Electrical scanner device and laser machining apparatus having electrical scanner device

An electrical scanner and filter technology, applied in laser welding equipment, metal processing equipment, instruments, etc., can solve the problems of increasing processing cost, increasing manufacturing cost, reducing the efficiency of device assembly operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An embodiment of the present invention will be described below using the drawings.

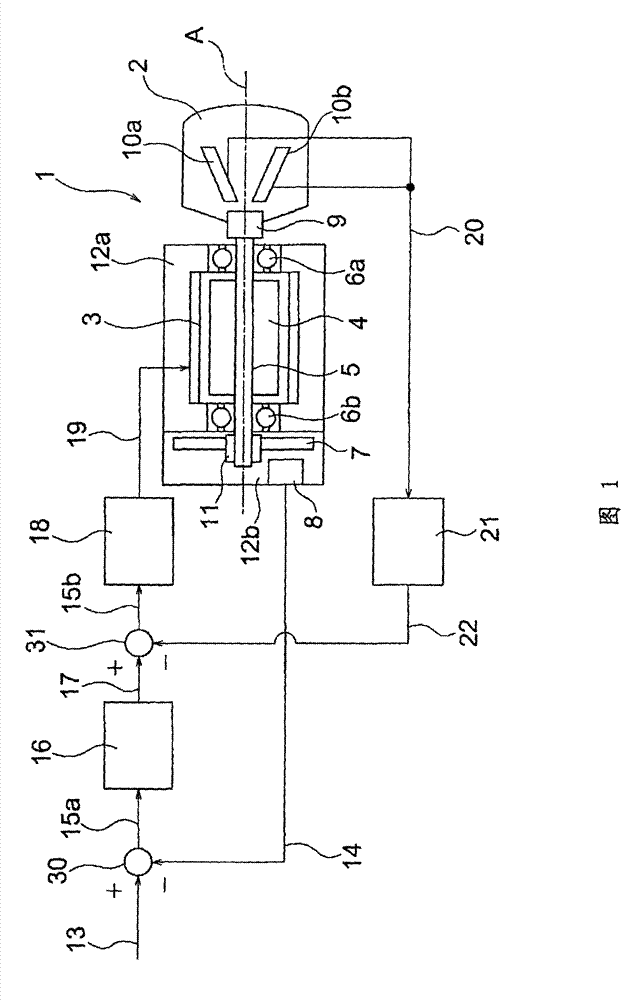

[0034] figure 1 It is a control block diagram of the galvano scanner device related to the present invention.

[0035] First, the schematic configuration of the galvano scanner device will be described.

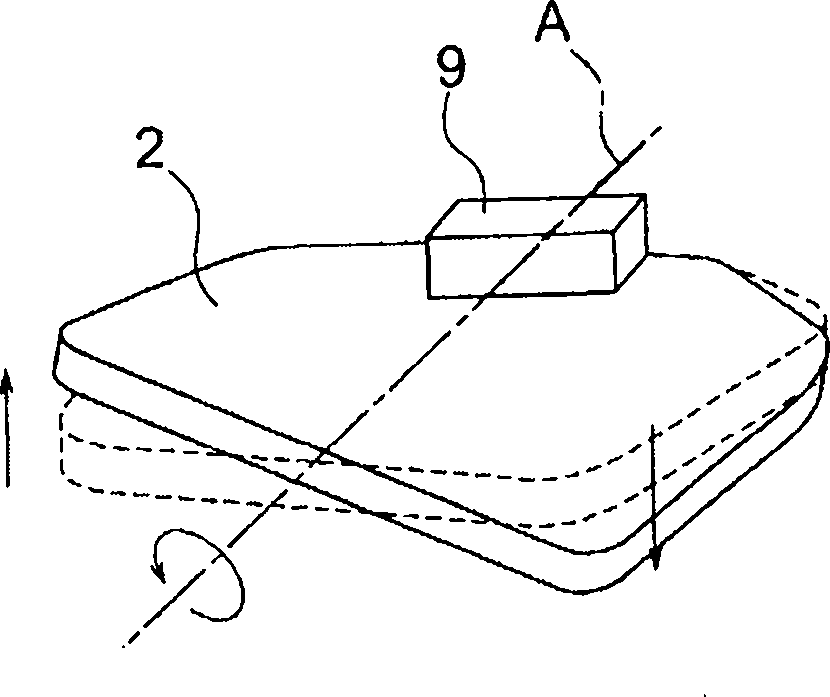

[0036] The rotary shaft 5 of the galvano scanner device 1 is supported by bearings 6a, 6b. On one end of the rotating shaft 5, the reflector 2 is fixed by the reflector holder 9, and two strain sensors 10a, 10b for detecting the amount of deformation of the reflector 2 are arranged on the back of the laser beam reflecting surface of the reflector 2. . In addition, since the strain sensors 10a and 10b have the same structure, they are simply referred to as the strain sensor 10 when there is no need to distinguish them. The strain sensor 10 outputs a strain detection signal 20 . The strain sensor 10 is a piezoelectric element such as PZT, a resistance wire strain gauge, or the like,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com