Electromagnetic wire coil, manufacturing method thereof and induction cooker with wire coil

A manufacturing method and technology of electromagnetic wire, applied in the field of induction cooker and induction cooker, can solve the problems of increasing the assembly operation process, cannot be realized at the same time, reducing work efficiency, etc., so as to reduce the process of assembling the magnetic strip, and reduce the production cost and material cost of the product. , the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

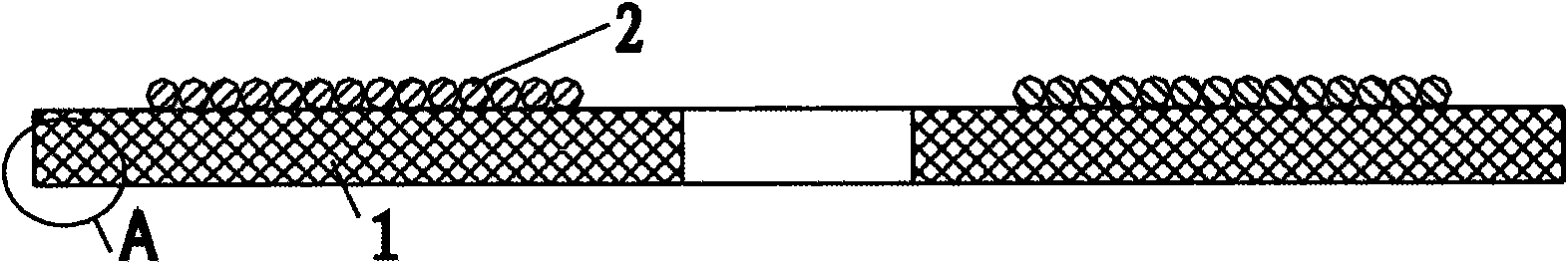

[0019] like figure 1 As shown, it is the first embodiment of the electromagnetic wire reel of the present invention. The electromagnetic wire reel includes a wire reel frame 1 and a coil 2. Compared with the existing electromagnetic wire reel, the electromagnetic wire reel cancels the magnetic strip. The setting is to achieve the effect of magnetic concentration by dispersing and setting magnetic objects in the wire tray rack.

[0020] like image 3 As shown, it is a schematic diagram of the internal structure of the electromagnetic wire reel rack 1 of the present invention. The wire reel rack 1 includes magnetic objects 11 and rack material 12 . The wire reel frame 1 can be prepared by the following method: firstly mix the magnetic substance 11 and the adhesive in a certain proportion, then mix the magnetic object 11 mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com