Protective cap, and electric tool with such a protective cap

A technology of electric tools and protective covers, applied in the field of protective covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

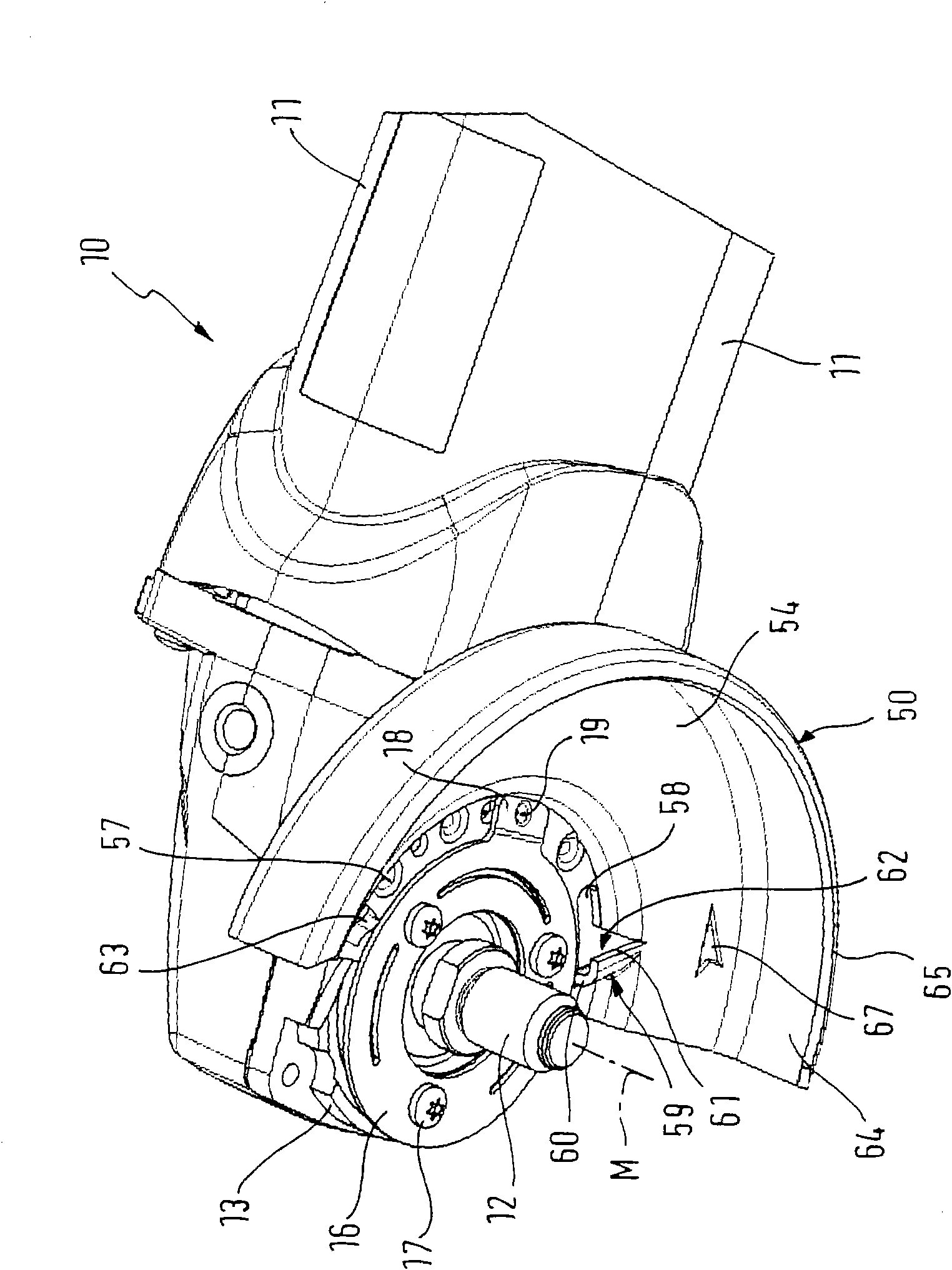

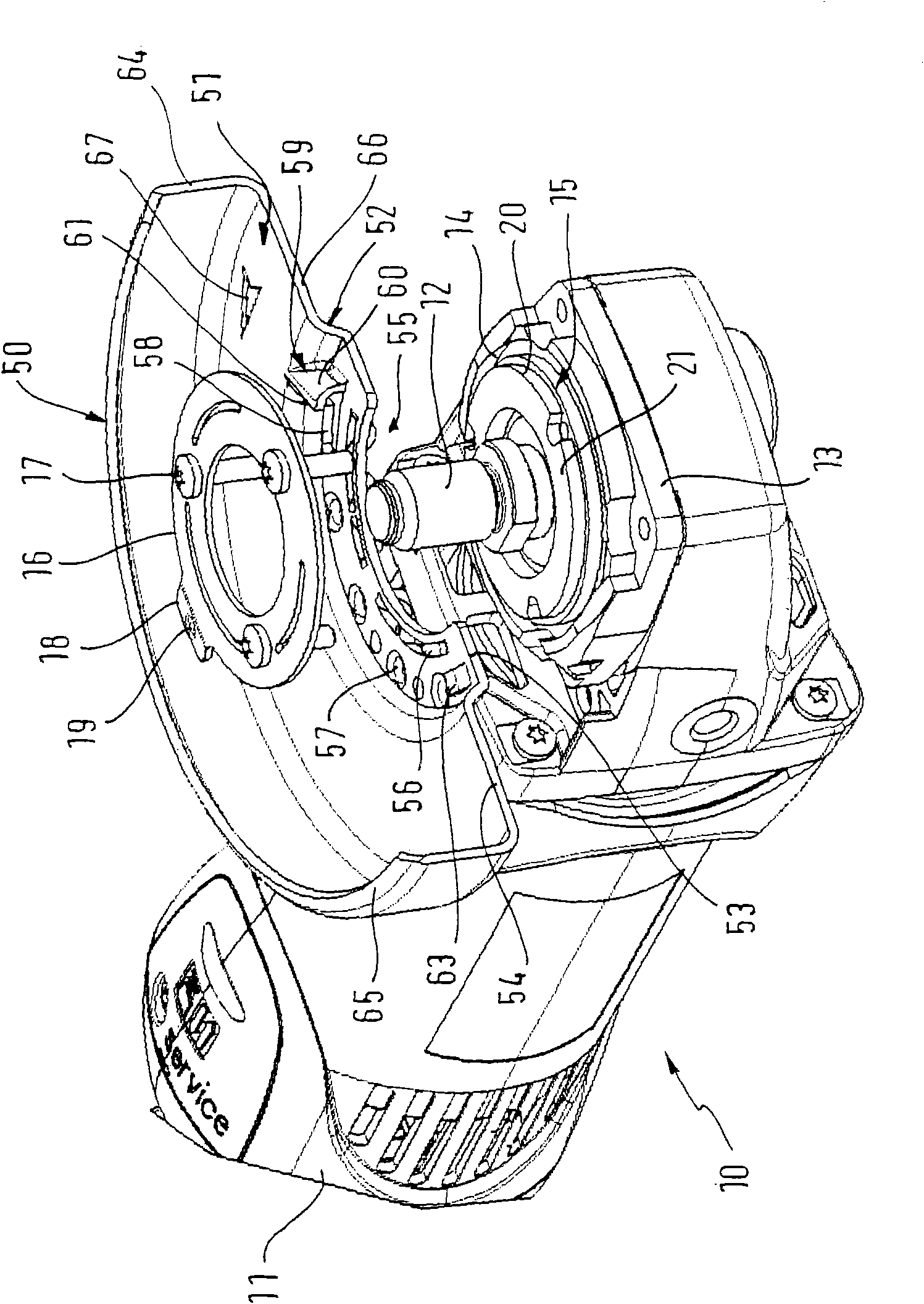

[0017] exist figure 1 and 2 The angle grinder shown in is an example of a power tool to which the invention can be applied. The angle grinder comprises a housing 11 in which a drive unit, which cannot be seen in the figures, is accommodated. A drive spindle 12 is rotated (here counterclockwise) by the drive, on which a grinding disc (not shown) can be fixed. exist figure 1 The central axis M of the drive spindle 12 is shown in . The drive spindle 12 is mounted in a housing 11 . The portion supporting the drive spindle is covered by an end shield 13 connected to the housing 11 . Formed in the end shield 13 is an annular groove 14 which is open in the front region 15 over an angular region of approximately 160°.

[0018] Furthermore, a retaining ring 16 formed from an elastic material, in particular a spring plate, is fastened in the end cap 13 by means of a screw connection 17 . The retaining ring 16 has, as a counter element, a projection 18 which is bent slightly downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com