Oil and gas separating device

A separation device, oil and gas technology, applied in separation methods, dispersed particle separation, engine lubrication, etc., can solve problems such as insufficient separation of oil and gas, and achieve the effects of avoiding oil and gas channeling, close contact, and efficient oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

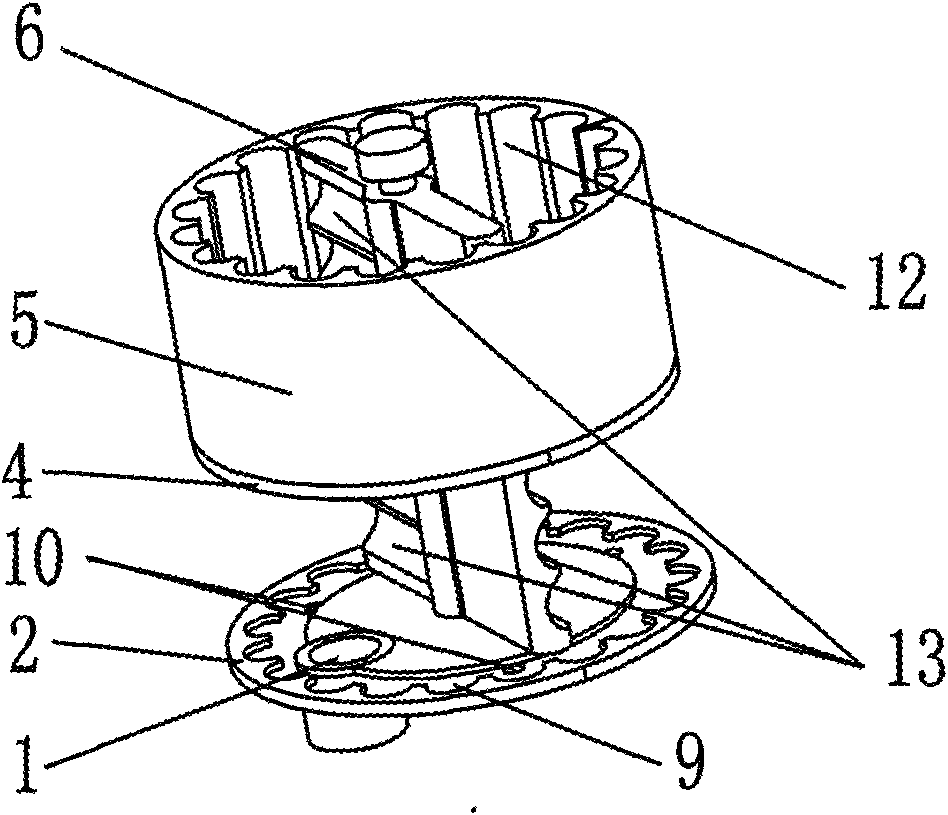

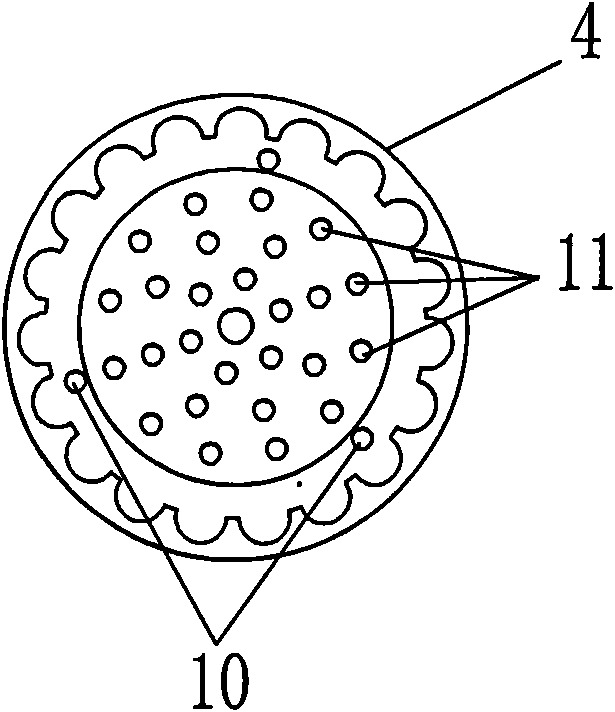

[0014] Example 1, such as figure 1 , 2 As shown in , 3, an oil-gas separation device includes a bottom plate 2 with an oil-gas inlet 1 and an oil return hole 10, a housing and a built-in rotor blade 6, and a cover plate 7 with an oil-gas outlet 8. The housing is divided into a first-level housing 3 and a second-level housing 5. The rotor blades 6 are also divided into upper and lower levels, and a partition 4 is arranged in the middle; the partition 4 is provided with a hole array 11 and Oil return hole.

Embodiment 2

[0015] Embodiment 2, in order to make the oil condense and adhere to the casing, the inner surfaces of the primary casing 3 and the secondary casing 5 are provided with tooth grooves 12 . All the other are with embodiment 1.

Embodiment 3

[0016] Embodiment 3, in order to make the oil condense on the rotor blades and flow to the casing to collect, the windward side of the rotor blades 6 is provided with radial oil guide grooves 13 . All the other are with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com