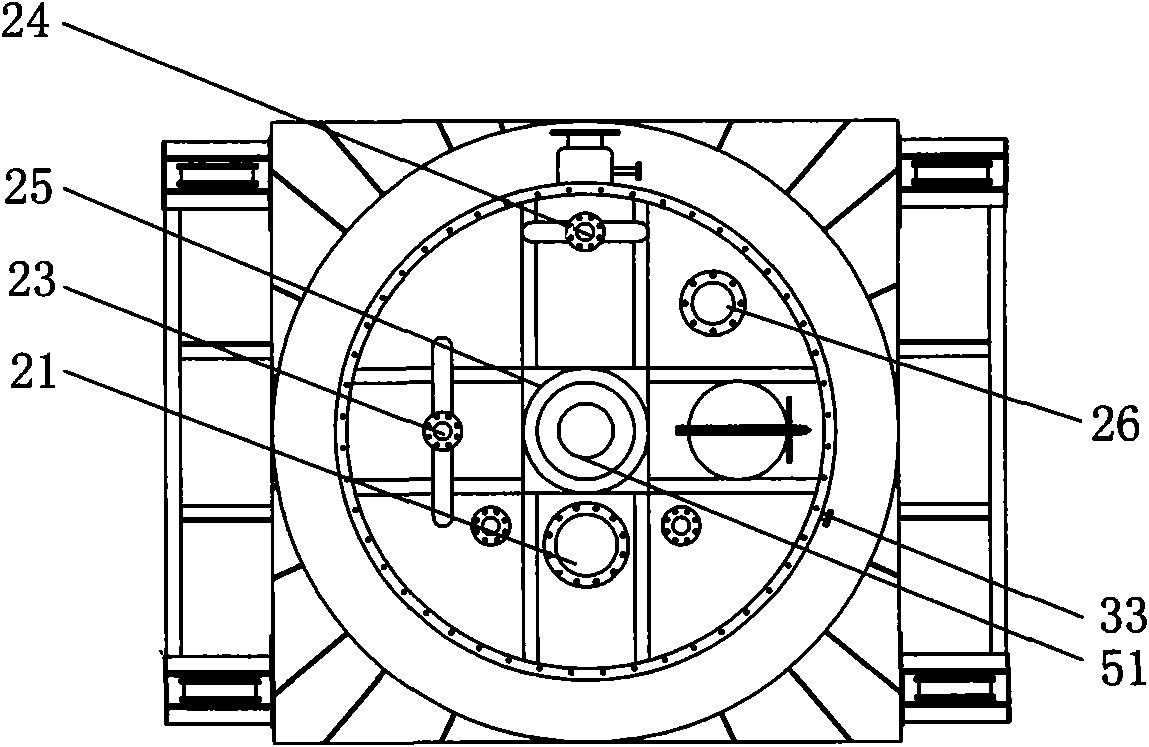

[0007] The invention is mainly composed of five parts: a machine base (1), an outer cylinder (2), an inner cylinder (3), a heating device (4) and a stirring device (5). 4 rollers (11) are installed on the base (1) to facilitate the movement of the device; there is an asphalt outlet (22) on the side of the outer cylinder (2), and an asphalt feed port (21) and a heat transfer oil inlet (23) are provided on the top. ), the heat transfer oil outlet (24) and the asphalt upper inlet (25), the coil heating device (41) that can pass into the high temperature heat transfer oil is placed inside the outer cylinder (2); the inner cylinder (3) A coil heating device (42) that can be fed with high-temperature heat transfer oil is placed inside, and the bottom of the inner cylinder (3) is provided with an asphalt lower outlet (31) and a slag discharge port (32), and the inner cylinder (3) A stirring device (5) is installed on the top, and the stirring device (5) is composed of a transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com